Popular Woodworking 2002-12 № 131, страница 59

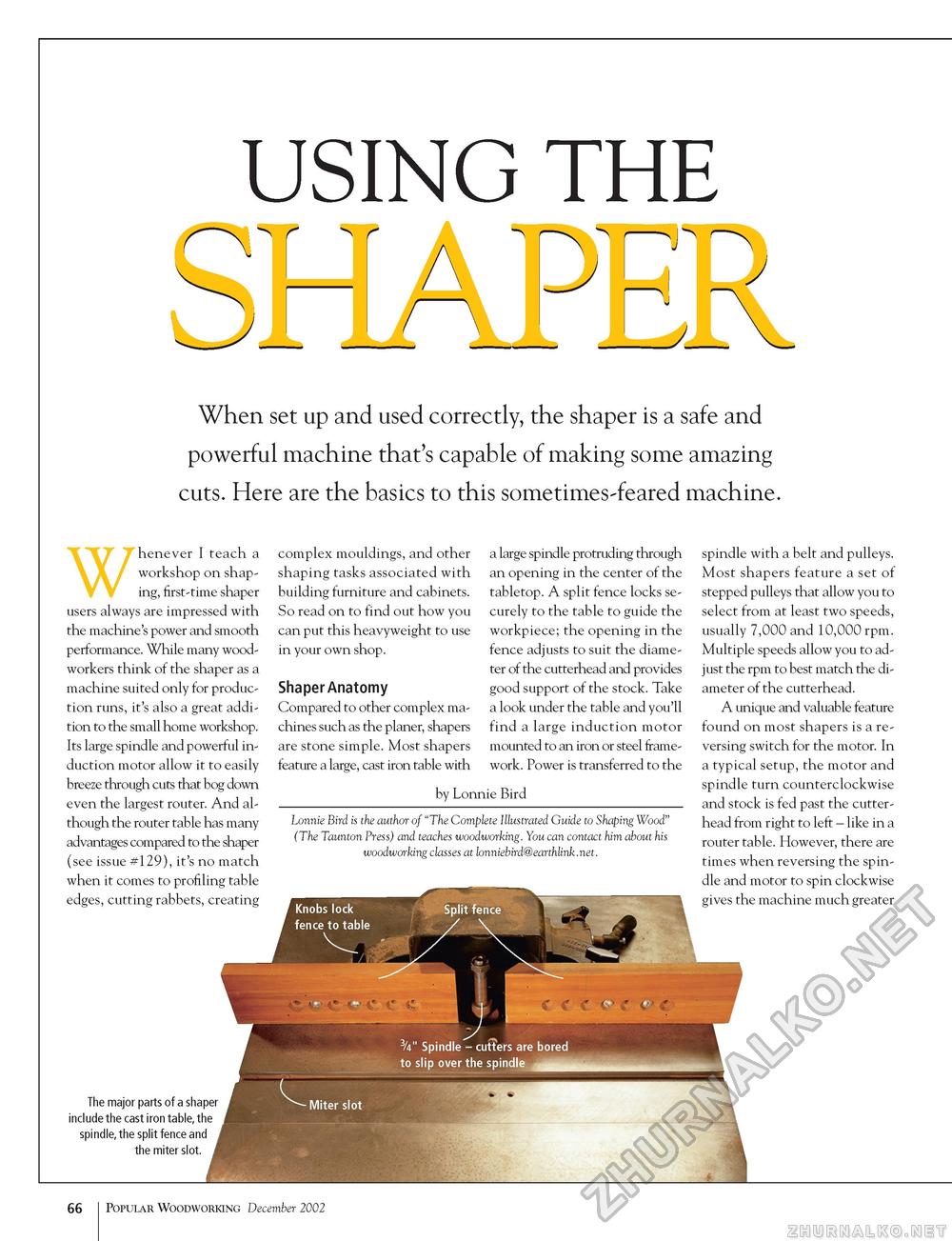

USING THE When set up and used correctly, the shaper is a safe and powerful machine that's capable of making some amazing cuts. Here are the basics to this sometimes-feared machine. Whenever I teach a workshop on shaping, first-time shaper users always are impressed with the machine's power and smooth performance. While many woodworkers think of the shaper as a machine suited only for production runs, it's also a great addition to the small home workshop. Its large spindle and powerful induction motor allow it to easily breeze through cuts that bog down even the largest router. And although the router table has many advantages compared to the shaper (see issue #129), it's no match when it comes to profiling table edges, cutting rabbets, creating The major parts of a shaper include the cast iron table, the spindle, the split fence and the miter slot. complex mouldings, and other shaping tasks associated with building furniture and cabinets. So read on to find out how you can put this heavyweight to use in your own shop. Shaper Anatomy Compared to other complex machines such as the planer, shapers are stone simple. Most shapers feature a large, cast iron table with a large spindle protruding through an opening in the center of the tabletop. A split fence locks securely to the table to guide the workpiece; the opening in the fence adjusts to suit the diameter of the cutterhead and provides good support of the stock. Take a look under the table and you'll find a large induction motor mounted to an iron or steel framework. Power is transferred to the by Lonnie Bird Lonnie Bird is the author of"The Complete Illustrated Guide to Shaping Wood" (The Taunton Press) and teaches woodworking. You can contact him about his woodworking classes at lonniebird@earthlink.net. spindle with a belt and pulleys. Most shapers feature a set of stepped pulleys that allow you to select from at least two speeds, usually 7,000 and 10,000 rpm. Multiple speeds allow you to adjust the rpm to best match the diameter of the cutterhead. A unique and valuable feature found on most shapers is a reversing switch for the motor. In a typical setup, the motor and spindle turn counterclockwise and stock is fed past the cutter-head from right to left - like in a router table. However, there are times when reversing the spindle and motor to spin clockwise gives the machine much greater 66 Popular Woodworking December 2002 |