Popular Woodworking 2002-10 № 130, страница 50

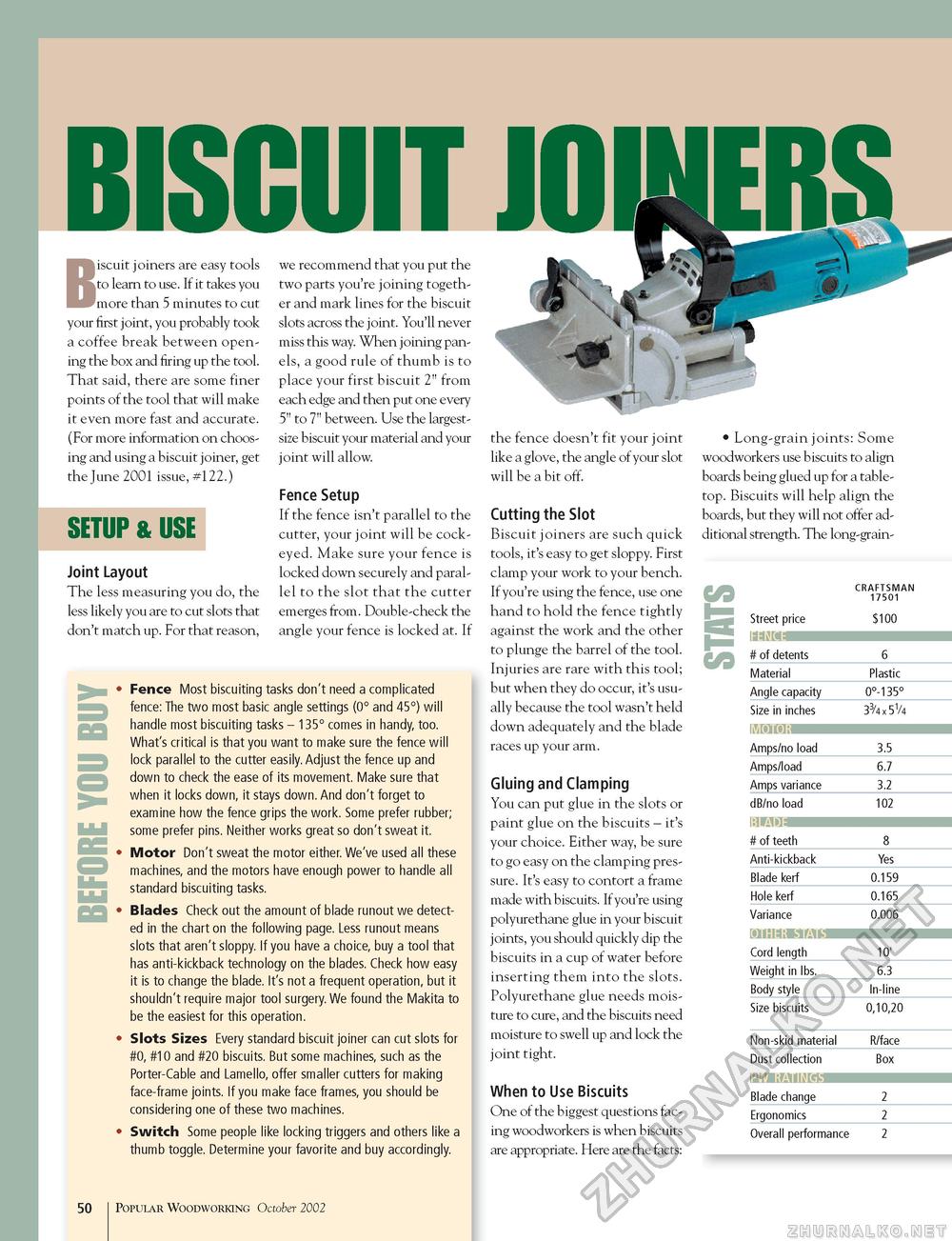

BISCUIT 101 Biscuit joiners are easy tools to learn to use. If it takes you more than 5 minutes to cut your first joint, you probably took a coffee break between opening the box and firing up the tool. That said, there are some finer points of the tool that will make it even more fast and accurate. (For more information on choosing and using a biscuit joiner, get the June 2001 issue, #122.) SETUP & USE Joint Layout The less measuring you do, the less likely you are to cut slots that don't match up. For that reason, we recommend that you put the two parts you're joining together and mark lines for the biscuit slots across the joint. You'll never miss this way. When joining panels, a good rule of thumb is to place your first biscuit 2" from each edge and then put one every 5" to 7" between. Use the largest-size biscuit your material and your joint will allow. Fence Setup If the fence isn't parallel to the cutter, your joint will be cockeyed. Make sure your fence is locked down securely and parallel to the slot that the cutter emerges from. Double-check the angle your fence is locked at. If Fence Most biscuiting tasks don't need a complicated fence: The two most basic angle settings (0° and 45°) will handle most biscuiting tasks - 135° comes in handy, too. What's critical is that you want to make sure the fence will lock parallel to the cutter easily. Adjust the fence up and down to check the ease of its movement. Make sure that when it locks down, it stays down. And don't forget to examine how the fence grips the work. Some prefer rubber; some prefer pins. Neither works great so don't sweat it. Motor Don't sweat the motor either. We've used all these machines, and the motors have enough power to handle all standard biscuiting tasks. Blades Check out the amount of blade runout we detected in the chart on the following page. Less runout means slots that aren't sloppy. If you have a choice, buy a tool that has anti-kickback technology on the blades. Check how easy it is to change the blade. It's not a frequent operation, but it shouldn't require major tool surgery. We found the Makita to be the easiest for this operation. Slots Sizes Every standard biscuit joiner can cut slots for #0, #10 and #20 biscuits. But some machines, such as the Porter-Cable and Lamello, offer smaller cutters for making face-frame joints. If you make face frames, you should be considering one of these two machines. Switch Some people like locking triggers and others like a thumb toggle. Determine your favorite and buy accordingly. the fence doesn't fit your joint like a glove, the angle of your slot will be a bit off. Cutting the Slot Biscuit joiners are such quick tools, it's easy to get sloppy. First clamp your work to your bench. If you're using the fence, use one hand to hold the fence tightly against the work and the other to plunge the barrel of the tool. Injuries are rare with this tool; but when they do occur, it's usually because the tool wasn't held down adequately and the blade races up your arm. Gluing and Clamping You can put glue in the slots or paint glue on the biscuits - it's your choice. Either way, be sure to go easy on the clamping pressure. It's easy to contort a frame made with biscuits. If you're using polyurethane glue in your biscuit joints, you should quickly dip the biscuits in a cup of water before inserting them into the slots. Polyurethane glue needs moisture to cure, and the biscuits need moisture to swell up and lock the joint tight. When to Use Biscuits One of the biggest questions facing woodworkers is when biscuits are appropriate. Here are the facts: • Long-grain joints: Some woodworkers use biscuits to align boards being glued up for a table-top. Biscuits will help align the boards, but they will not offer additional strength. The long-grain- CRAFTSMAN 17501 CRAFTSMAN 17501

50 Popular Woodworking October 2002 |