Popular Woodworking 2004-02 № 139, страница 57

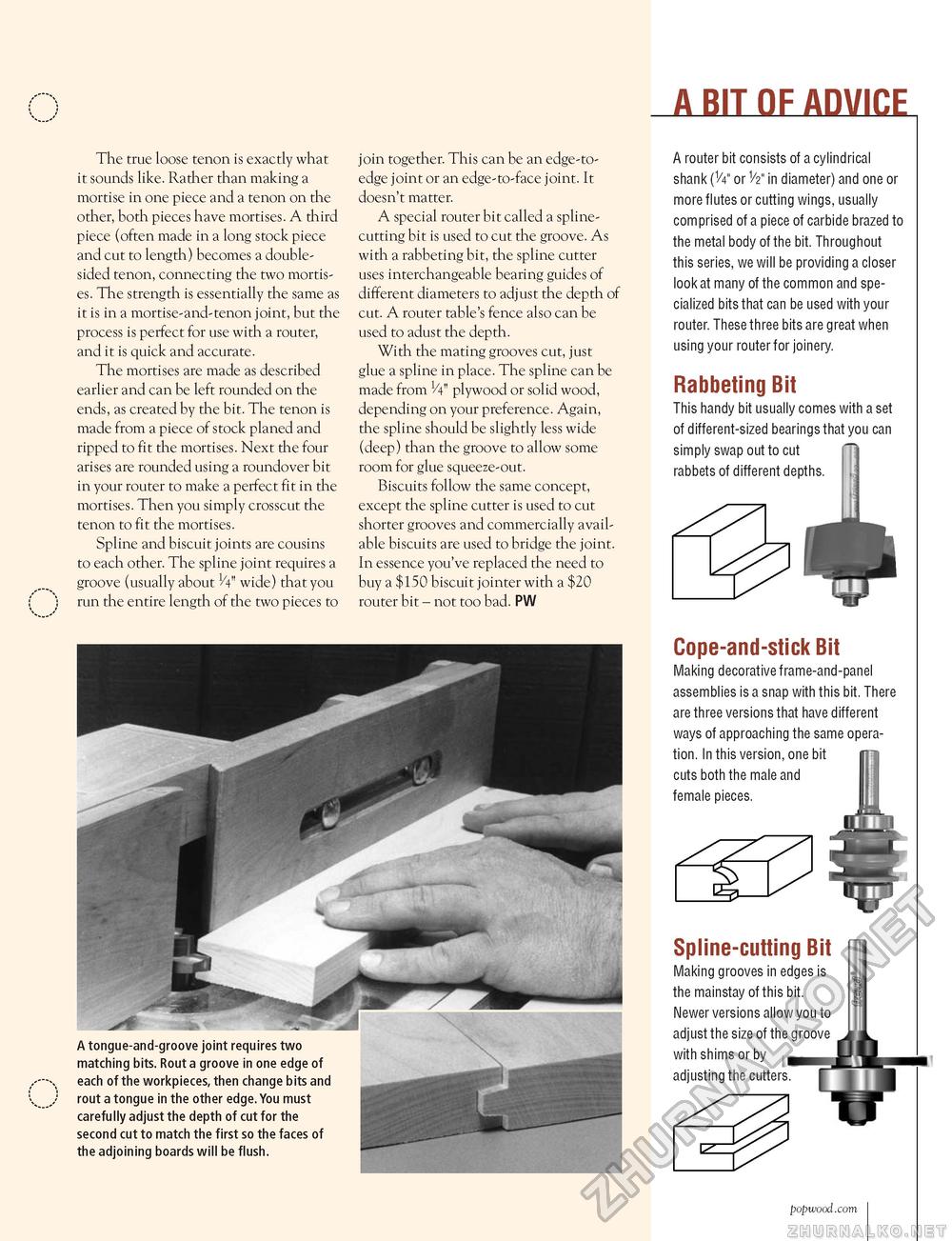

A BIT OF ADVICE The true loose tenon is exactly what it sounds like. Rather than making a mortise in one piece and a tenon on the other, both pieces have mortises. A third piece (often made in a long stock piece and cut to length) becomes a double-sided tenon, connecting the two mortises. The strength is essentially the same as it is in a mortise-and-tenon joint, but the process is perfect for use with a router, and it is quick and accurate. The mortises are made as described earlier and can be left rounded on the ends, as created by the bit. The tenon is made from a piece of stock planed and ripped to fit the mortises. Next the four arises are rounded using a roundover bit in your router to make a perfect fit in the mortises. Then you simply crosscut the tenon to fit the mortises. Spline and biscuit joints are cousins to each other. The spline joint requires a groove (usually about 1/4" wide) that you run the entire length of the two pieces to join together. This can be an edge-to-edge joint or an edge-to-face joint. It doesn't matter. A special router bit called a spline-cutting bit is used to cut the groove. As with a rabbeting bit, the spline cutter uses interchangeable bearing guides of different diameters to adjust the depth of cut. A router table's fence also can be used to adust the depth. With the mating grooves cut, just glue a spline in place. The spline can be made from 1/4n plywood or solid wood, depending on your preference. Again, the spline should be slightly less wide (deep) than the groove to allow some room for glue squeeze-out. Biscuits follow the same concept, except the spline cutter is used to cut shorter grooves and commercially available biscuits are used to bridge the joint. In essence you've replaced the need to buy a $150 biscuit jointer with a $20 router bit - not too bad. PW A router bit consists of a cylindrical shank (V4" or 1/2" in diameter) and one or more flutes or cutting wings, usually comprised of a piece of carbide brazed to the metal body of the bit. Throughout this series, we will be providing a closer look at many of the common and specialized bits that can be used with your router. These three bits are great when using your router for joinery. Rabbeting Bit This handy bit usually comes with a set of different-sized bearings that you can simply swap out to cut rabbets of different depths. A tongue-and-groove joint requires two matching bits. Rout a groove in one edge of each of the workpieces, then change bits and rout a tongue in the other edge. You must carefully adjust the depth of cut for the second cut to match the first so the faces of the adjoining boards will be flush. Cope-and-stick Bit Making decorative frame-and-panel assemblies is a snap with this bit. There are three versions that have different ways of approaching the same operation. In this version, one bit cuts both the male and female pieces. Spline-cutting Bit Making grooves in edges is the mainstay of this bit. Newer versions allow you to adjust the size of the groove with shims or by adjusting the cutters. popwood.com 57 |