Popular Woodworking 2002-02 № 126, страница 88

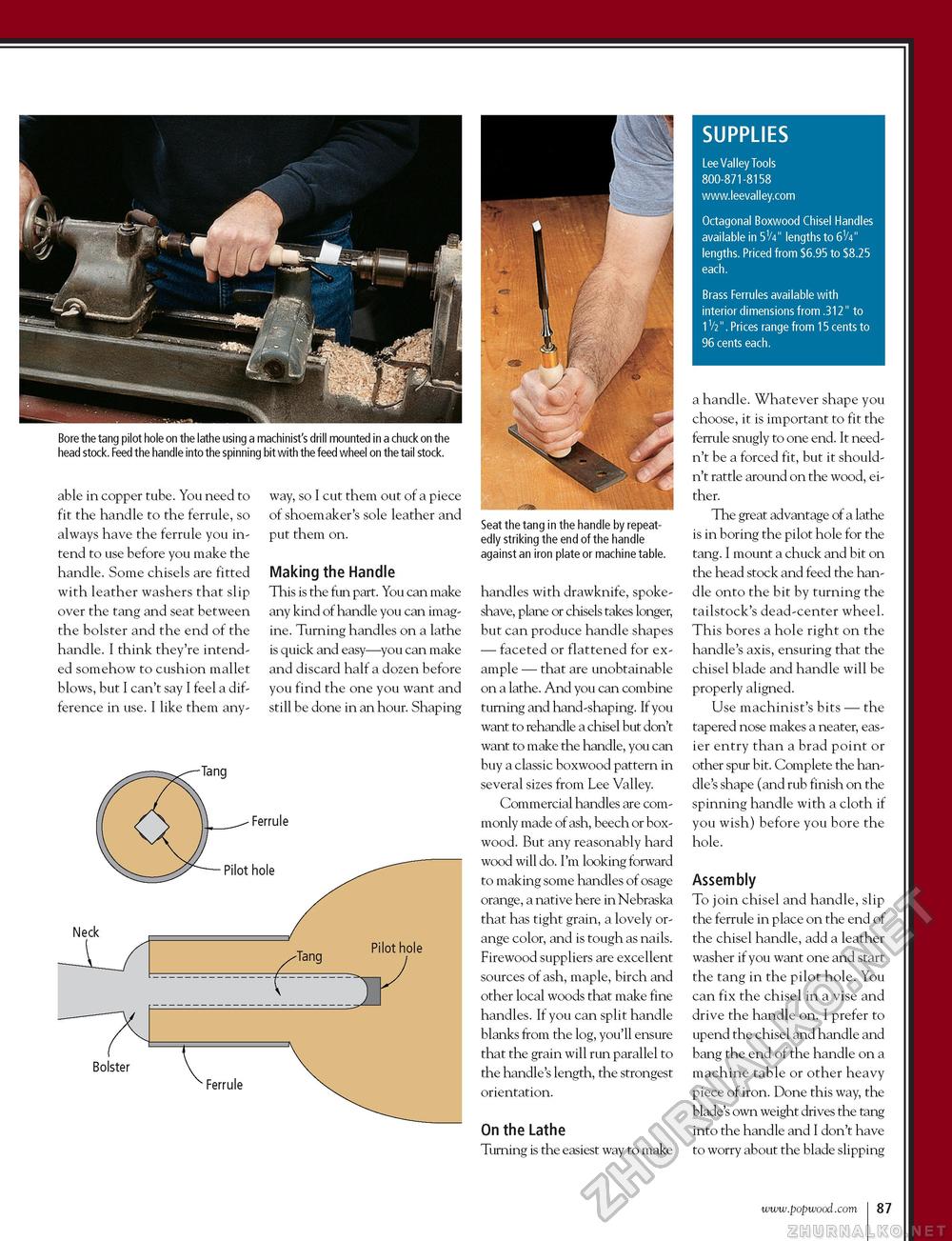

SUPPLIES Lee Valley Tools 800-871-8158 www.leevalley.com Octagonal Boxwood Chisel Handles available in 5V4" lengths to 6V4" lengths. Priced from $6.95 to $8.25 each. Brass Ferrules available with interior dimensions from .312" to 1V2". Prices range from 15 cents to 96 cents each. Bore the tang pilot hole on the lathe using a machinist's drill mounted in a chuck on the head stock. Feed the handle into the spinning bit with the feed wheel on the tail stock. able in copper tube. You need to fit the handle to the ferrule, so always have the ferrule you intend to use before you make the handle. Some chisels are fitted with leather washers that slip over the tang and seat between the bolster and the end of the handle. I think they're intended somehow to cushion mallet blows, but I can't say I feel a difference in use. I like them any way, so I cut them out of a piece of shoemaker's sole leather and put them on. Making the Handle This is the fun part. You can make any kind of handle you can imagine. Turning handles on a lathe is quick and easy—you can make and discard half a dozen before you find the one you want and still be done in an hour. Shaping Seat the tang in the handle by repeatedly striking the end of the handle against an iron plate or machine table. handles with drawknife, spoke-shave, plane or chisels takes longer, but can produce handle shapes — faceted or flattened for example — that are unobtainable on a lathe. And you can combine turning and hand-shaping. If you want to rehandle a chisel but don't want to make the handle, you can buy a classic boxwood pattern in several sizes from Lee Valley. Commercial handles are commonly made of ash, beech or boxwood. But any reasonably hard wood will do. I'm looking forward to making some handles of osage orange, a native here in Nebraska that has tight grain, a lovely orange color, and is tough as nails. Firewood suppliers are excellent sources of ash, maple, birch and other local woods that make fine handles. If you can split handle blanks from the log, you'll ensure that the grain will run parallel to the handle's length, the strongest orientation. On the Lathe Turning is the easiest way to make a handle. Whatever shape you choose, it is important to fit the ferrule snugly to one end. It needn't be a forced fit, but it shouldn't rattle around on the wood, either. The great advantage of a lathe is in boring the pilot hole for the tang. I mount a chuck and bit on the head stock and feed the handle onto the bit by turning the tailstock's dead-center wheel. This bores a hole right on the handle's axis, ensuring that the chisel blade and handle will be properly aligned. Use machinist's bits — the tapered nose makes a neater, easier entry than a brad point or other spur bit. Complete the handle's shape (and rub finish on the spinning handle with a cloth if you wish) before you bore the hole. Assembly To join chisel and handle, slip the ferrule in place on the end of the chisel handle, add a leather washer if you want one and start the tang in the pilot hole. You can fix the chisel in a vise and drive the handle on. I prefer to upend the chisel and handle and bang the end of the handle on a machine table or other heavy piece of iron. Done this way, the blade's own weight drives the tang into the handle and I don't have to worry about the blade slipping 87 |