Popular Woodworking 2003-11 № 137, страница 43

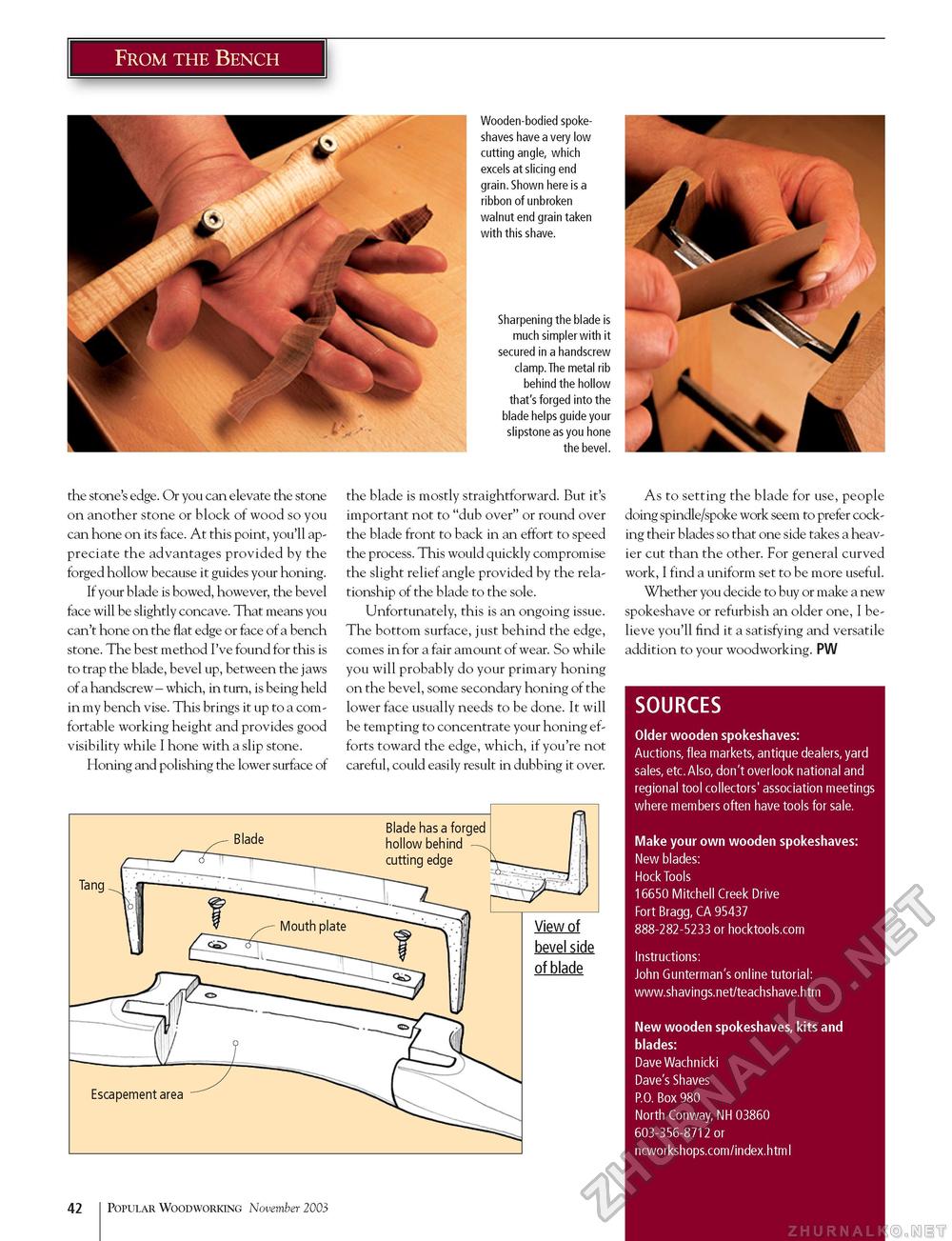

Wooden-bodied spoke-shaves have a very low cutting angle, which excels at slicing end grain. Shown here is a ribbon of unbroken walnut end grain taken with this shave. Sharpening the blade is much simpler with it secured in a handscrew clamp.The metal rib behind the hollow that's forged into the blade helps guide your slipstone as you hone the bevel. the stone's edge. Or you can elevate the stone on another stone or block of wood so you can hone on its face. At this point, you'll appreciate the advantages provided by the forged hollow because it guides your honing. If your blade is bowed, however, the bevel face will be slightly concave. That means you can't hone on the flat edge or face of a bench stone. The best method I've found for this is to trap the blade, bevel up, between the jaws of a handscrew - which, in turn, is being held in my bench vise. This brings it up to a comfortable working height and provides good visibility while I hone with a slip stone. Honing and polishing the lower surface of the blade is mostly straightforward. But it's important not to "dub over" or round over the blade front to back in an effort to speed the process. This would quickly compromise the slight relief angle provided by the relationship of the blade to the sole. Unfortunately, this is an ongoing issue. The bottom surface, just behind the edge, comes in for a fair amount of wear. So while you will probably do your primary honing on the bevel, some secondary honing of the lower face usually needs to be done. It will be tempting to concentrate your honing efforts toward the edge, which, if you're not careful, could easily result in dubbing it over. As to setting the blade for use, people doing spindle/spoke work seem to prefer cocking their blades so that one side takes a heavier cut than the other. For general curved work, I find a uniform set to be more useful. Whether you decide to buy or make a new spokeshave or refurbish an older one, I believe you'll find it a satisfying and versatile addition to your woodworking. PW SOURCES Older wooden spokeshaves: Auctions, flea markets, antique dealers, yard sales, etc. Also, don't overlook national and regional tool collectors' association meetings where members often have tools for sale. Make your own wooden spokeshaves: New blades: Hock Tools 16650 Mitchell Creek Drive Fort Bragg, CA 95437 888-282-5233 or hocktools.com Instructions: John Gunterman's online tutorial: www.shavings.net/teachshave.htm New wooden spokeshaves, kits and blades: Dave Wachnicki Dave's Shaves P.O. Box 980 North Conway, NH 03860 603-356-8712 or ncworkshops.com/index.html |

||||||||