Popular Woodworking 2004-02 № 139, страница 88

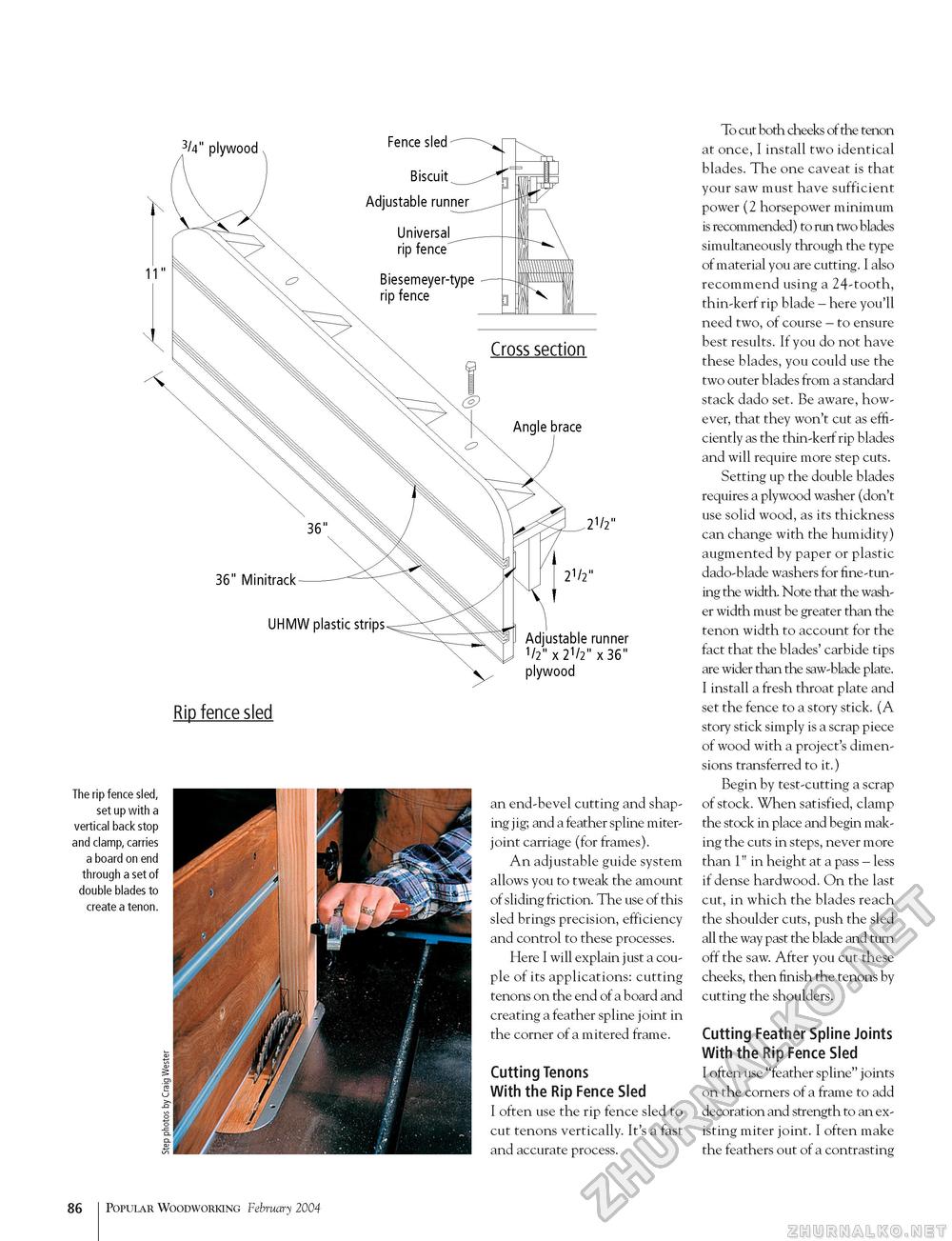

3/4" plywood 36" Minitrack Fence sled Biscuit ^ Adjustable runner ■fg UHMW plastic strips Cross section Adjustable runner 1/2" x 21/2" x 36" plywood Rip fence sled The rip fence sled, set up with a vertical back stop and clamp, carries a board on end through a set of double blades to create a tenon. an end-bevel cutting and shaping jig; and a feather spline miter-joint carriage (for frames). An adjustable guide system allows you to tweak the amount of sliding friction. The use of this sled brings precision, efficiency and control to these processes. Here I will explain just a couple of its applications: cutting tenons on the end of a board and creating a feather spline joint in the corner of a mitered frame. Cutting Tenons With the Rip Fence Sled I often use the rip fence sled to cut tenons vertically. It's a fast and accurate process. To cut both cheeks of the tenon at once, I install two identical blades. The one caveat is that your saw must have sufficient power (2 horsepower minimum is recommended) to run two blades simultaneously through the type of material you are cutting. I also recommend using a 24-tooth, thin-kerf rip blade - here you'll need two, of course - to ensure best results. If you do not have these blades, you could use the two outer blades from a standard stack dado set. Be aware, however, that they won't cut as efficiently as the thin-kerf rip blades and will require more step cuts. Setting up the double blades requires a plywood washer (don't use solid wood, as its thickness can change with the humidity) augmented by paper or plastic dado-blade washers for fine-tuning the width. Note that the washer width must be greater than the tenon width to account for the fact that the blades' carbide tips are wider than the saw-blade plate. I install a fresh throat plate and set the fence to a story stick. (A story stick simply is a scrap piece of wood with a project's dimensions transferred to it.) Begin by test-cutting a scrap of stock. When satisfied, clamp the stock in place and begin making the cuts in steps, never more than 1" in height at a pass - less if dense hardwood. On the last cut, in which the blades reach the shoulder cuts, push the sled all the way past the blade and turn off the saw. After you cut these cheeks, then finish the tenons by cutting the shoulders. Cutting Feather Spline Joints With the Rip Fence Sled I often use "feather spline" joints on the corners of a frame to add decoration and strength to an existing miter joint. I often make the feathers out of a contrasting 86 Popular Woodworking February 2004 |