Popular Woodworking 2004-06 № 141, страница 92

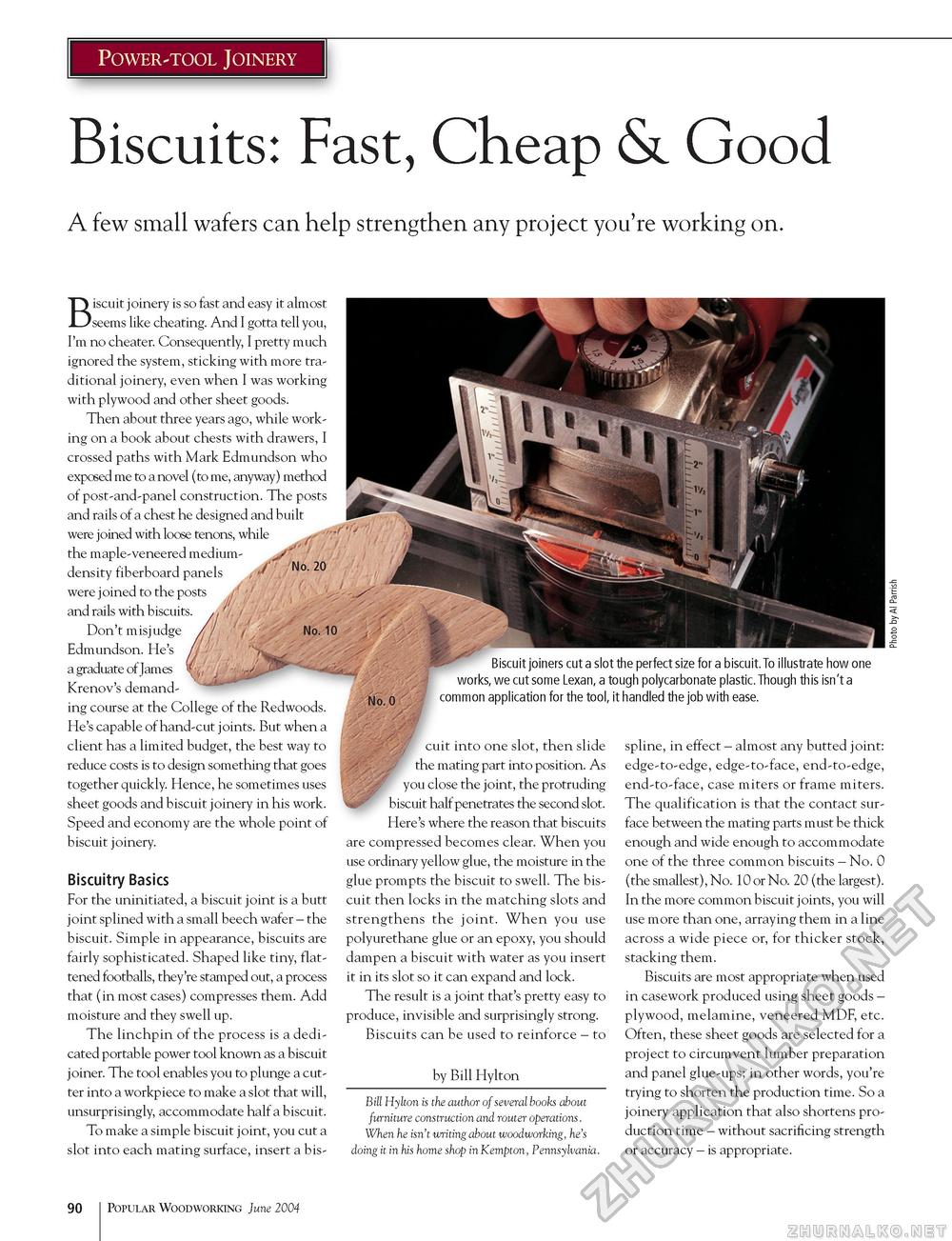

Power-tool Joinery Biscuits: Fast, Cheap & Good A few small wafers can help strengthen any project you're working on. Biscuit joinery is so fast and easy it almost seems like cheating. And I gotta tell you, I'm no cheater. Consequently, I pretty much ignored the system, sticking with more traditional joinery, even when I was working with plywood and other sheet goods. Then about three years ago, while working on a book about chests with drawers, I crossed paths with Mark Edmundson who exposed me to a novel (to me, anyway) method of post-and-panel construction. The posts and rails of a chest he designed and built were joined with loose tenons, while j/ ' the maple-veneered medium- ' density fiberboard panels , . were joined to the posts ./' 1 and rails with biscuits. ,, 'L '/ Don't misjudge A J / / No. 20 'C\!\ No. 10 Edmundson. He's a graduate of James Krenov's demanding course at the College of the Redwoods. He's capable of hand-cut joints. But when a client has a limited budget, the best way to reduce costs is to design something that goes together quickly. Hence, he sometimes uses sheet goods and biscuit joinery in his work. Speed and economy are the whole point of biscuit joinery. Biscuitry Basics For the uninitiated, a biscuit joint is a butt joint splined with a small beech wafer - the biscuit. Simple in appearance, biscuits are fairly sophisticated. Shaped like tiny, flattened footballs, they're stamped out, a process that (in most cases) compresses them. Add moisture and they swell up. The linchpin of the process is a dedicated portable power tool known as a biscuit joiner. The tool enables you to plunge a cutter into a workpiece to make a slot that will, unsurprisingly, accommodate half a biscuit. To make a simple biscuit joint, you cut a slot into each mating surface, insert a bis Biscuit joiners cut a slot the perfect size for a biscuit. To illustrate how one works, we cut some Lexan, a tough polycarbonate plastic. Though this isn't a No 0 ^ common application for the tool, it handled the job with ease. «B imf cuit into one slot, then slide the mating part into position. As you close the joint, the protruding biscuit half penetrates the second slot. Here's where the reason that biscuits are compressed becomes clear. When you use ordinary yellow glue, the moisture in the glue prompts the biscuit to swell. The biscuit then locks in the matching slots and strengthens the joint. When you use polyurethane glue or an epoxy, you should dampen a biscuit with water as you insert it in its slot so it can expand and lock. The result is a joint that's pretty easy to produce, invisible and surprisingly strong. Biscuits can be used to reinforce - to by Bill Hylton Bill Hylton is the author of several books about furniture construction and router operations. When he isn't writing about woodworking, he's doing it in his home shop in Kempton, Pennsylvania. spline, in effect - almost any butted joint: edge-to-edge, edge-to-face, end-to-edge, end-to-face, case miters or frame miters. The qualification is that the contact surface between the mating parts must be thick enough and wide enough to accommodate one of the three common biscuits - No. 0 (the smallest), No. 10 or No. 20 (the largest). In the more common biscuit joints, you will use more than one, arraying them in a line across a wide piece or, for thicker stock, stacking them. Biscuits are most appropriate when used in casework produced using sheet goods -plywood, melamine, veneered MDF, etc. Often, these sheet goods are selected for a project to circumvent lumber preparation and panel glue-ups; in other words, you're trying to shorten the production time. So a joinery application that also shortens production time - without sacrificing strength or accuracy - is appropriate. 90 Popular Woodworking June 2004 |