Popular Woodworking 2000-12 № 119, страница 12

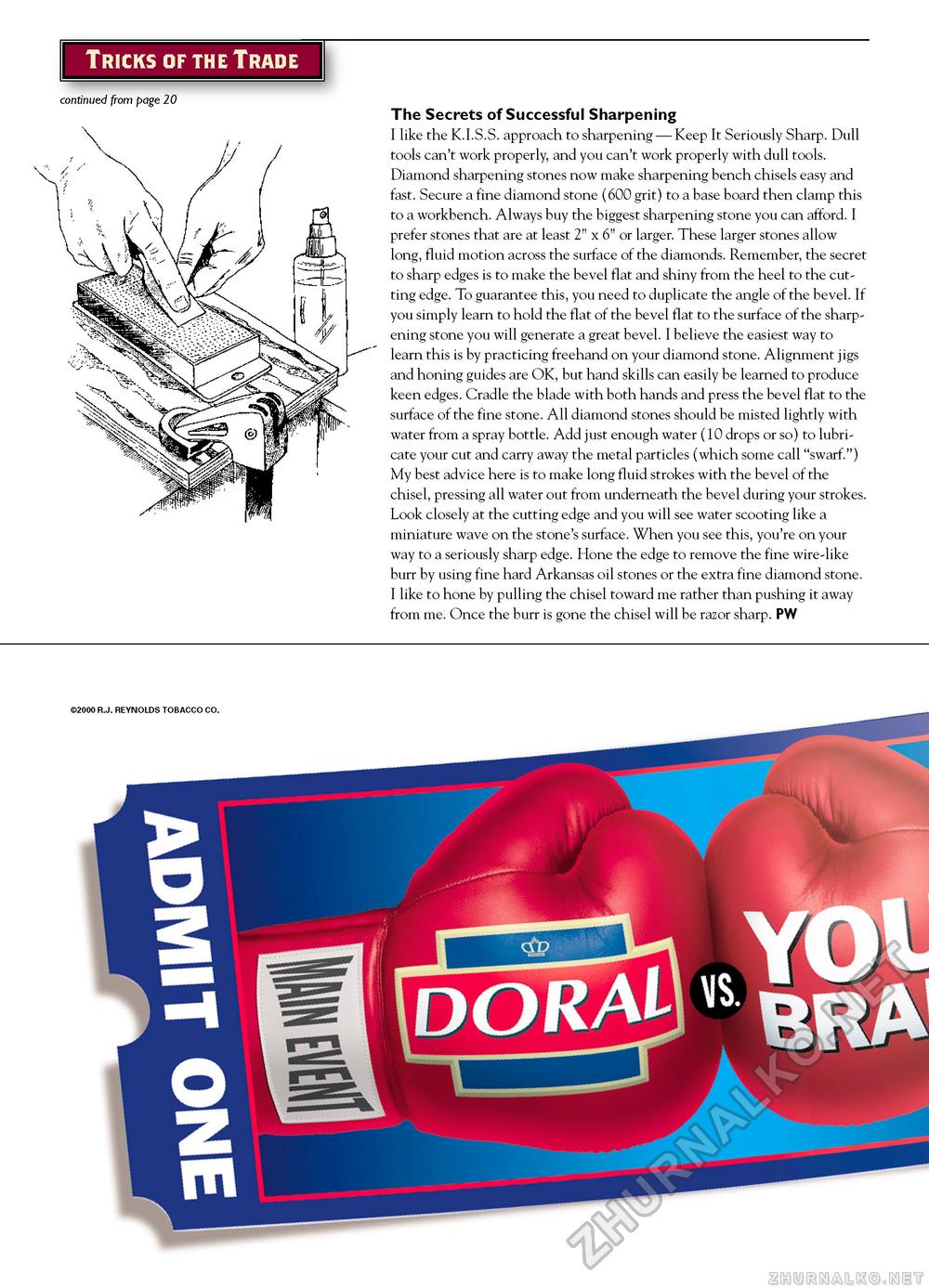

Tricks of the Trade continued from page 20 The Secrets of Successful Sharpening I like the K.I.S.S. approach to sharpening — Keep It Seriously Sharp. Dull tools can't work properly, and you can't work properly with dull tools. Diamond sharpening stones now make sharpening bench chisels easy and fast. Secure a fine diamond stone (600 grit) to a base board then clamp this to a workbench. Always buy the biggest sharpening stone you can afford. I prefer stones that are at least 2" x 6" or larger. These larger stones allow long, fluid motion across the surface of the diamonds. Remember, the secret to sharp edges is to make the bevel flat and shiny from the heel to the cutting edge. To guarantee this, you need to duplicate the angle of the bevel. If you simply learn to hold the flat of the bevel flat to the surface of the sharpening stone you will generate a great bevel. I believe the easiest way to learn this is by practicing freehand on your diamond stone. Alignment jigs and honing guides are OK, but hand skills can easily be learned to produce keen edges. Cradle the blade with both hands and press the bevel flat to the surface of the fine stone. All diamond stones should be misted lightly with water from a spray bottle. Add just enough water (10 drops or so) to lubricate your cut and carry away the metal particles (which some call "swarf.") My best advice here is to make long fluid strokes with the bevel of the chisel, pressing all water out from underneath the bevel during your strokes. Look closely at the cutting edge and you will see water scooting like a miniature wave on the stone's surface. When you see this, you're on your way to a seriously sharp edge. Hone the edge to remove the fine wire-like burr by using fine hard Arkansas oil stones or the extra fine diamond stone. I like to hone by pulling the chisel toward me rather than pushing it away from me. Once the burr is gone the chisel will be razor sharp. PW |