Popular Woodworking 2004-10 № 143, страница 57

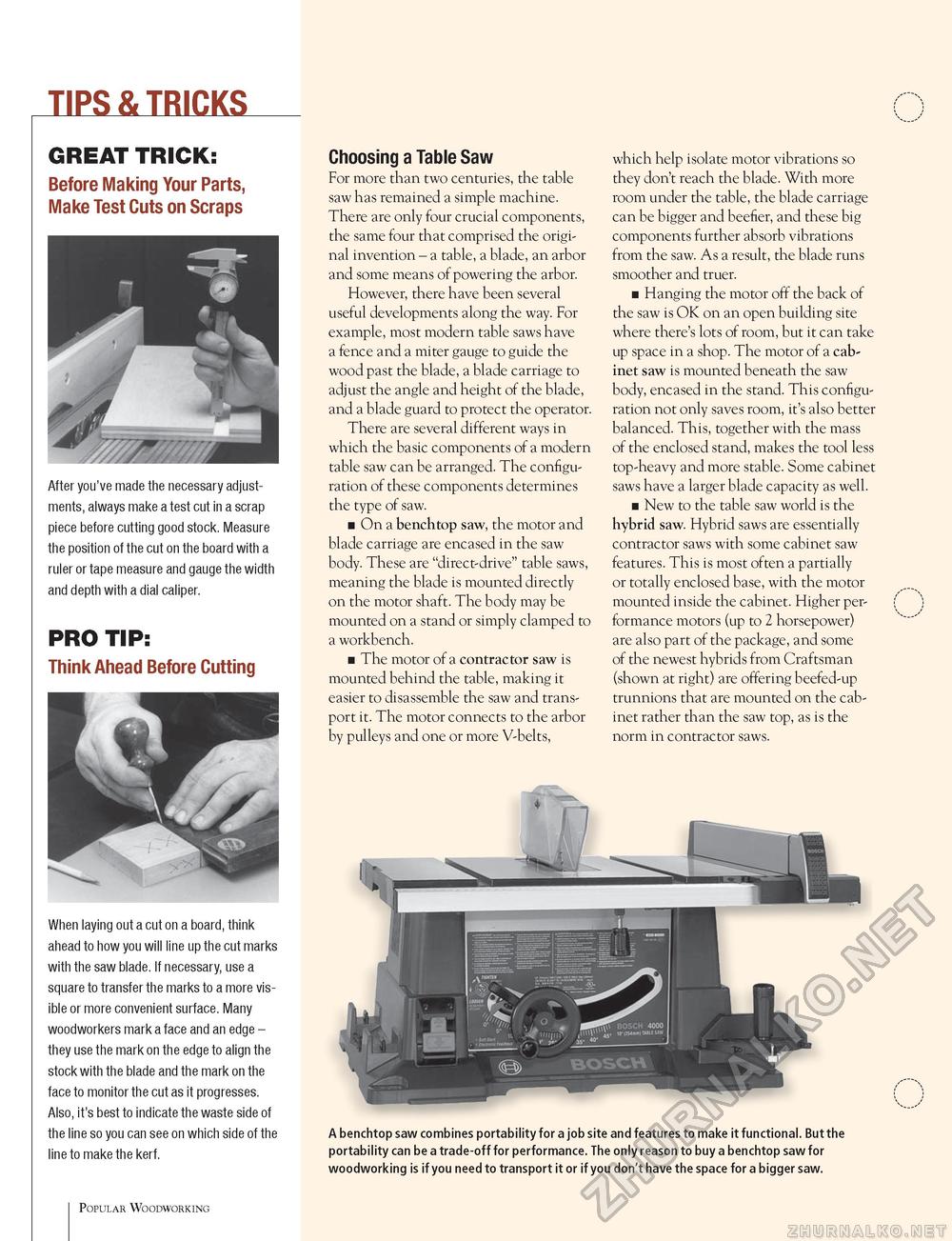

TIPS & TRICKS GREAT TRICK: Before Making Your Parts, Make Test Cuts on Scraps After you've made the necessary adjustments, always make a test cut in a scrap piece before cutting good stock. Measure the position of the cut on the board with a ruler or tape measure and gauge the width and depth with a dial caliper. PRO TIP: Think Ahead Before Cutting When laying out a cut on a board, think ahead to how you will line up the cut marks with the saw blade. If necessary, use a square to transfer the marks to a more visible or more convenient surface. Many woodworkers mark a face and an edge -they use the mark on the edge to align the stock with the blade and the mark on the face to monitor the cut as it progresses. Also, it's best to indicate the waste side of the line so you can see on which side of the line to make the kerf. Choosing a Table Saw For more than two centuries, the table saw has remained a simple machine. There are only four crucial components, the same four that comprised the original invention - a table, a blade, an arbor and some means of powering the arbor. However, there have been several useful developments along the way. For example, most modern table saws have a fence and a miter gauge to guide the wood past the blade, a blade carriage to adjust the angle and height of the blade, and a blade guard to protect the operator. There are several different ways in which the basic components of a modern table saw can be arranged. The configuration of these components determines the type of saw. ■ On a benchtop saw, the motor and blade carriage are encased in the saw body. These are "direct-drive" table saws, meaning the blade is mounted directly on the motor shaft. The body may be mounted on a stand or simply clamped to a workbench. ■ The motor of a contractor saw is mounted behind the table, making it easier to disassemble the saw and transport it. The motor connects to the arbor by pulleys and one or more V-belts, which help isolate motor vibrations so they don't reach the blade. With more room under the table, the blade carriage can be bigger and beefier, and these big components further absorb vibrations from the saw. As a result, the blade runs smoother and truer. ■ Hanging the motor off the back of the saw is OK on an open building site where there's lots of room, but it can take up space in a shop. The motor of a cabinet saw is mounted beneath the saw body, encased in the stand. This configuration not only saves room, it's also better balanced. This, together with the mass of the enclosed stand, makes the tool less top-heavy and more stable. Some cabinet saws have a larger blade capacity as well. ■ New to the table saw world is the hybrid saw. Hybrid saws are essentially contractor saws with some cabinet saw features. This is most often a partially or totally enclosed base, with the motor mounted inside the cabinet. Higher performance motors (up to 2 horsepower) are also part of the package, and some of the newest hybrids from Craftsman (shown at right) are offering beefed-up trunnions that are mounted on the cabinet rather than the saw top, as is the norm in contractor saws. A benchtop saw combines portability for a job site and features to make it functional. But the portability can be a trade-off for performance. The only reason to buy a benchtop saw for woodworking is if you need to transport it or if you don't have the space for a bigger saw. Popular Woodworking |