Popular Woodworking 2002-02 № 126, страница 85

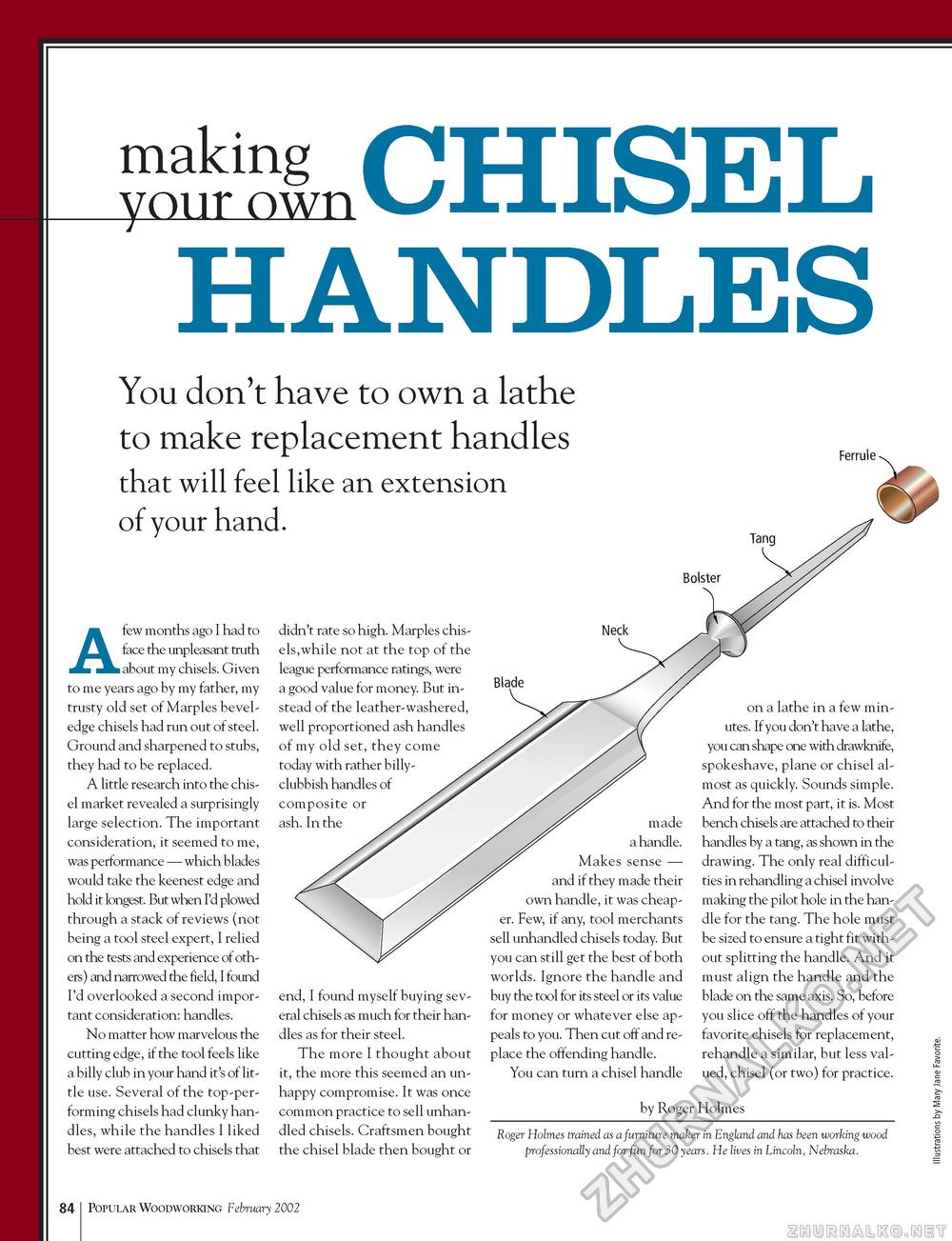

making your own CHISEL HANDLESYou don't have to own a lathe to make replacement handles that will feel like an extension of your hand. Ferrule A few months ago I had to face the unpleasant truth about my chisels. Given to me years ago by my father, my trusty old set of Marples bevel-edge chisels had run out of steel. Ground and sharpened to stubs, they had to be replaced. A little research into the chisel market revealed a surprisingly large selection. The important consideration, it seemed to me, was performance — which blades would take the keenest edge and hold it longest. But when I'd plowed through a stack of reviews (not being a tool steel expert, I relied on the tests and experience of others) and narrowed the field, I found I'd overlooked a second important consideration: handles. No matter how marvelous the cutting edge, if the tool feels like a billy club in your hand it's of little use. Several of the top-performing chisels had clunky handles, while the handles I liked best were attached to chisels that didn't rate so high. Marples chis-els,while not at the top of the league performance ratings, were a good value for money. But instead of the leather-washered, well proportioned ash handles of my old set, they come today with rather billy-clubbish handles of composite or ash. In the end, I found myself buying several chisels as much for their handles as for their steel. The more I thought about it, the more this seemed an unhappy compromise. It was once common practice to sell unhan-dled chisels. Craftsmen bought the chisel blade then bought or made a handle. Makes sense — and if they made their own handle, it was cheaper. Few, if any, tool merchants sell unhandled chisels today. But you can still get the best of both worlds. Ignore the handle and buy the tool for its steel or its value for money or whatever else appeals to you. Then cut off and replace the offending handle. You can turn a chisel handle on a lathe in a few minutes. If you don't have a lathe, you can shape one with drawknife, spokeshave, plane or chisel almost as quickly. Sounds simple. And for the most part, it is. Most bench chisels are attached to their handles by a tang, as shown in the drawing. The only real difficulties in rehandling a chisel involve making the pilot hole in the handle for the tang. The hole must be sized to ensure a tight fit without splitting the handle. And it must align the handle and the blade on the same axis. So, before you slice off the handles of your favorite chisels for replacement, rehandle a similar, but less valued, chisel (or two) for practice. by Roger Holmes Roger Holmes trained as a furniture maker in England and has been working wood professionally and for fun for 30 years. He lives in Lincoln, Nebraska. 84 |