Popular Woodworking 2004-04 № 140, страница 52

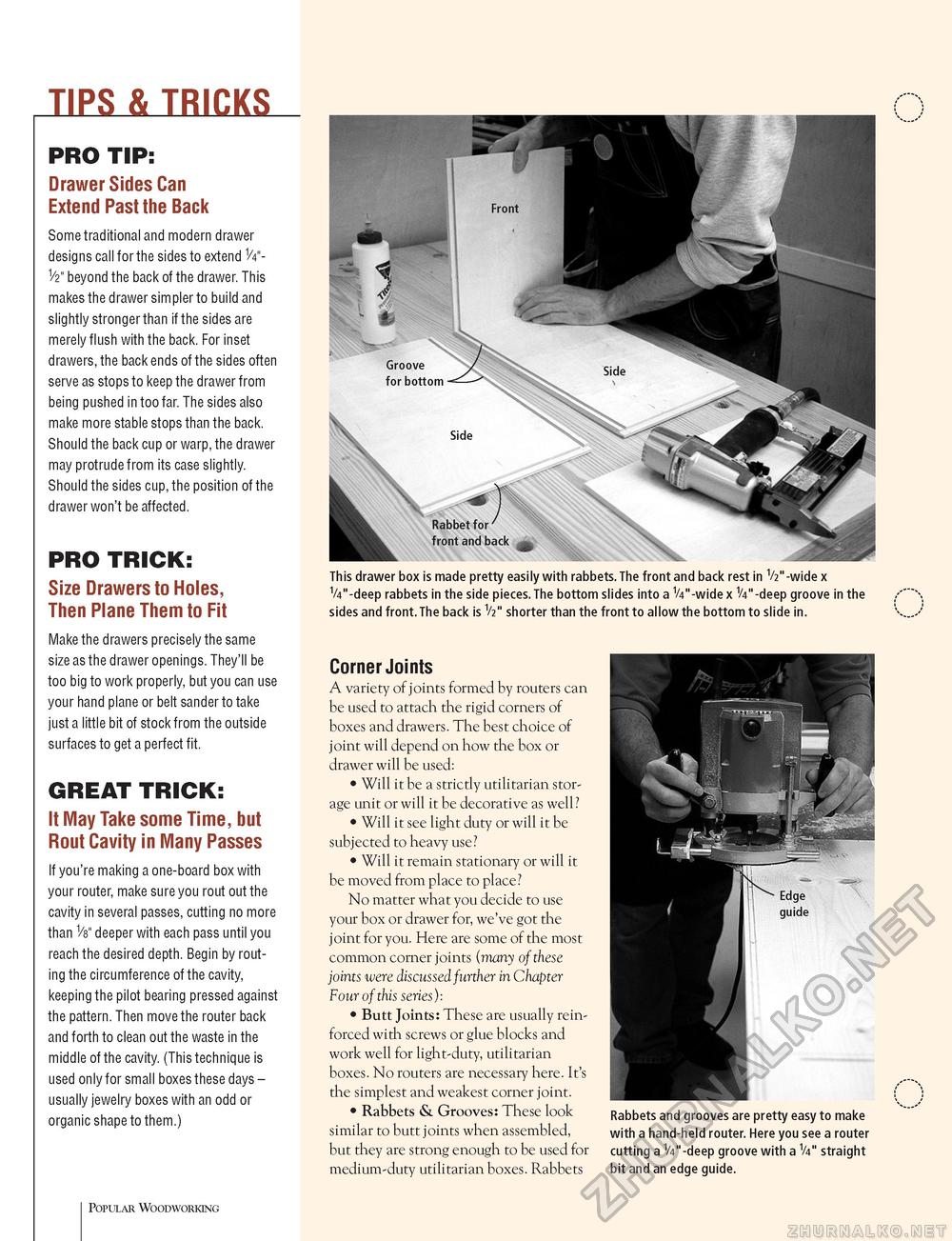

TIPS & TRICKS PRO TIP: Drawer Sides Can Extend Past the Back Some traditional and modern drawer designs call for the sides to extend 1/4"-1/2" beyond the back of the drawer. This makes the drawer simpler to build and slightly stronger than if the sides are merely flush with the back. For inset drawers, the back ends of the sides often serve as stops to keep the drawer from being pushed in too far. The sides also make more stable stops than the back. Should the back cup or warp, the drawer may protrude from its case slightly. Should the sides cup, the position of the drawer won't be affected. PRO TRICK: Size Drawers to Holes, Then Plane Them to Fit Make the drawers precisely the same size as the drawer openings. They'll be too big to work properly, but you can use your hand plane or belt sander to take just a little bit of stock from the outside surfaces to get a perfect fit. GREAT TRICK: It May Take some Time, but Rout Cavity in Many Passes If you're making a one-board box with your router, make sure you rout out the cavity in several passes, cutting no more than Vs" deeper with each pass until you reach the desired depth. Begin by routing the circumference of the cavity, keeping the pilot bearing pressed against the pattern. Then move the router back and forth to clean out the waste in the middle of the cavity. (This technique is used only for small boxes these days -usually jewelry boxes with an odd or organic shape to them.) This drawer box is made pretty easily with rabbets. The front and back rest in 1/2"-wide x 1/4"-deep rabbets in the side pieces. The bottom slides into a 1/4"-wide x 1/4"-deep groove in the sides and front.The back is V2" shorter than the front to allow the bottom to slide in. Corner Joints A variety of joints formed by routers can be used to attach the rigid corners of boxes and drawers. The best choice of joint will depend on how the box or drawer will be used: • Will it be a strictly utilitarian storage unit or will it be decorative as well? • Will it see light duty or will it be subjected to heavy use? • Will it remain stationary or will it be moved from place to place? No matter what you decide to use your box or drawer for, we've got the joint for you. Here are some of the most common corner joints (many of these joints were discussed further in Chapter Four of this series): • Butt Joints: These are usually reinforced with screws or glue blocks and work well for light-duty, utilitarian boxes. No routers are necessary here. It's the simplest and weakest corner joint. • Rabbets & Grooves: These look similar to butt joints when assembled, but they are strong enough to be used for medium-duty utilitarian boxes. Rabbets Rabbets and grooves are pretty easy to make with a hand-held router. Here you see a router cutting a V4"-deep groove with a V4" straight bit and an edge guide. Popular Woodworking |