Popular Woodworking 2003-10 № 136, страница 38

Power-tool Joinery Splined JointsLearn how to make one of the best tools to align your edges and joints -the spline. If you want to increase a joint's strength and simplify its assembly, I suggest adding a spline. It's an enhancement that is often advocated for edge joints, but it is most appropriate in a miter joint. The process is pretty simple: You cut the grooves in the mating surfaces of the joint and as you assemble the joint you insert a spline, which bridges the seam and links the two pieces. The drawings below show the most common varieties. In the through spline, the grooves are cut from edge to edge and the ends are visible in the assembled joint. In the blind spline, the grooves end short of ei-

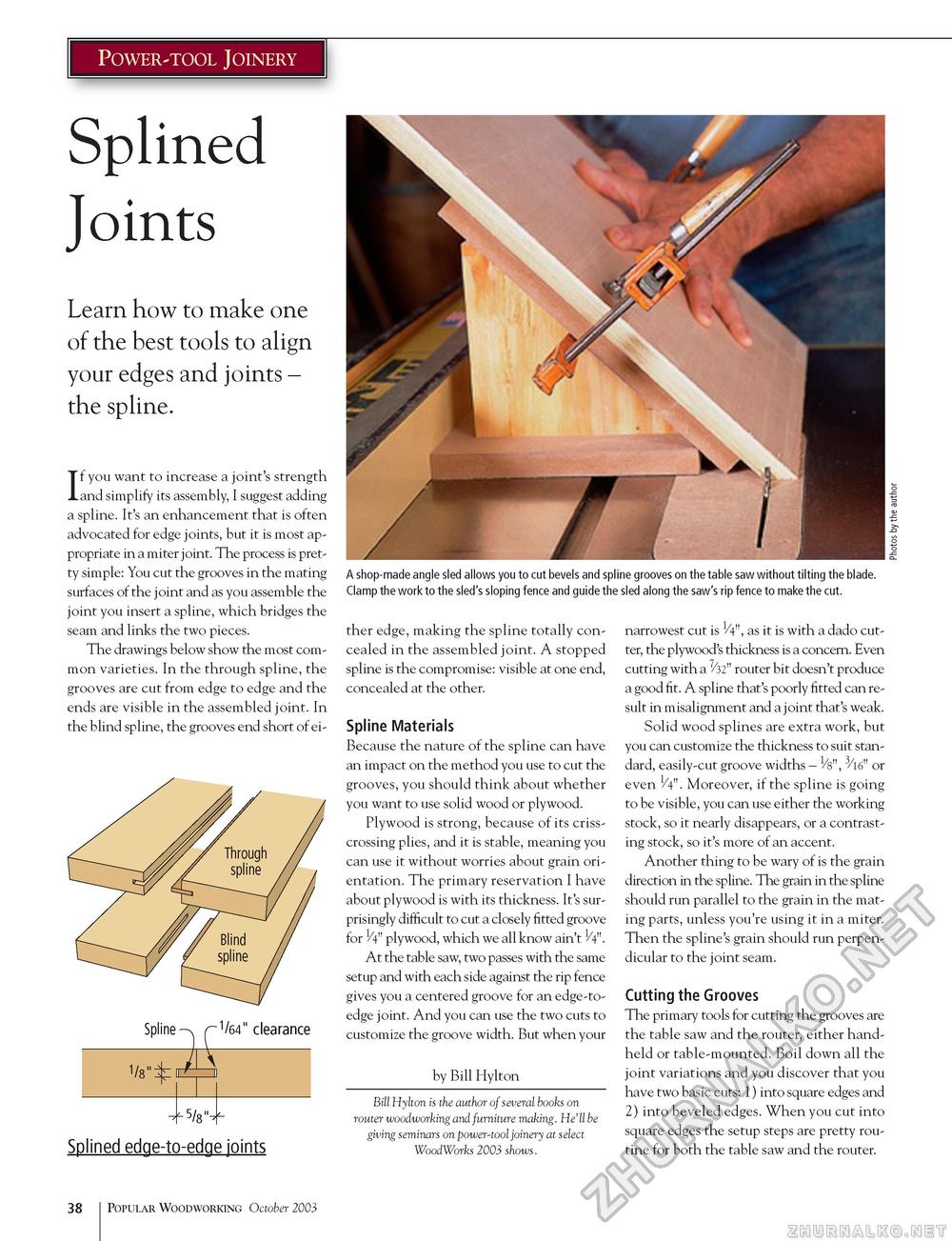

A shop-made angle sled allows you to cut bevels and spline grooves on the table saw without tilting the blade. Clamp the work to the sled's sloping fence and guide the sled along the saw's rip fence to make the cut. Splined edge-to-edge joints ther edge, making the spline totally concealed in the assembled joint. A stopped spline is the compromise: visible at one end, concealed at the other. Spline Materials Because the nature of the spline can have an impact on the method you use to cut the grooves, you should think about whether you want to use solid wood or plywood. Plywood is strong, because of its crisscrossing plies, and it is stable, meaning you can use it without worries about grain orientation. The primary reservation I have about plywood is with its thickness. It's surprisingly difficult to cut a closely fitted groove for H" plywood, which we all know ain't V4". At the table saw, two passes with the same setup and with each side against the rip fence gives you a centered groove for an edge-to-edge joint. And you can use the two cuts to customize the groove width. But when your by Bill Hylton Bill Hylton is the author of several books on router woodworking and furniture making. He'll be giving seminars on power-tool joinery at select WoodWorks 2003 shows. narrowest cut is 1/4", as it is with a dado cutter, the plywood's thickness is a concern. Even cutting with a 732" router bit doesn't produce a good fit. A spline that's poorly fitted can result in misalignment and a joint that's weak. Solid wood splines are extra work, but you can customize the thickness to suit standard, easily-cut groove widths - or even 1/4". Moreover, if the spline is going to be visible, you can use either the working stock, so it nearly disappears, or a contrasting stock, so it's more of an accent. Another thing to be wary of is the grain direction in the spline. The grain in the spline should run parallel to the grain in the mating parts, unless you're using it in a miter. Then the spline's grain should run perpendicular to the joint seam. Cutting the Grooves The primary tools for cutting the grooves are the table saw and the router, either handheld or table-mounted. Boil down all the joint variations and you discover that you have two basic cuts: 1) into square edges and 2) into beveled edges. When you cut into square edges the setup steps are pretty routine for both the table saw and the router. 38 Popular Woodworking October 2003 |

|||||||||||||||