Popular Woodworking 2001-08 № 123, страница 10

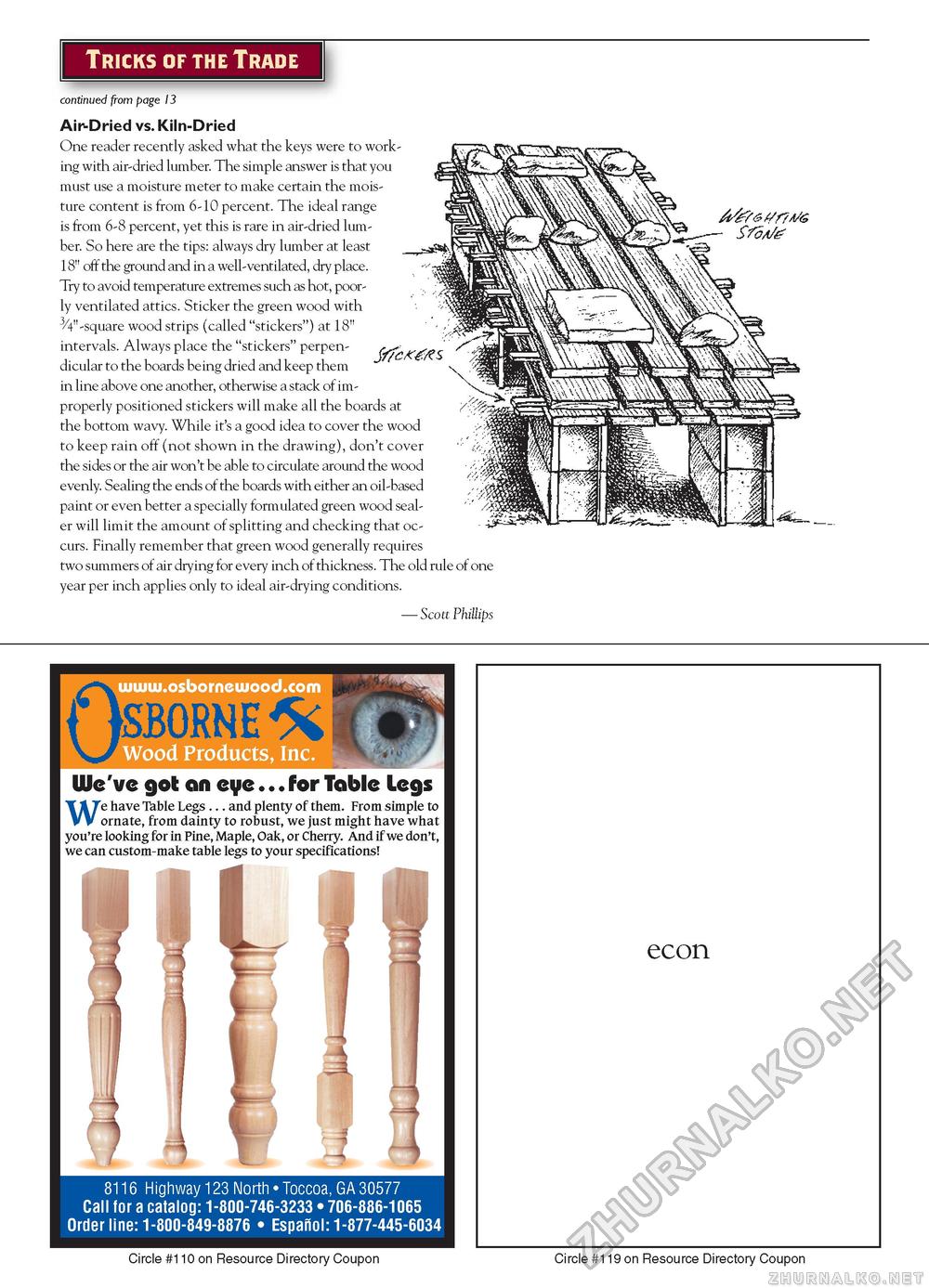

Tricks of the Tradecontinued from page 13 Air-Dried vs. Kiln-Dried One reader recently asked what the keys were to working with air-dried lumber. The simple answer is that you must use a moisture meter to make certain the moisture content is from 6-10 percent. The ideal range is from 6-8 percent, yet this is rare in air-dried lumber. So here are the tips: always dry lumber at least 18" off the ground and in a well-ventilated, dry place. Try to avoid temperature extremes such as hot, poorly ventilated attics. Sticker the green wood with 3/4"-square wood strips (called "stickers") at 18" intervals. Always place the "stickers" perpendicular to the boards being dried and keep them in line above one another, otherwise a stack of improperly positioned stickers will make all the boards at the bottom wavy. While it's a good idea to cover the wood to keep rain off (not shown in the drawing), don't cover the sides or the air won't be able to circulate around the wood evenly. Sealing the ends of the boards with either an oil-based paint or even better a specially formulated green wood sealer will limit the amount of splitting and checking that occurs. Finally remember that green wood generally requires two summers of air drying for every inch of thickness. The old rule of one year per inch applies only to ideal air-drying conditions. SfaA/e? — Scott Phillips a &BORNE^ Wood Products, Inc. We've got an eye...for Table Legs We have Table Legs . . . and plenty of them. From simple to ornate, from dainty to robust, we just might have what you're looking for in Pine, Maple, Oak, or Cherry. And if we don't, we can custom-make table legs to your specifications! econ8116 Highway 123 North • Toccoa, GA 30577 Call for a catalog: 1-800-746-3233 • 706-886-1065 Order line: 1-800-849-8876 • Espanol: 1-877-445-6034 Circle #110 on Resource Directory Coupon Circle #119 on Resource Directory Coupon |