Popular Woodworking 2004-04 № 140, страница 74

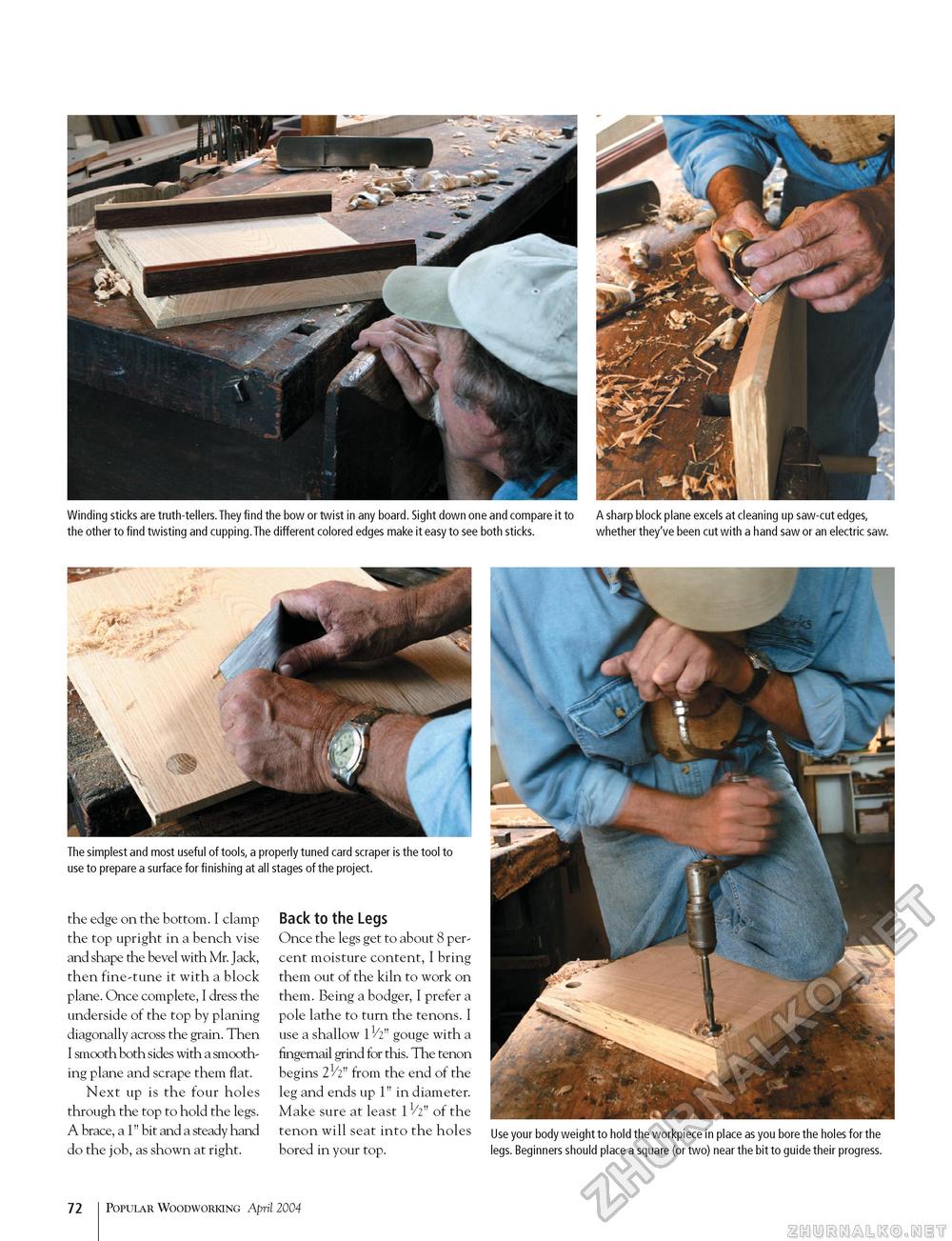

Winding sticks are truth-tellers. They find the bow or twist in any board. Sight down one and compare it to the other to find twisting and cupping.The different colored edges make it easy to see both sticks. A sharp block plane excels at cleaning up saw-cut edges, whether they've been cut with a hand saw or an electric saw. The simplest and most useful of tools, a properly tuned card scraper is the tool to use to prepare a surface for finishing at all stages of the project. the edge on the bottom. I clamp the top upright in a bench vise and shape the bevel with Mr. Jack, then fine-tune it with a block plane. Once complete, I dress the underside of the top by planing diagonally across the grain. Then I smooth both sides with a smoothing plane and scrape them flat. Next up is the four holes through the top to hold the legs. A brace, a 1" bit and a steady hand do the job, as shown at right. Back to the Legs Once the legs get to about 8 percent moisture content, I bring them out of the kiln to work on them. Being a bodger, I prefer a pole lathe to turn the tenons. I use a shallow 11/2" gouge with a fingernail grind for this. The tenon begins 21/2" from the end of the leg and ends up 1" in diameter. Make sure at least 11/2" of the tenon will seat into the holes bored in your top. Use your body weight to hold the workpiece in place as you bore the holes for the legs. Beginners should place a square (or two) near the bit to guide their progress. 72 Popular Woodworking April 2004 |