Popular Woodworking 2004-02 № 139, страница 60

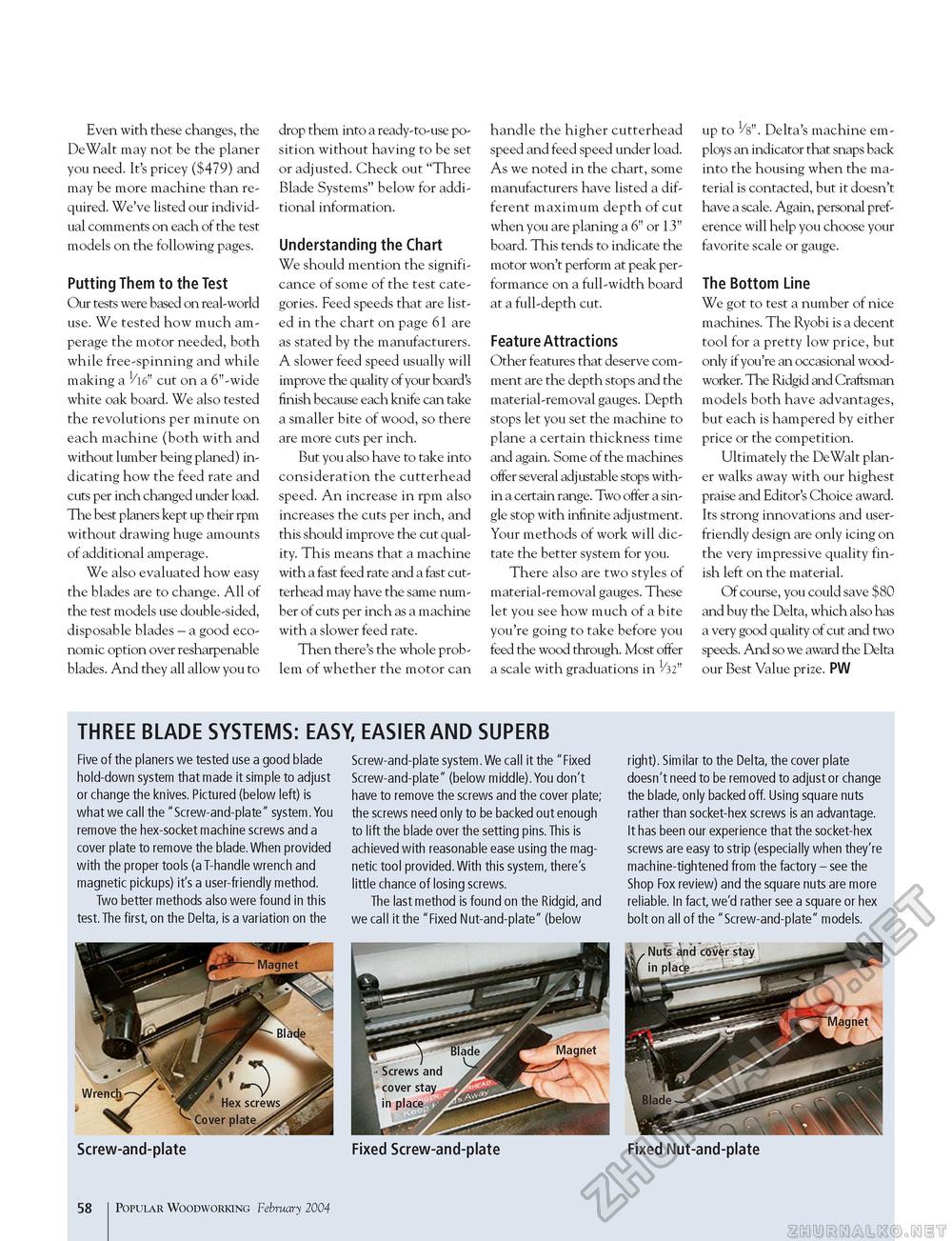

Even with these changes, the DeWalt may not be the planer you need. It's pricey ($479) and may be more machine than required. We've listed our individual comments on each of the test models on the following pages. Putting Them to the Test Our tests were based on real-world use. We tested how much amperage the motor needed, both while free-spinning and while making a 1/16" cut on a 6"-wide white oak board. We also tested the revolutions per minute on each machine (both with and without lumber being planed) indicating how the feed rate and cuts per inch changed under load. The best planers kept up their rpm without drawing huge amounts of additional amperage. We also evaluated how easy the blades are to change. All of the test models use double-sided, disposable blades - a good economic option over resharpenable blades. And they all allow you to drop them into a ready-to-use position without having to be set or adjusted. Check out "Three Blade Systems" below for additional information. Understanding the Chart We should mention the significance of some of the test categories. Feed speeds that are listed in the chart on page 61 are as stated by the manufacturers. A slower feed speed usually will improve the quality of your board's finish because each knife can take a smaller bite of wood, so there are more cuts per inch. But you also have to take into consideration the cutterhead speed. An increase in rpm also increases the cuts per inch, and this should improve the cut quality. This means that a machine with a fast feed rate and a fast cut-terhead may have the same number of cuts per inch as a machine with a slower feed rate. Then there's the whole problem of whether the motor can handle the higher cutterhead speed and feed speed under load. As we noted in the chart, some manufacturers have listed a different maximum depth of cut when you are planing a 6" or 13" board. This tends to indicate the motor won't perform at peak performance on a full-width board at a full-depth cut. Feature Attractions Other features that deserve comment are the depth stops and the material-removal gauges. Depth stops let you set the machine to plane a certain thickness time and again. Some of the machines offer several adjustable stops within a certain range. Two offer a single stop with infinite adjustment. Your methods of work will dictate the better system for you. There also are two styles of