Popular Woodworking 2002-02 № 126, страница 49

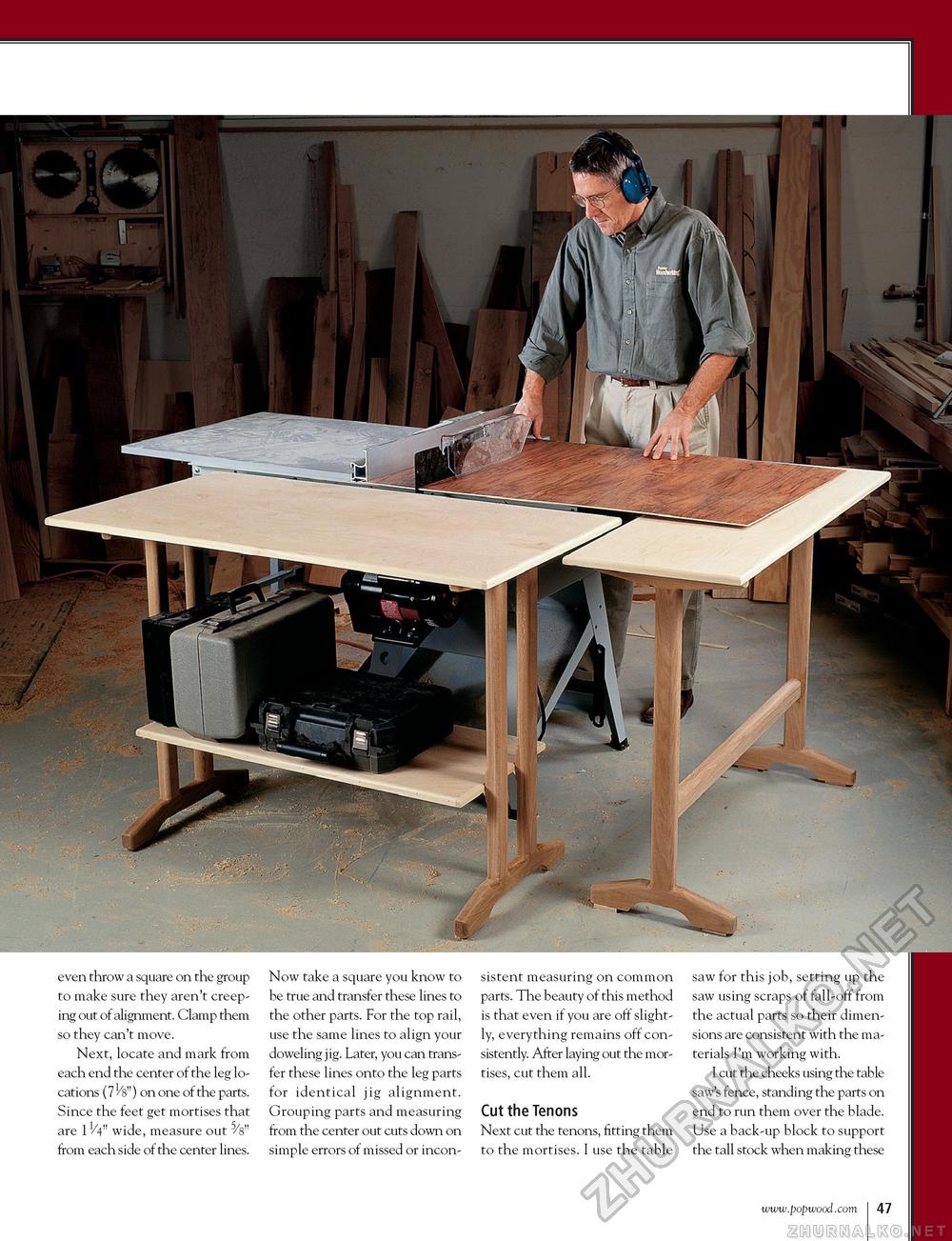

even throw a square on the group to make sure they aren't creeping out of alignment. Clamp them so they can't move. Next, locate and mark from each end the center of the leg locations (7Mi") on one of the parts. Since the feet get mortises that are 11/4" wide, measure out ^s" from each side of the center lines. Now take a square you know to be true and transfer these lines to the other parts. For the top rail, use the same lines to align your doweling jig. Later, you can transfer these lines onto the leg parts for identical jig alignment. Grouping parts and measuring from the center out cuts down on simple errors of missed or incon sistent measuring on common parts. The beauty of this method is that even if you are off slightly, everything remains off consistently. After laying out the mortises, cut them all. Cut the Tenons Next cut the tenons, fitting them to the mortises. I use the table saw for this job, setting up the saw using scraps of fall-off from the actual parts so their dimensions are consistent with the materials I'm working with. I cut the cheeks using the table saw's fence, standing the parts on end to run them over the blade. Use a back-up block to support the tall stock when making these www.popwood.com I 47 |