Popular Woodworking 2004-10 № 143, страница 62

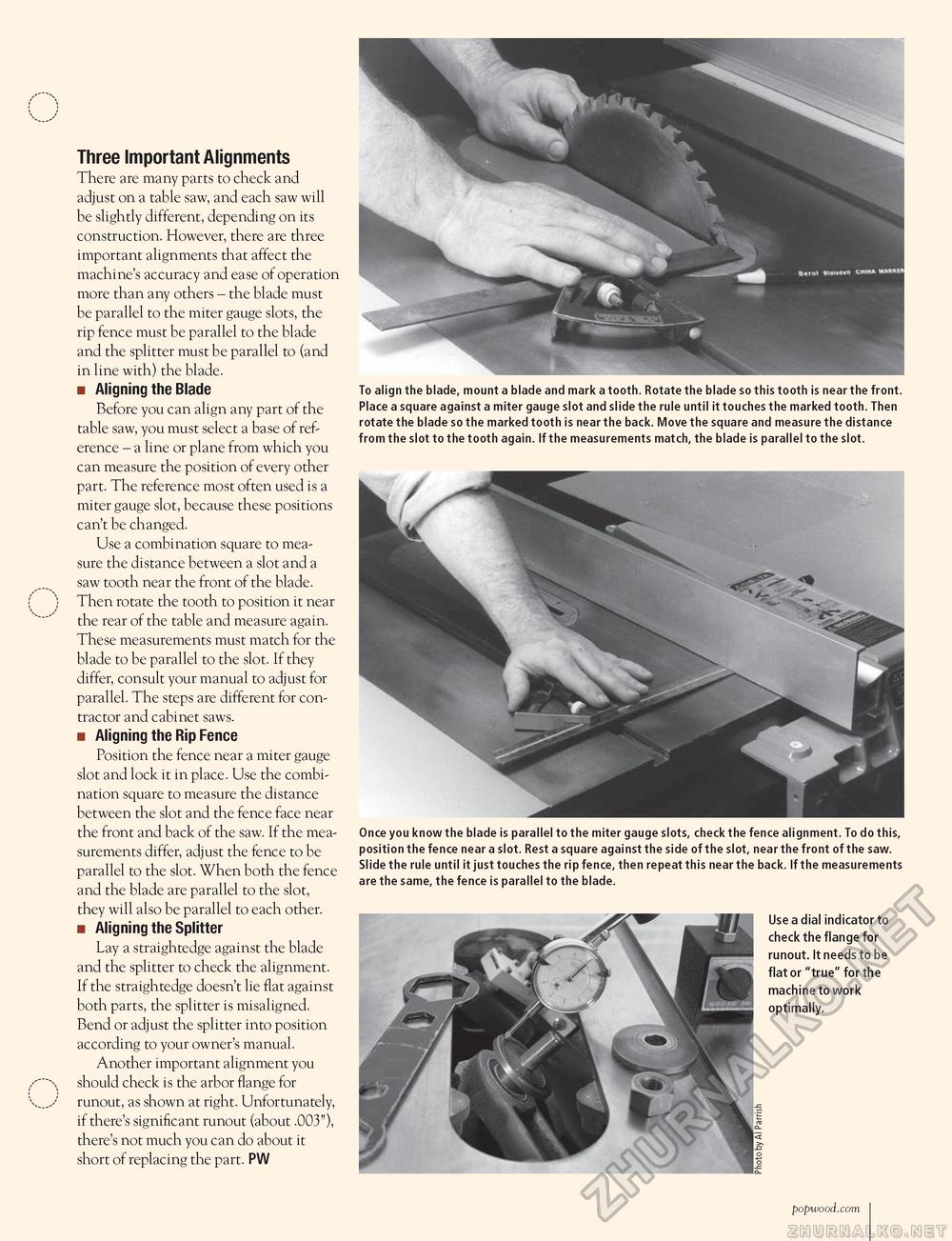

Three Important Alignments There are many parts to check and adjust on a table saw, and each saw will be slightly different, depending on its construction. However, there are three important alignments that affect the machine's accuracy and ease of operation more than any others - the blade must be parallel to the miter gauge slots, the rip fence must be parallel to the blade and the splitter must be parallel to (and in line with) the blade. ■ Aligning the Blade Before you can align any part of the table saw, you must select a base of reference - a line or plane from which you can measure the position of every other part. The reference most often used is a miter gauge slot, because these positions can't be changed. Use a combination square to measure the distance between a slot and a saw tooth near the front of the blade. Then rotate the tooth to position it near the rear of the table and measure again. These measurements must match for the blade to be parallel to the slot. If they differ, consult your manual to adjust for parallel. The steps are different for contractor and cabinet saws. ■ Aligning the Rip Fence Position the fence near a miter gauge slot and lock it in place. Use the combination square to measure the distance between the slot and the fence face near the front and back of the saw. If the measurements differ, adjust the fence to be parallel to the slot. When both the fence and the blade are parallel to the slot, they will also be parallel to each other. ■ Aligning the Splitter Lay a straightedge against the blade and the splitter to check the alignment. If the straightedge doesn't lie flat against both parts, the splitter is misaligned. Bend or adjust the splitter into position according to your owner's manual. Another important alignment you should check is the arbor flange for runout, as shown at right. Unfortunately, if there's significant runout (about .003"), there's not much you can do about it short of replacing the part. PW To align the blade, mount a blade and mark a tooth. Rotate the blade so this tooth is near the front. Place a square against a miter gauge slot and slide the rule until it touches the marked tooth. Then rotate the blade so the marked tooth is near the back. Move the square and measure the distance from the slot to the tooth again. If the measurements match, the blade is parallel to the slot. Once you know the blade is parallel to the miter gauge slots, check the fence alignment. To do this, position the fence near a slot. Rest a square against the side of the slot, near the front of the saw. Slide the rule until it just touches the rip fence, then repeat this near the back. If the measurements are the same, the fence is parallel to the blade. Use a dial indicator to check the flange for runout. It needs to be flat or "true" for the machine to work optimally. popwood.com 62 |