Popular Woodworking 2004-04 № 140, страница 51

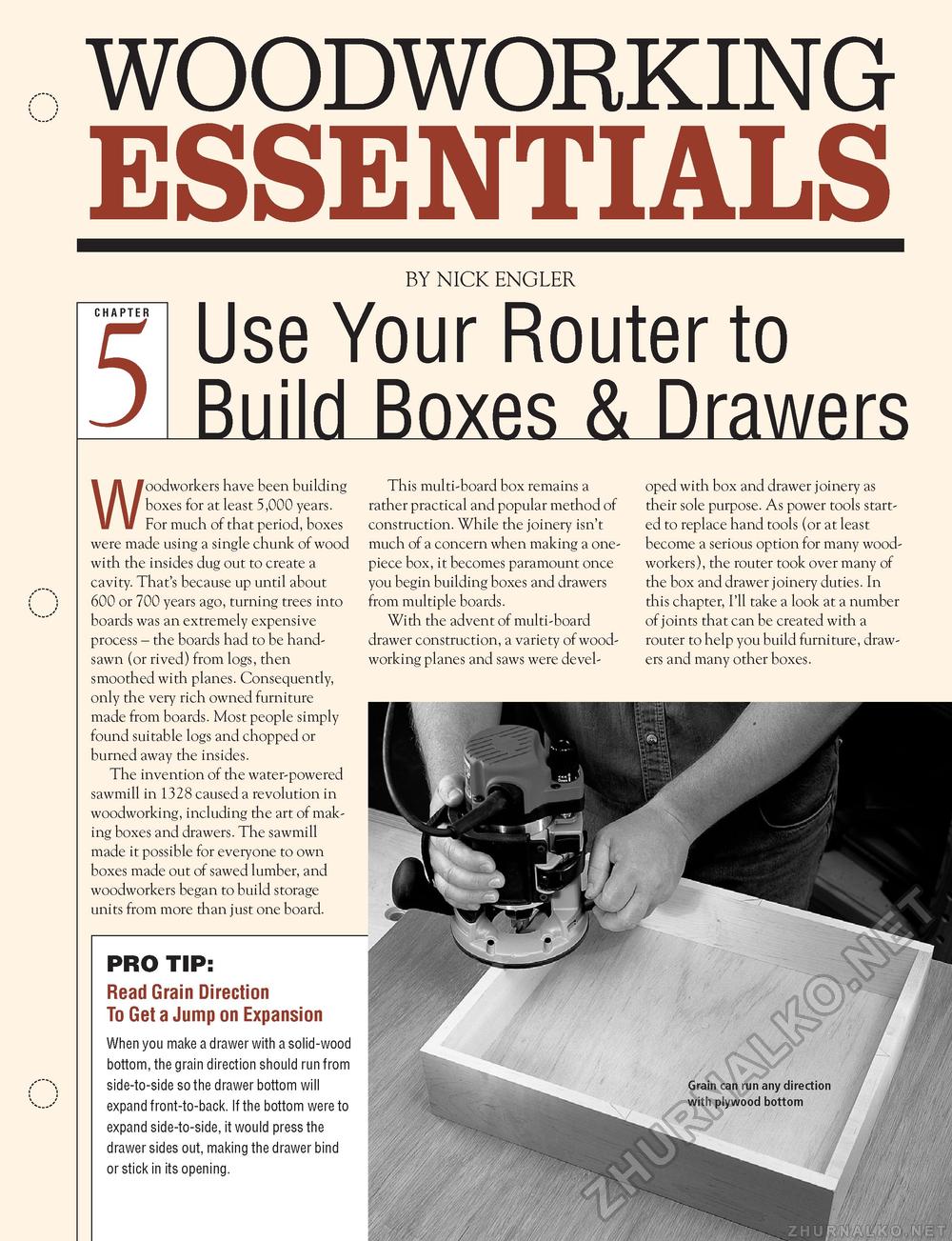

WOODWORKING ESSENTIALS BY NICK ENGLER Use Your Router to Builrl Boxes' & Drawers WF oodworkers have been building boxes for at least 5,000 years. For much of that period, boxes were made using a single chunk of wood with the insides dug out to create a cavity. That's because up until about 600 or 700 years ago, turning trees into boards was an extremely expensive process - the boards had to be hand-sawn (or rived) from logs, then smoothed with planes. Consequently, only the very rich owned furniture made from boards. Most people simply found suitable logs and chopped or burned away the insides. The invention of the water-powered sawmill in 1328 caused a revolution in woodworking, including the art of making boxes and drawers. The sawmill made it possible for everyone to own boxes made out of sawed lumber, and woodworkers began to build storage units from more than just one board. This multi-board box remains a rather practical and popular method of construction. While the joinery isn't much of a concern when making a one-piece box, it becomes paramount once you begin building boxes and drawers from multiple boards. With the advent of multi-board drawer construction, a variety of woodworking planes and saws were devel oped with box and drawer joinery as their sole purpose. As power tools started to replace hand tools (or at least become a serious option for many woodworkers), the router took over many of the box and drawer joinery duties. In this chapter, I'll take a look at a number of joints that can be created with a router to help you build furniture, drawers and many other boxes. PRO TIP: Read Grain Direction To Get a Jump on Expansion When you make a drawer with a solid-wood bottom, the grain direction should run from side-to-side so the drawer bottom will expand front-to-back. If the bottom were to expand side-to-side, it would press the drawer sides out, making the drawer bind or stick in its opening. |