Popular Woodworking 2003-02 № 132, страница 42

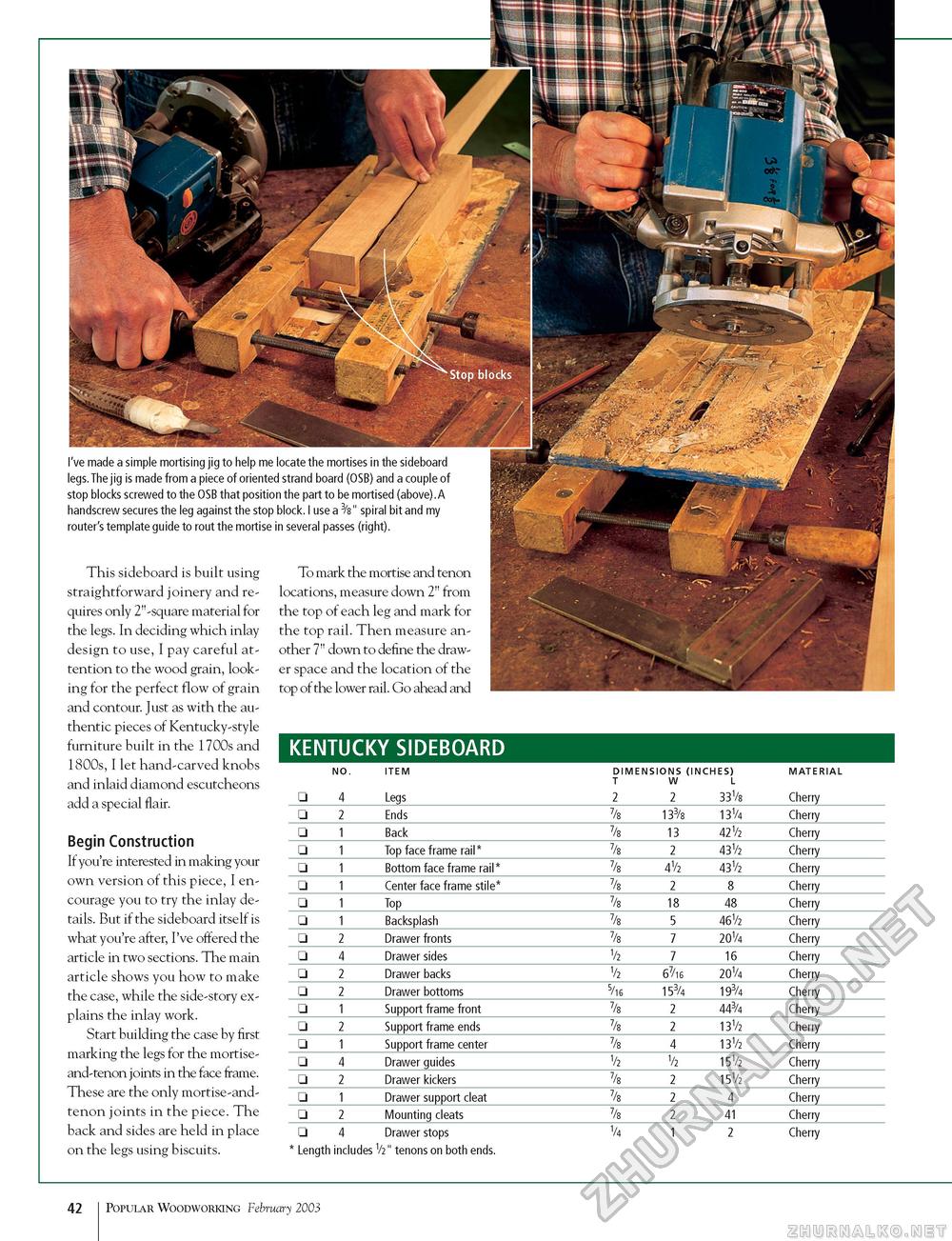

I've made a simple mortising jig to help me locate the mortises in the sideboard legs.The jig is made from a piece of oriented strand board (OSB) and a couple of stop blocks screwed to the OSB that position the part to be mortised (above).A handscrew secures the leg against the stop block. I use a 3/b" spiral bit and my router's template guide to rout the mortise in several passes (right). This sideboard is built using straightforward joinery and requires only 2"-square material for the legs. In deciding which inlay design to use, I pay careful attention to the wood grain, looking for the perfect flow of grain and contour. Just as with the authentic pieces of Kentucky-style furniture built in the 1700s and 1800s, I let hand-carved knobs and inlaid diamond escutcheons add a special flair. Begin Construction If you're interested in making your own version of this piece, I encourage you to try the inlay details. But if the sideboard itself is what you're after, I've offered the article in two sections. The main article shows you how to make the case, while the side-story explains the inlay work. Start building the case by first marking the legs for the mortise-and-tenon joints in the face frame. These are the only mortise-and-tenon joints in the piece. The back and sides are held in place on the legs using biscuits. To mark the mortise and tenon locations, measure down 2" from the top of each leg and mark for the top rail. Then measure another 7" down to define the drawer space and the location of the top of the lower rail. Go ahead and KENTUCKY SIDEBOARD

* Length includes V2" tenons on both ends. * Length includes V2" tenons on both ends. 42 Popular Woodworking February 2003 |

|||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||||