material-removal gauges. These let you see how much of a bite you're going to take before you feed the wood through. Most offer a scale with graduations in 1/32" up to 1/8". Delta's machine employs an indicator that snaps back into the housing when the material is contacted, but it doesn't have a scale. Again, personal preference will help you choose your favorite scale or gauge. The Bottom Line We got to test a number of nice machines. The Ryobi is a decent tool for a pretty low price, but only if you're an occasional woodworker. The Ridgid and Craftsman models both have advantages, but each is hampered by either price or the competition. Ultimately the DeWalt planer walks away with our highest praise and Editor's Choice award. Its strong innovations and user-friendly design are only icing on the very impressive quality finish left on the material. Of course, you could save $80 and buy the Delta, which also has a very good quality of cut and two speeds. And so we award the Delta our Best Value prize. PW THREE BLADE SYSTEMS: EASY, EASIER AND SUPERB Five of the planers we tested use a good blade hold-down system that made it simple to adjust or change the knives. Pictured (below left) is what we call the "Screw-and-plate" system.You remove the hex-socket machine screws and a cover plate to remove the blade.When provided with the proper tools (a T-handle wrench and magnetic pickups) it's a user-friendly method. Two better methods also were found in this test. The first, on the Delta, is a variation on the Screw-and-plate system.We call it the "Fixed Screw-and-plate" (below middle).You don't have to remove the screws and the cover plate; the screws need only to be backed out enough to lift the blade over the setting pins. This is achieved with reasonable ease using the magnetic tool provided.With this system, there's little chance of losing screws. The last method is found on the Ridgid, and we call it the "Fixed Nut-and-plate" (below right). Similar to the Delta, the cover plate doesn't need to be removed to adjust or change the blade, only backed off. Using square nuts rather than socket-hex screws is an advantage. It has been our experience that the socket-hex screws are easy to strip (especially when they're machine-tightened from the factory - see the Shop Fox review) and the square nuts are more reliable. In fact, we'd rather see a square or hex bolt on all of the "Screw-and-plate" models. Fixed Screw-and-plate Fixed Nut-and-plate 58 Popular Woodworking February 2004 |