Popular Woodworking 2004-10 № 143, страница 59

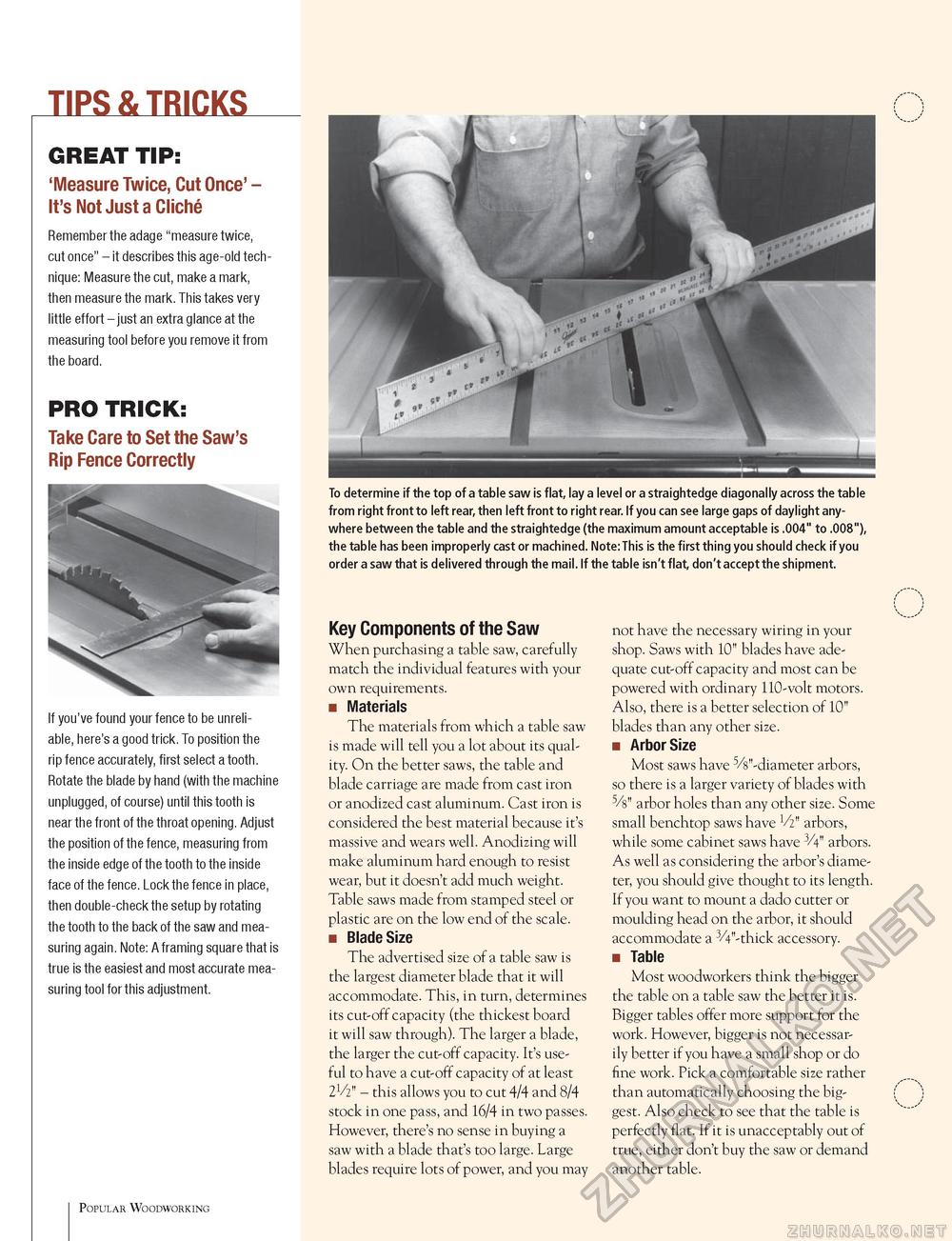

TIPS & TRICKS GREAT TIP: 'Measure Twice, Cut Once' -It's Not Just a Cliche Remember the adage "measure twice, cut once" - it describes this age-old technique: Measure the cut, make a mark, then measure the mark. This takes very little effort - just an extra glance at the measuring tool before you remove it from the board. PRO TRICK: Take Care to Set the Saw's Rip Fence Correctly If you've found your fence to be unreliable, here's a good trick. To position the rip fence accurately, first select a tooth. Rotate the blade by hand (with the machine unplugged, of course) until this tooth is near the front of the throat opening. Adjust the position of the fence, measuring from the inside edge of the tooth to the inside face of the fence. Lock the fence in place, then double-check the setup by rotating the tooth to the back of the saw and measuring again. Note: A framing square that is true is the easiest and most accurate measuring tool for this adjustment. To determine if the top of a table saw is flat, lay a level or a straightedge diagonally across the table from right front to left rear, then left front to right rear. If you can see large gaps of daylight anywhere between the table and the straightedge (the maximum amount acceptable is .004" to .008"), the table has been improperly cast or machined. Note: This is the first thing you should check if you order a saw that is delivered through the mail. If the table isn't flat, don't accept the shipment. Key Components of the Saw When purchasing a table saw, carefully match the individual features with your own requirements. ■ Materials The materials from which a table saw is made will tell you a lot about its quality. On the better saws, the table and blade carriage are made from cast iron or anodized cast aluminum. Cast iron is considered the best material because it's massive and wears well. Anodizing will make aluminum hard enough to resist wear, but it doesn't add much weight. Table saws made from stamped steel or plastic are on the low end of the scale. ■ Blade Size The advertised size of a table saw is the largest diameter blade that it will accommodate. This, in turn, determines its cut-off capacity (the thickest board it will saw through). The larger a blade, the larger the cut-off capacity. It's useful to have a cut-off capacity of at least 21/2" - this allows you to cut 4/4 and 8/4 stock in one pass, and 16/4 in two passes. However, there's no sense in buying a saw with a blade that's too large. Large blades require lots of power, and you may not have the necessary wiring in your shop. Saws with 10" blades have adequate cut-off capacity and most can be powered with ordinary 110-volt motors. Also, there is a better selection of 10" blades than any other size. ■ Arbor Size Most saws have 5/8"-diameter arbors, so there is a larger variety of blades with 5/8" arbor holes than any other size. Some small benchtop saws have arbors, while some cabinet saws have 3/4" arbors. As well as considering the arbor's diameter, you should give thought to its length. If you want to mount a dado cutter or moulding head on the arbor, it should accommodate a 3/4"-thick accessory. ■ Table Most woodworkers think the bigger the table on a table saw the better it is. Bigger tables offer more support for the work. However, bigger is not necessarily better if you have a small shop or do fine work. Pick a comfortable size rather than automatically choosing the biggest. Also check to see that the table is perfectly flat. If it is unacceptably out of true, either don't buy the saw or demand another table. Popular Woodworking |