Popular Woodworking 2004-06 № 141, страница 55

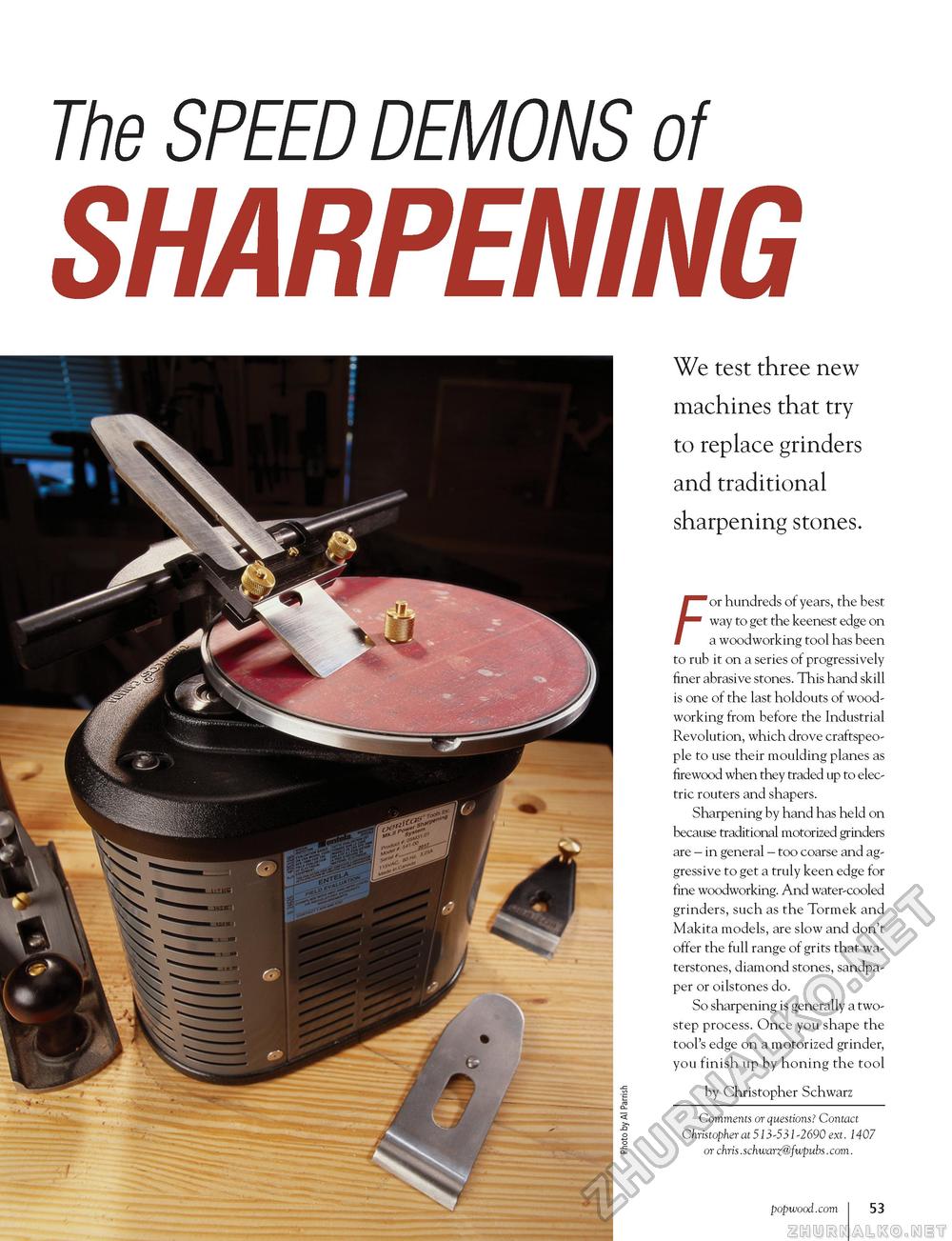

The SPEED DEMONS of SHARPENINGWe test three new machines that try to replace grinders and traditional sharpening stones. or hundreds of years, the best way to get the keenest edge on a woodworking tool has been to rub it on a series of progressively finer abrasive stones. This hand skill is one of the last holdouts of woodworking from before the Industrial Revolution, which drove craftspeople to use their moulding planes as firewood when they traded up to electric routers and shapers. Sharpening by hand has held on because traditional motorized grinders are - in general - too coarse and aggressive to get a truly keen edge for fine woodworking. And water-cooled grinders, such as the Tormek and Makita models, are slow and don't offer the full range of grits that wa-terstones, diamond stones, sandpaper or oilstones do. So sharpening is generally a two-step process. Once you shape the tool's edge on a motorized grinder, you finish up by honing the tool by Christopher Schwarz Comments or questions? Contact Christopher at 513-531-2690 ext. 1407 or chris.schwarz@fwpubs.com. popwood.com 53 |