Popular Woodworking 2004-04 № 140, страница 56

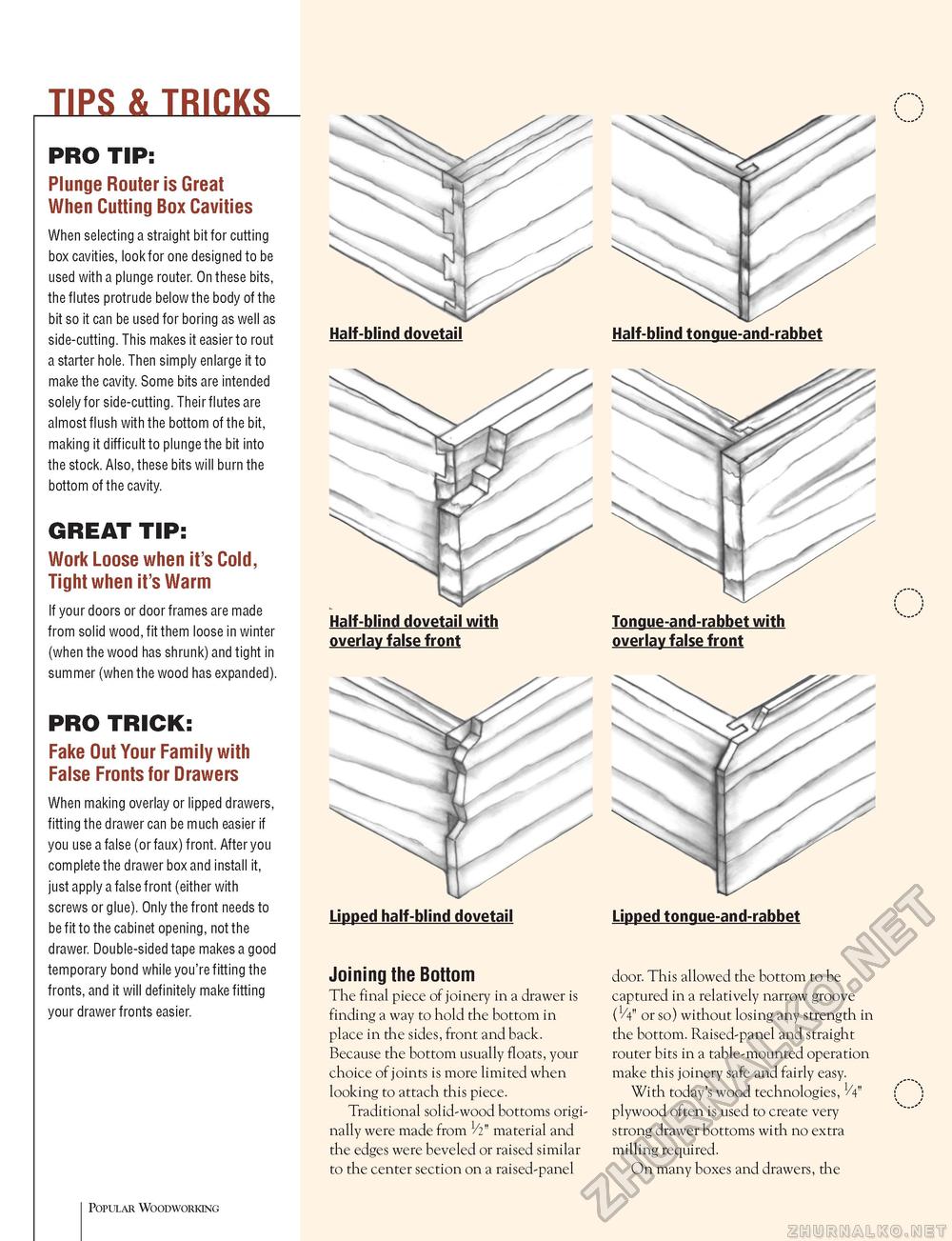

TIPS & TRICKS PRO TIP: Plunge Router is Great When Cutting Box Cavities When selecting a straight bit for cutting box cavities, look for one designed to be used with a plunge router. On these bits, the flutes protrude below the body of the bit so it can be used for boring as well as side-cutting. This makes it easier to rout a starter hole. Then simply enlarge it to make the cavity. Some bits are intended solely for side-cutting. Their flutes are almost flush with the bottom of the bit, making it difficult to plunge the bit into the stock. Also, these bits will burn the bottom of the cavity. GREAT TIP: Work Loose when it's Cold, Tight when it's Warm If your doors or door frames are made from solid wood, fit them loose in winter (when the wood has shrunk) and tight in summer (when the wood has expanded). PRO TRICK: Fake Out Your Family with False Fronts for Drawers When making overlay or lipped drawers, fitting the drawer can be much easier if you use a false (or faux) front. After you complete the drawer box and install it, just apply a false front (either with screws or glue). Only the front needs to be fit to the cabinet opening, not the drawer. Double-sided tape makes a good temporary bond while you're fitting the fronts, and it will definitely make fitting your drawer fronts easier. Half-blind dovetail Half-blind dovetail with overlay false front Lipped half-blind dovetail Joining the Bottom The final piece of joinery in a drawer is finding a way to hold the bottom in place in the sides, front and back. Because the bottom usually floats, your choice of joints is more limited when looking to attach this piece. Traditional solid-wood bottoms originally were made from V2" material and the edges were beveled or raised similar to the center section on a raised-panel Half-blind tongue-and-rabbet Tongue-and-rabbet with overlay false front Lipped tongue-and-rabbet door. This allowed the bottom to be captured in a relatively narrow groove (1/4" or so) without losing any strength in the bottom. Raised-panel and straight router bits in a table-mounted operation make this joinery safe and fairly easy. With today's wood technologies, 1/4" plywood often is used to create very strong drawer bottoms with no extra milling required. On many boxes and drawers, the Popular Woodworking |