Popular Woodworking 2001-02 № 120, страница 38

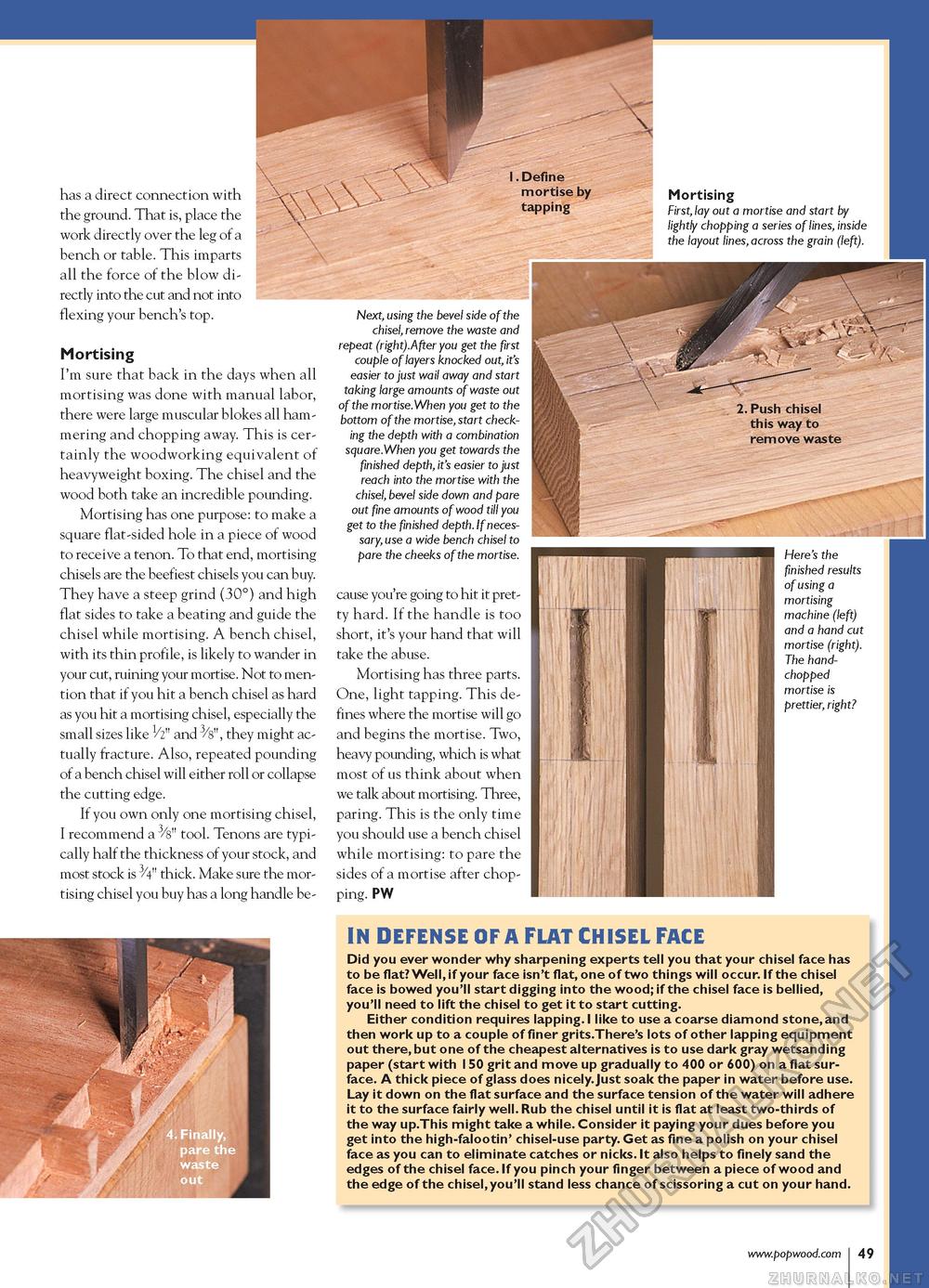

has a direct connection with the ground. That is, place the work directly over the leg of a bench or table. This imparts all the force of the blow directly into the cut and not into flexing your bench's top. Mortising I'm sure that back in the days when all mortising was done with manual labor, there were large muscular blokes all hammering and chopping away. This is certainly the woodworking equivalent of heavyweight boxing. The chisel and the wood both take an incredible pounding. Mortising has one purpose: to make a square flat-sided hole in a piece of wood to receive a tenon. To that end, mortising chisels are the beefiest chisels you can buy. They have a steep grind (30°) and high flat sides to take a beating and guide the chisel while mortising. A bench chisel, with its thin profile, is likely to wander in your cut, ruining your mortise. Not to mention that if you hit a bench chisel as hard as you hit a mortising chisel, especially the small sizes like 1/2" and 3/sn, they might actually fracture. Also, repeated pounding of a bench chisel will either roll or collapse the cutting edge. If you own only one mortising chisel, I recommend a 3/8" tool. Tenons are typically half the thickness of your stock, and most stock is ^V" thick. Make sure the mortising chisel you buy has a long handle be- 1. Define mortise by tapping Mortising First, lay out a mortise and start by lightly chopping a series of lines, inside the layout lines,across the grain (left). Next, using the bevel side of the chisel, remove the waste and repeat (right).After you get the first couple of layers knocked out, it's easier to just wail away and start taking large amounts of waste out of the mortise.When you get to the bottom of the mortise, start checking the depth with a combination square.When you get towards the finished depth, it's easier to just reach into the mortise with the chisel, bevel side down and pare out fine amounts of wood till you get to the finished depth. If necessary, use a wide bench chisel to pare the cheeks of the mortise. cause you're going to hit it pretty hard. If the handle is too short, it's your hand that will take the abuse. Mortising has three parts. One, light tapping. This defines where the mortise will go and begins the mortise. Two, heavy pounding, which is what most of us think about when we talk about mortising. Three, paring. This is the only time you should use a bench chisel while mortising: to pare the sides of a mortise after chopping. PW 2. Push chisel this way to remove waste Here's the finished results of using a mortising machine (left) and a hand cut mortise (right). The hand-chopped mortise is prettier, right? IN DEFENSE OF A FLAT CHISEL FACE Did you ever wonder why sharpening experts tell you that your chisel face has to be flat? Well, if your face isn't flat, one of two things will occur. If the chisel face is bowed you'll start digging into the wood; if the chisel face is bellied, you'll need to lift the chisel to get it to start cutting. Either condition requires lapping. I like to use a coarse diamond stone, and then work up to a couple of finer grits.There's lots of other lapping equipment out there, but one of the cheapest alternatives is to use dark gray wetsanding paper (start with 150 grit and move up gradually to 400 or 600) on a flat surface. A thick piece of glass does nicely.Just soak the paper in water before use. Lay it down on the flat surface and the surface tension of the water will adhere it to the surface fairly well. Rub the chisel until it is flat at least two-thirds of the way up.This might take a while. Consider it paying your dues before you get into the high-falootin' chisel-use party. Get as fine a polish on your chisel face as you can to eliminate catches or nicks. It also helps to finely sand the edges of the chisel face. If you pinch your finger between a piece of wood and the edge of the chisel,you'll stand less chance of scissoring a cut on your hand. |