Popular Woodworking 2003-11 № 137, страница 42

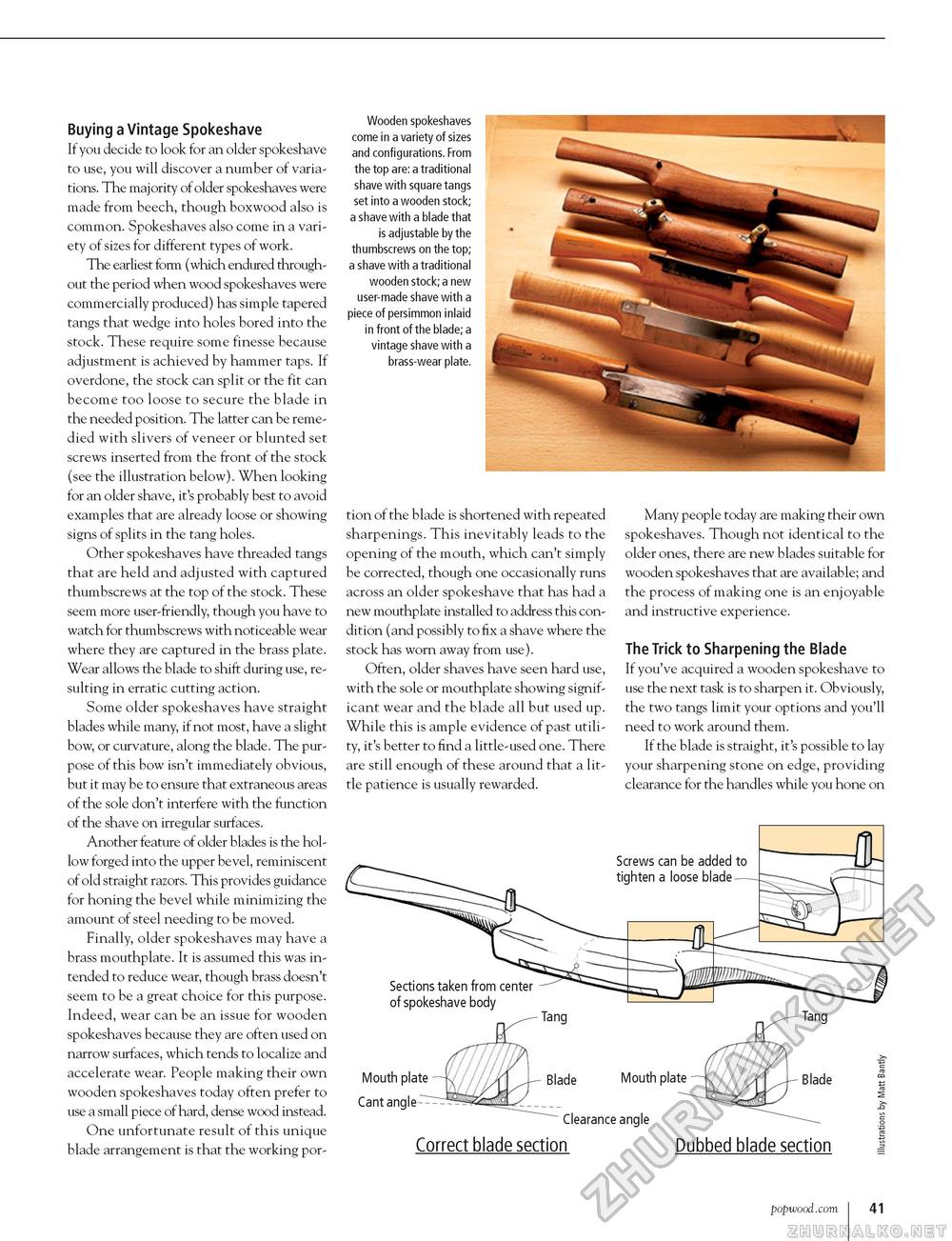

Wooden spokeshaves come in a variety of sizes and configurations. From the top are: a traditional shave with square tangs set into a wooden stock; a shave with a blade that is adjustable by the thumbscrews on the top; a shave with a traditional wooden stock; a new user-made shave with a piece of persimmon inlaid in front of the blade; a vintage shave with a brass-wear plate. Buying a Vintage Spokeshave If you decide to look for an older spokeshave to use, you will discover a number of variations. The majority of older spokeshaves were made from beech, though boxwood also is common. Spokeshaves also come in a variety of sizes for different types of work. The earliest form (which endured throughout the period when wood spokeshaves were commercially produced) has simple tapered tangs that wedge into holes bored into the stock. These require some finesse because adjustment is achieved by hammer taps. If overdone, the stock can split or the fit can become too loose to secure the blade in the needed position. The latter can be remedied with slivers of veneer or blunted set screws inserted from the front of the stock (see the illustration below). When looking for an older shave, it's probably best to avoid examples that are already loose or showing signs of splits in the tang holes. Other spokeshaves have threaded tangs that are held and adjusted with captured thumbscrews at the top of the stock. These seem more user-friendly, though you have to watch for thumbscrews with noticeable wear where they are captured in the brass plate. Wear allows the blade to shift during use, resulting in erratic cutting action. Some older spokeshaves have straight blades while many, if not most, have a slight bow, or curvature, along the blade. The purpose of this bow isn't immediately obvious, but it may be to ensure that extraneous areas of the sole don't interfere with the function of the shave on irregular surfaces. Another feature of older blades is the hollow forged into the upper bevel, reminiscent of old straight razors. This provides guidance for honing the bevel while minimizing the amount of steel needing to be moved. Finally, older spokeshaves may have a brass mouthplate. It is assumed this was intended to reduce wear, though brass doesn't seem to be a great choice for this purpose. Indeed, wear can be an issue for wooden spokeshaves because they are often used on narrow surfaces, which tends to localize and accelerate wear. People making their own wooden spokeshaves today often prefer to use a small piece of hard, dense wood instead. One unfortunate result of this unique blade arrangement is that the working por- tion of the blade is shortened with repeated sharpenings. This inevitably leads to the opening of the mouth, which can't simply be corrected, though one occasionally runs across an older spokeshave that has had a new mouthplate installed to address this condition (and possibly to fix a shave where the stock has worn away from use). Often, older shaves have seen hard use, with the sole or mouthplate showing significant wear and the blade all but used up. While this is ample evidence of past utility, it's better to find a little-used one. There are still enough of these around that a little patience is usually rewarded. Many people today are making their own spokeshaves. Though not identical to the older ones, there are new blades suitable for wooden spokeshaves that are available; and the process of making one is an enjoyable and instructive experience. The Trick to Sharpening the Blade If you've acquired a wooden spokeshave to use the next task is to sharpen it. Obviously, the two tangs limit your options and you'll need to work around them. If the blade is straight, it's possible to lay your sharpening stone on edge, providing clearance for the handles while you hone on Screws can be added to tighten a loose blade — Sections taken from center of spokeshave body Mouth plate Cant angle Clearance angle Correct blade section Dubbed blade section popwood.com 41 |