Popular Woodworking 2004-10 № 143, страница 60

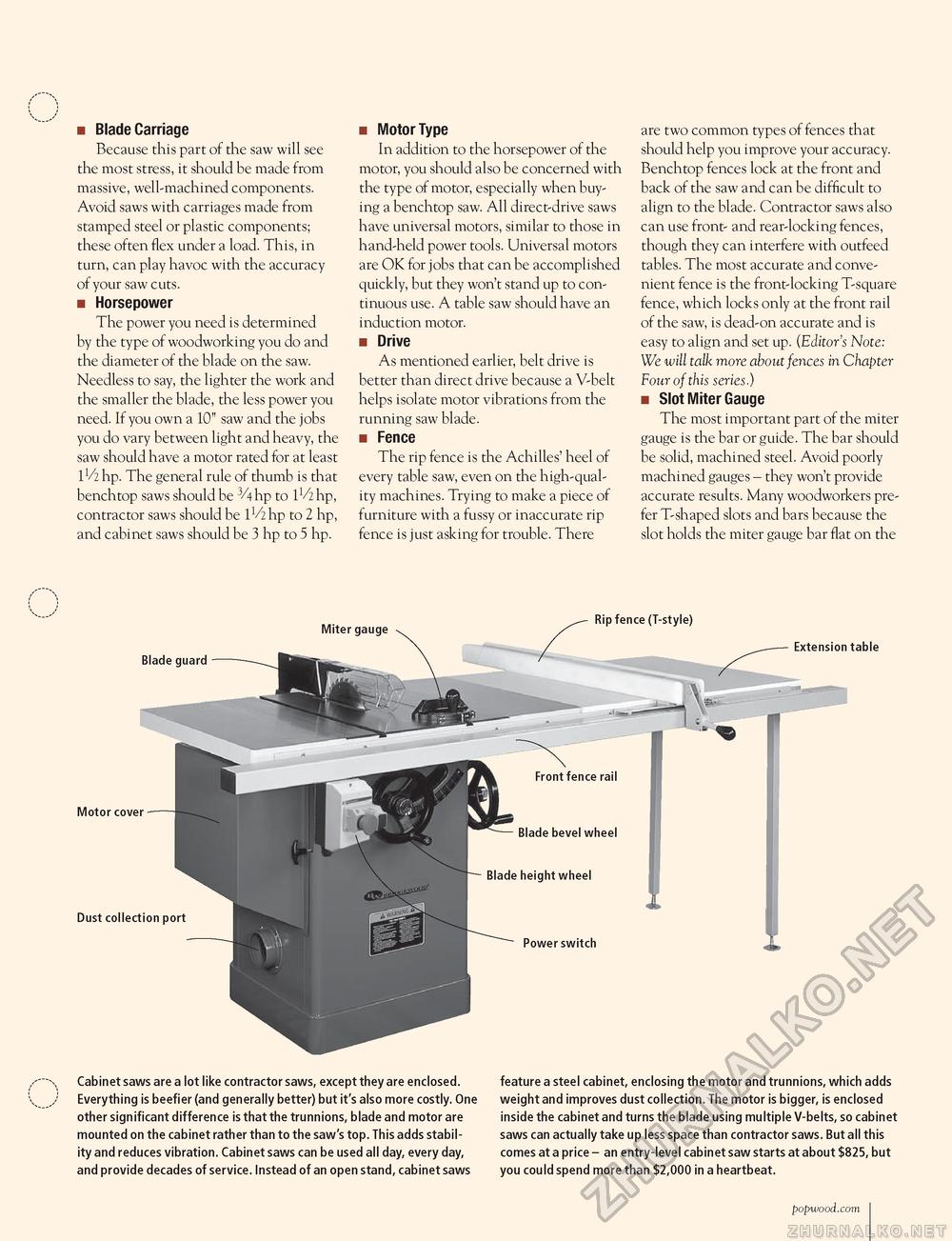

■ Blade Carriage Because this part of the saw will see the most stress, it should be made from massive, well-machined components. Avoid saws with carriages made from stamped steel or plastic components; these often flex under a load. This, in turn, can play havoc with the accuracy of your saw cuts. ■ Horsepower The power you need is determined by the type of woodworking you do and the diameter of the blade on the saw. Needless to say, the lighter the work and the smaller the blade, the less power you need. If you own a 10" saw and the jobs you do vary between light and heavy, the saw should have a motor rated for at least 1/2 hp. The general rule of thumb is that benchtop saws should be 3/4 hp to 1V2 hp, contractor saws should be l1/^ hp to 2 hp, and cabinet saws should be 3 hp to 5 hp. ■ Motor Type In addition to the horsepower of the motor, you should also be concerned with the type of motor, especially when buying a benchtop saw. All direct-drive saws have universal motors, similar to those in hand-held power tools. Universal motors are OK for jobs that can be accomplished quickly, but they won't stand up to continuous use. A table saw should have an induction motor. ■ Drive As mentioned earlier, belt drive is better than direct drive because a V-belt helps isolate motor vibrations from the running saw blade. ■ Fence The rip fence is the Achilles' heel of every table saw, even on the high-quality machines. Trying to make a piece of furniture with a fussy or inaccurate rip fence is just asking for trouble. There are two common types of fences that should help you improve your accuracy. Benchtop fences lock at the front and back of the saw and can be difficult to align to the blade. Contractor saws also can use front- and rear-locking fences, though they can interfere with outfeed tables. The most accurate and convenient fence is the front-locking T-square fence, which locks only at the front rail of the saw, is dead-on accurate and is easy to align and set up. (Editor's Note: We will talk more about fences in Chapter Four of this series.) ■ Slot Miter Gauge The most important part of the miter gauge is the bar or guide. The bar should be solid, machined steel. Avoid poorly machined gauges - they won't provide accurate results. Many woodworkers prefer T-shaped slots and bars because the slot holds the miter gauge bar flat on the Miter gauge Rip fence (T-style) Blade guard Extension table Motor cover Dust collection port Cabinet saws are a lot like contractor saws, except they are enclosed. Everything is beefier (and generally better) but it's also more costly. One other significant difference is that the trunnions, blade and motor are mounted on the cabinet rather than to the saw's top. This adds stability and reduces vibration. Cabinet saws can be used all day, every day, and provide decades of service. Instead of an open stand, cabinet saws feature a steel cabinet, enclosing the motor and trunnions, which adds weight and improves dust collection. The motor is bigger, is enclosed inside the cabinet and turns the blade using multiple V-belts, so cabinet saws can actually take up less space than contractor saws. But all this comes at a price - an entry-level cabinet saw starts at about $825, but you could spend more than $2,000 in a heartbeat. popwood.com 60 |