Popular Woodworking 2004-02 № 139, страница 84

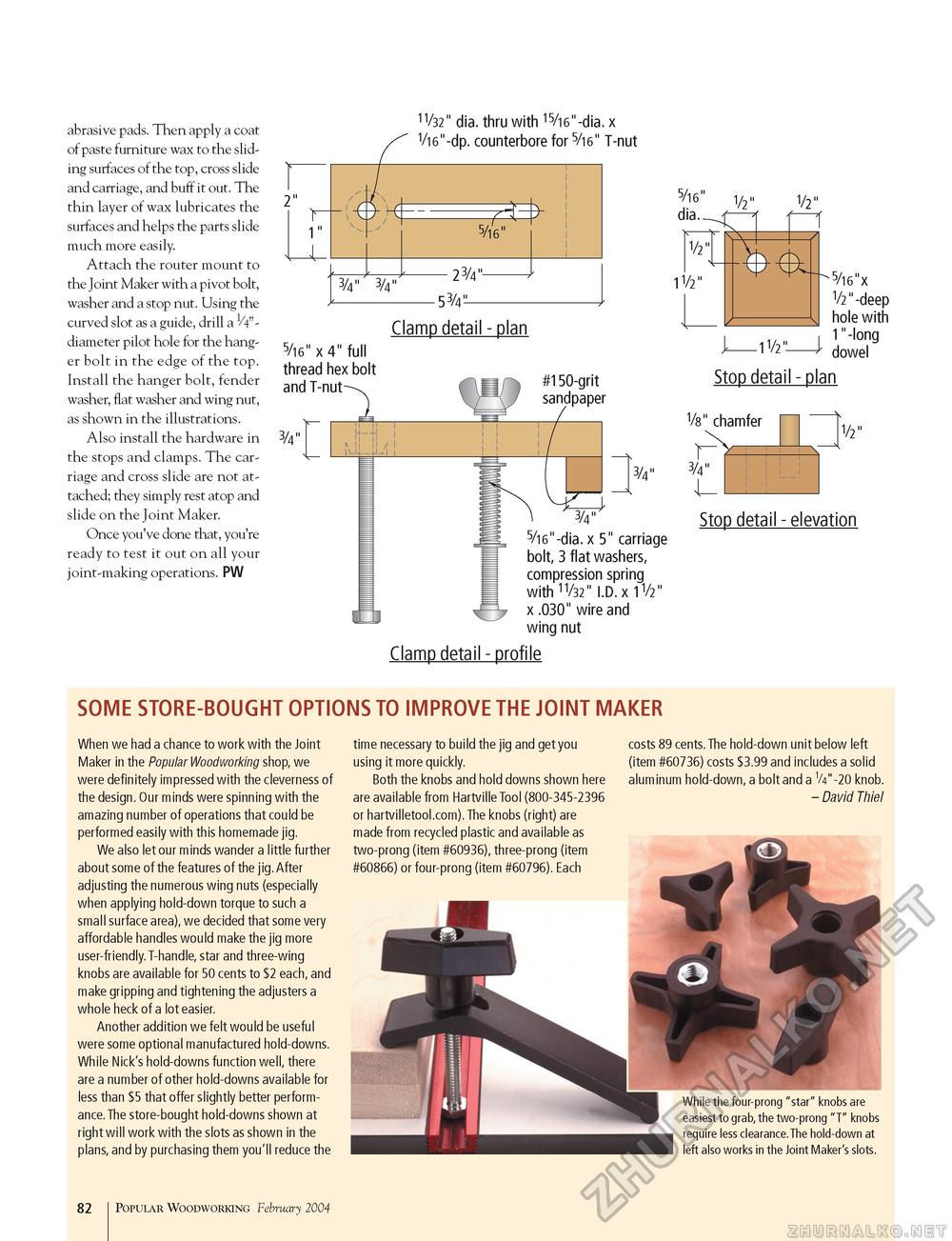

abrasive pads. Then apply a coat of paste furniture wax to the sliding surfaces of the top, cross slide and carriage, and buff it out. The thin layer of wax lubricates the surfaces and helps the parts slide much more easily. Attach the router mount to the Joint Maker with a pivot bolt, washer and a stop nut. Using the curved slot as a guide, drill a V4"-diameter pilot hole for the hanger bolt in the edge of the top. Install the hanger bolt, fender washer, flat washer and wing nut, as shown in the illustrations. Also install the hardware in the stops and clamps. The carriage and cross slide are not attached; they simply rest atop and slide on the Joint Maker. Once you've done that, you're ready to test it out on all your joint-making operations. PW 2" 11/32" dia. thru with 15/i6"-dia. x Vi6"-dp. counterbore for 5/i6" T-nut 5/i6" 23/4"- 53/4" 5/i6" dia. 1/2" 1^/2" vr vr 5/i6" x 4" full thread hex bolt and T-nut 3/4" Clamp detail - plan 5/i6"x V2"-deep hole with 1"-long dowel #150-grit sandpaper K I I /I I l-U-!—| Stop detail - plan V8" chamfer 3/4" 3/4" 5/i6"-dia. x 5" carriage bolt, 3 flat washers, compression spring with " I.D. x 1V2" x .030" wire and wing nut Clamp detail - profile 3/4" V2" Stop detail - elevation SOME STORE-BOUGHT OPTIONS TO IMPROVE THE JOINT MAKER When we had a chance to work with the Joint Maker in the Popular Woodworking shop, we were definitely impressed with the cleverness of the design. Our minds were spinning with the amazing number of operations that could be performed easily with this homemade jig. We also let our minds wander a little further about some of the features of the jig. After adjusting the numerous wing nuts (especially when applying hold-down torque to such a small surface area), we decided that some very affordable handles would make the jig more user-friendly. T-handle, star and three-wing knobs are available for 50 cents to $2 each, and make gripping and tightening the adjusters a whole heck of a lot easier. Another addition we felt would be useful were some optional manufactured hold-downs. While Nick's hold-downs function well, there are a number of other hold-downs available for less than $5 that offer slightly better perform-ance.The store-bought hold-downs shown at right will work with the slots as shown in the plans, and by purchasing them you'll reduce the time necessary to build the jig and get you using it more quickly. Both the knobs and hold downs shown here are available from Hartville Tool (800-345-2396 or hartvilletool.com). The knobs (right) are made from recycled plastic and available as two-prong (item #60936), three-prong (item #60866) or four-prong (item #60796). Each costs 89 cents. The hold-down unit below left (item #60736) costs $3.99 and includes a solid aluminum hold-down, a bolt and a V4"-20 knob. - David Thiel While the four-prong "star" knobs are easiest to grab, the two-prong "T" knobs require less clearance.The hold-down at left also works in the Joint Maker's slots. 82 Popular Woodworking February 2004 |