Popular Woodworking 2004-02 № 139, страница 87

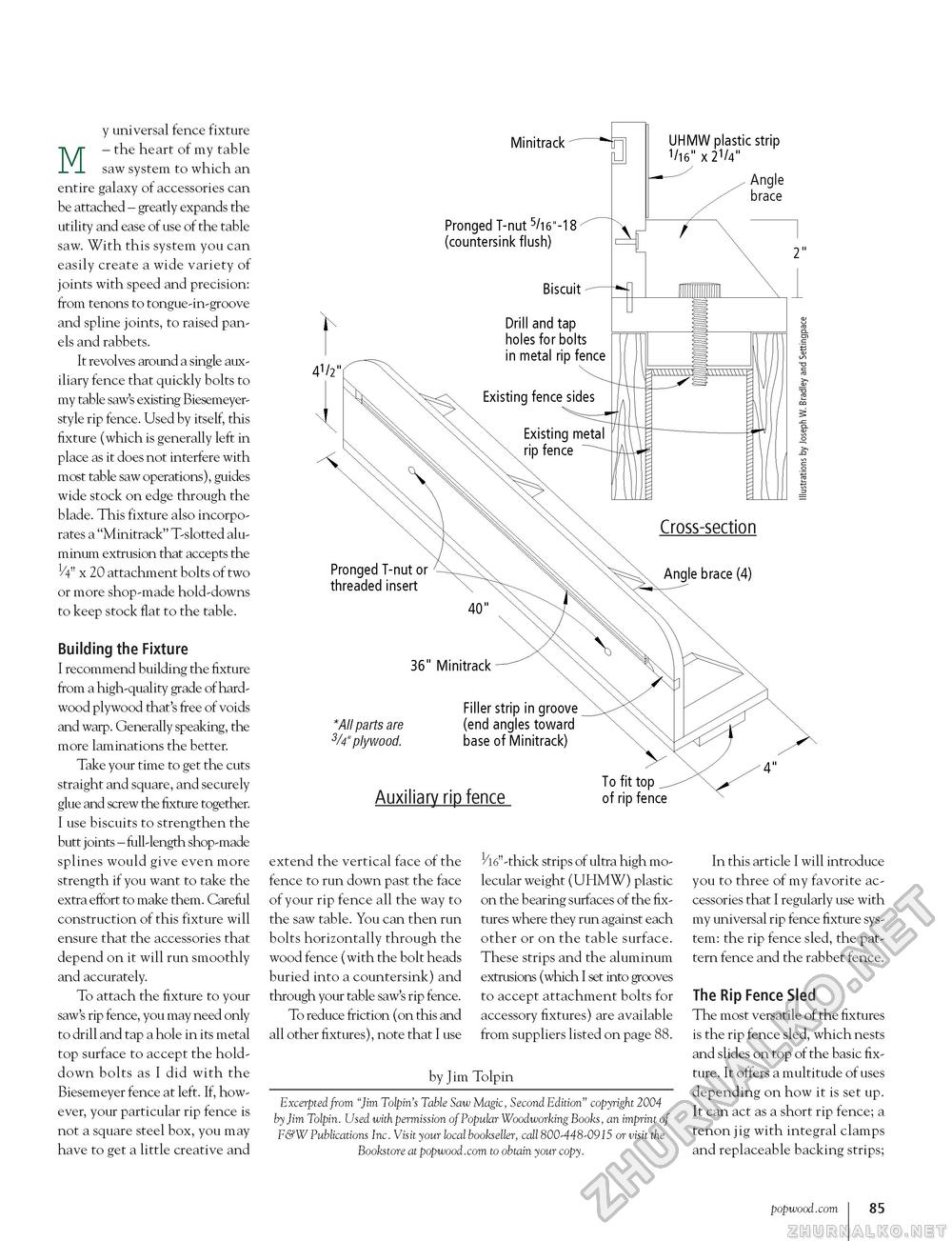

y universal fence fixture M- the heart of my table saw system to which an entire galaxy of accessories can be attached - greatly expands the utility and ease of use of the table saw. With this system you can easily create a wide variety of joints with speed and precision: from tenons to tongue-in-groove and spline joints, to raised panels and rabbets. It revolves around a single auxiliary fence that quickly bolts to my table saw's existing Biesemeyer-style rip fence. Used by itself, this fixture (which is generally left in place as it does not interfere with most table saw operations), guides wide stock on edge through the blade. This fixture also incorporates a "Minitrack" T-slotted aluminum extrusion that accepts the H" x 20 attachment bolts of two or more shop-made hold-downs to keep stock flat to the table. Building the Fixture I recommend building the fixture from a high-quality grade of hardwood plywood that's free of voids and warp. Generally speaking, the more laminations the better. Take your time to get the cuts straight and square, and securely glue and screw the fixture together. I use biscuits to strengthen the butt joints - full-length shop-made splines would give even more strength if you want to take the extra effort to make them. Careful construction of this fixture will ensure that the accessories that depend on it will run smoothly and accurately. To attach the fixture to your saw's rip fence, you may need only to drill and tap a hole in its metal top surface to accept the hold-down bolts as I did with the Biesemeyer fence at left. If, however, your particular rip fence is not a square steel box, you may have to get a little creative and extend the vertical face of the fence to run down past the face of your rip fence all the way to the saw table. You can then run bolts horizontally through the wood fence (with the bolt heads buried into a countersink) and through your table saw's rip fence. To reduce friction (on this and all other fixtures), note that I use i/16" -thick strips of ultra high molecular weight (UHMW) plastic on the bearing surfaces of the fixtures where they run against each other or on the table surface. These strips and the aluminum extrusions (which I set into grooves to accept attachment bolts for accessory fixtures) are available from suppliers listed on page 88. In this article I will introduce you to three of my favorite accessories that I regularly use with my universal rip fence fixture system: the rip fence sled, the pattern fence and the rabbet fence. The Rip Fence Sled The most versatile of the fixtures is the rip fence sled, which nests and slides on top of the basic fixture. It offers a multitude of uses depending on how it is set up. It can act as a short rip fence; a tenon jig with integral clamps and replaceable backing strips; by Jim Tolpin Excerpted from "Jim Tolpin's Table Saw Magic, Second Edition" copyright 2004 by Jim Tolpin. Used with permission of Popular Woodworking Books, an imprint of F&W Publications Inc. Visit your local bookseller, call 800-448-0915 or visit the Bookstore at popwood.com to obtain your copy. popwood.com 85 |