Popular Woodworking 2004-06 № 141, страница 93

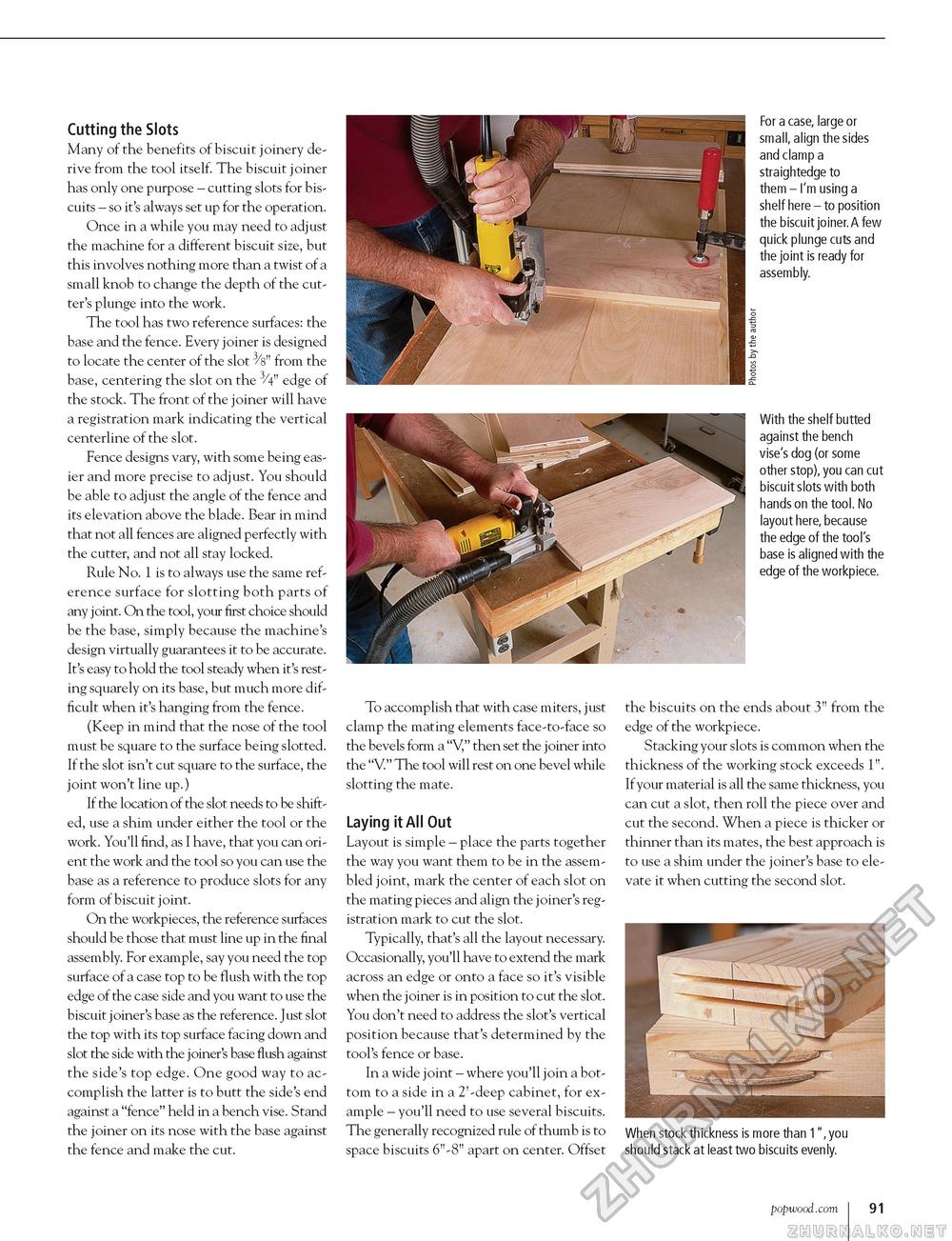

For a case, large or small, align the sides and clamp a straightedge to them - I'm using a shelf here - to position the biscuit joiner. A few quick plunge cuts and the joint is ready for assembly. With the shelf butted against the bench vise's dog (or some other stop), you can cut biscuit slots with both hands on the tool. No layout here, because the edge of the tool's base is aligned with the edge of the workpiece. Cutting the Slots Many of the benefits of biscuit joinery derive from the tool itself. The biscuit joiner has only one purpose - cutting slots for biscuits - so it's always set up for the operation. Once in a while you may need to adjust the machine for a different biscuit size, but this involves nothing more than a twist of a small knob to change the depth of the cutter's plunge into the work. The tool has two reference surfaces: the base and the fence. Every joiner is designed to locate the center of the slot 3/s" from the base, centering the slot on the 3/4" edge of the stock. The front of the joiner will have a registration mark indicating the vertical centerline of the slot. Fence designs vary, with some being easier and more precise to adjust. You should be able to adjust the angle of the fence and its elevation above the blade. Bear in mind that not all fences are aligned perfectly with the cutter, and not all stay locked. Rule No. 1 is to always use the same reference surface for slotting both parts of any joint. On the tool, your first choice should be the base, simply because the machine's design virtually guarantees it to be accurate. It's easy to hold the tool steady when it's resting squarely on its base, but much more difficult when it's hanging from the fence. (Keep in mind that the nose of the tool must be square to the surface being slotted. If the slot isn't cut square to the surface, the joint won't line up.) If the location of the slot needs to be shifted, use a shim under either the tool or the work. You'll find, as I have, that you can orient the work and the tool so you can use the base as a reference to produce slots for any form of biscuit joint. On the workpieces, the reference surfaces should be those that must line up in the final assembly. For example, say you need the top surface of a case top to be flush with the top edge of the case side and you want to use the biscuit joiner's base as the reference. Just slot the top with its top surface facing down and slot the side with the joiner's base flush against the side's top edge. One good way to accomplish the latter is to butt the side's end against a "fence" held in a bench vise. Stand the joiner on its nose with the base against the fence and make the cut. To accomplish that with case miters, just clamp the mating elements face-to-face so the bevels form a "V," then set the joiner into the "V." The tool will rest on one bevel while slotting the mate. Laying it All Out Layout is simple - place the parts together the way you want them to be in the assembled joint, mark the center of each slot on the mating pieces and align the joiner's registration mark to cut the slot. Typically, that's all the layout necessary. Occasionally, you'll have to extend the mark across an edge or onto a face so it's visible when the joiner is in position to cut the slot. You don't need to address the slot's vertical position because that's determined by the tool's fence or base. In a wide joint - where you'll join a bottom to a side in a 2'-deep cabinet, for example - you'll need to use several biscuits. The generally recognized rule of thumb is to space biscuits 6"-8" apart on center. Offset the biscuits on the ends about 3" from the edge of the workpiece. Stacking your slots is common when the thickness of the working stock exceeds 1". If your material is all the same thickness, you can cut a slot, then roll the piece over and cut the second. When a piece is thicker or thinner than its mates, the best approach is to use a shim under the joiner's base to elevate it when cutting the second slot. When stock thickness is more than 1",you should stack at least two biscuits evenly. popwood.com 91 |