Popular Woodworking 2004-08 № 142, страница 46

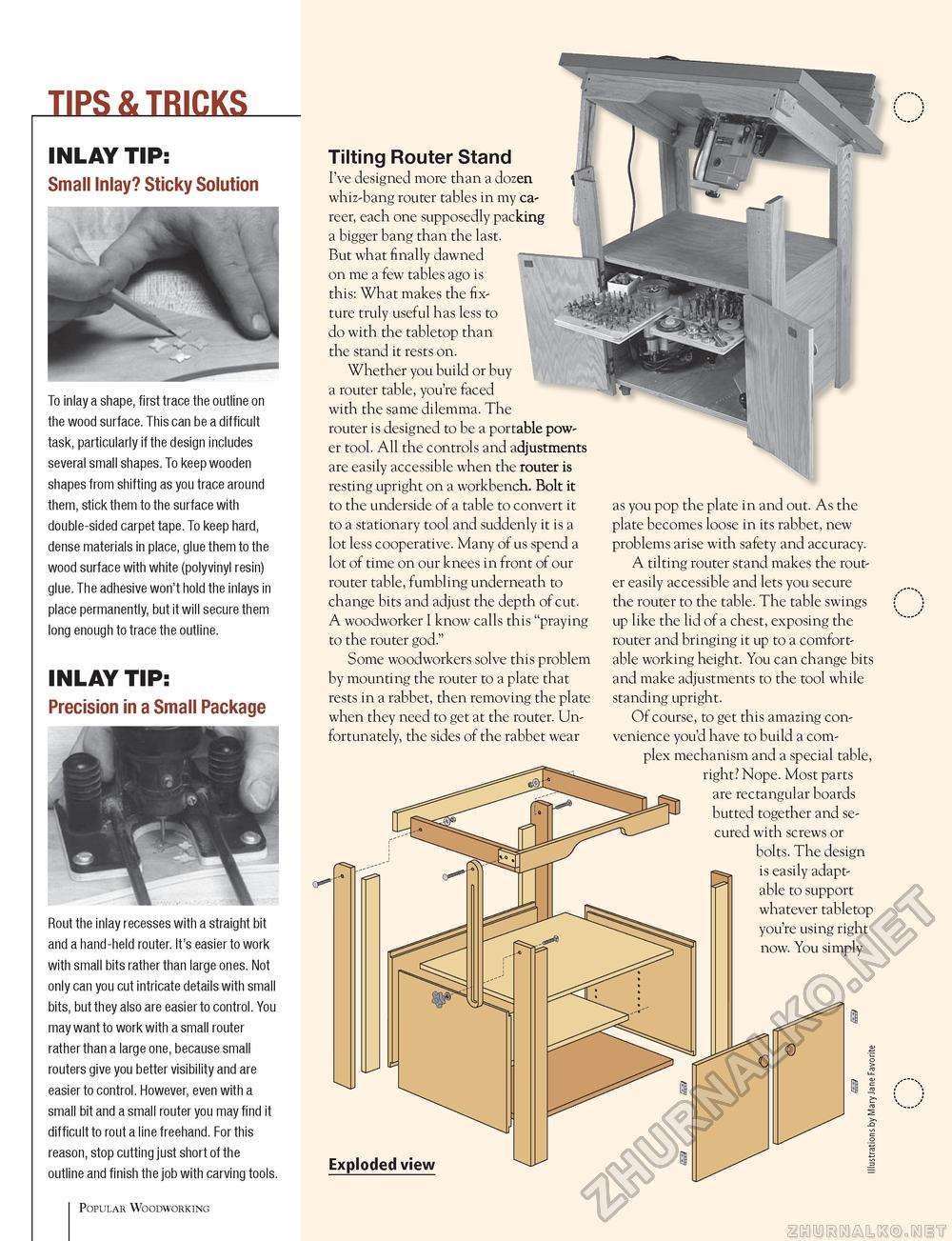

TIPS & TRICKS INLAY TIP: Small Inlay? Sticky Solution To inlay a shape, first trace the outline on the wood surface. This can be a difficult task, particularly if the design includes several small shapes. To keep wooden shapes from shifting as you trace around them, stick them to the surface with double-sided carpet tape. To keep hard, dense materials in place, glue them to the wood surface with white (polyvinyl resin) glue. The adhesive won't hold the inlays in place permanently, but it will secure them long enough to trace the outline. INLAY TIP: Precision in a Small Package Rout the inlay recesses with a straight bit and a hand-held router. It's easier to work with small bits rather than large ones. Not only can you cut intricate details with small bits, but they also are easier to control. You may want to work with a small router rather than a large one, because small routers give you better visibility and are easier to control. However, even with a small bit and a small router you may find it difficult to rout a line freehand. For this reason, stop cutting just short of the outline and finish the job with carving tools. Tilting Router Stand I've designed more than a dozen whiz-bang router tables in my career, each one supposedly packing a bigger bang than the last. But what finally dawned on me a few tables ago is this: What makes the fixture truly useful has less to do with the tabletop than the stand it rests on. Whether you build or buy a router table, you're faced with the same dilemma. The router is designed to be a portable power tool. All the controls and adjustments are easily accessible when the router is resting upright on a workbench. Bolt it to the underside of a table to convert it to a stationary tool and suddenly it is a lot less cooperative. Many of us spend a lot of time on our knees in front of our router table, fumbling underneath to change bits and adjust the depth of cut. A woodworker I know calls this "praying to the router god." Some woodworkers solve this problem by mounting the router to a plate that rests in a rabbet, then removing the plate when they need to get at the router. Unfortunately, the sides of the rabbet wear as you pop the plate in and out. As the plate becomes loose in its rabbet, new problems arise with safety and accuracy. A tilting router stand makes the router easily accessible and lets you secure the router to the table. The table swings up like the lid of a chest, exposing the router and bringing it up to a comfortable working height. You can change bits and make adjustments to the tool while standing upright. Of course, to get this amazing convenience you'd have to build a complex mechanism and a special table, right? Nope. Most parts are rectangular boards butted together and secured with screws or bolts. The design is easily adaptable to support whatever tabletop you're using right now. You simply Exploded view Popular Woodworking |