Popular Woodworking 2004-04 № 140, страница 54

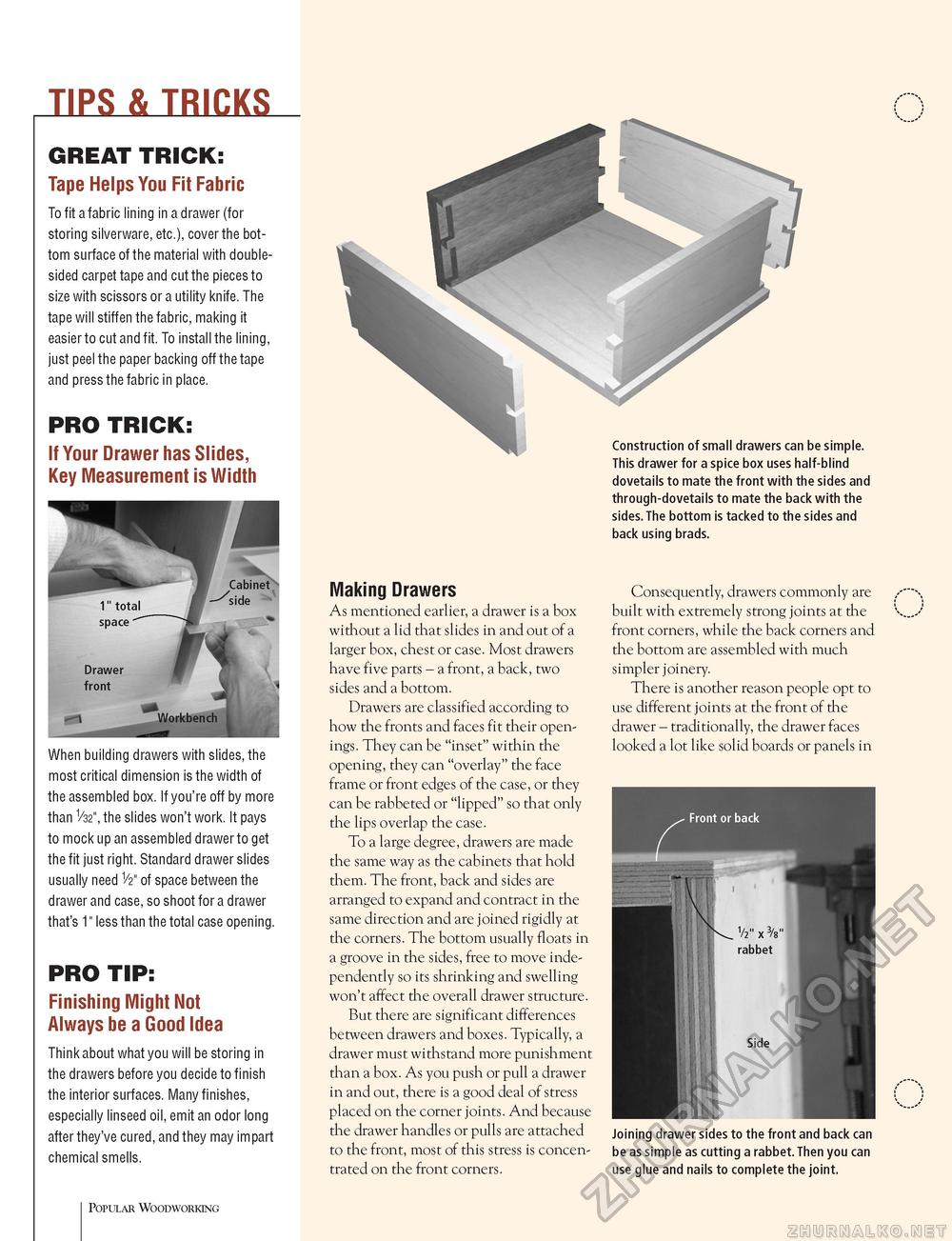

TIPS & TRICKS GREAT TRICK: Tape Helps You Fit Fabric To fit a fabric lining in a drawer (for storing silverware, etc.), cover the bottom surface of the material with double-sided carpet tape and cut the pieces to size with scissors or a utility knife. The tape will stiffen the fabric, making it easier to cut and fit. To install the lining, just peel the paper backing off the tape and press the fabric in place. PRO TRICK: If Your Drawer has Slides, Key Measurement is Width When building drawers with slides, the most critical dimension is the width of the assembled box. If you're off by more than V32", the slides won't work. It pays to mock up an assembled drawer to get the fit just right. Standard drawer slides usually need V2" of space between the drawer and case, so shoot for a drawer that's 1" less than the total case opening. PRO TIP: Finishing Might Not Always be a Good Idea Think about what you will be storing in the drawers before you decide to finish the interior surfaces. Many finishes, especially linseed oil, emit an odor long after they've cured, and they may impart chemical smells. Construction of small drawers can be simple. This drawer for a spice box uses half-blind dovetails to mate the front with the sides and through-dovetails to mate the back with the sides. The bottom is tacked to the sides and back using brads. Making Drawers As mentioned earlier, a drawer is a box without a lid that slides in and out of a larger box, chest or case. Most drawers have five parts - a front, a back, two sides and a bottom. Drawers are classified according to how the fronts and faces fit their openings. They can be "inset" within the opening, they can "overlay" the face frame or front edges of the case, or they can be rabbeted or "lipped" so that only the lips overlap the case. To a large degree, drawers are made the same way as the cabinets that hold them. The front, back and sides are arranged to expand and contract in the same direction and are joined rigidly at the corners. The bottom usually floats in a groove in the sides, free to move independently so its shrinking and swelling won't affect the overall drawer structure. But there are significant differences between drawers and boxes. Typically, a drawer must withstand more punishment than a box. As you push or pull a drawer in and out, there is a good deal of stress placed on the corner joints. And because the drawer handles or pulls are attached to the front, most of this stress is concentrated on the front corners. Consequently, drawers commonly are built with extremely strong joints at the front corners, while the back corners and the bottom are assembled with much simpler joinery. There is another reason people opt to use different joints at the front of the drawer - traditionally, the drawer faces looked a lot like solid boards or panels in Joining drawer sides to the front and back can be as simple as cutting a rabbet. Then you can use glue and nails to complete the joint. Popular Woodworking |