Popular Woodworking 2004-11 № 144, страница 104

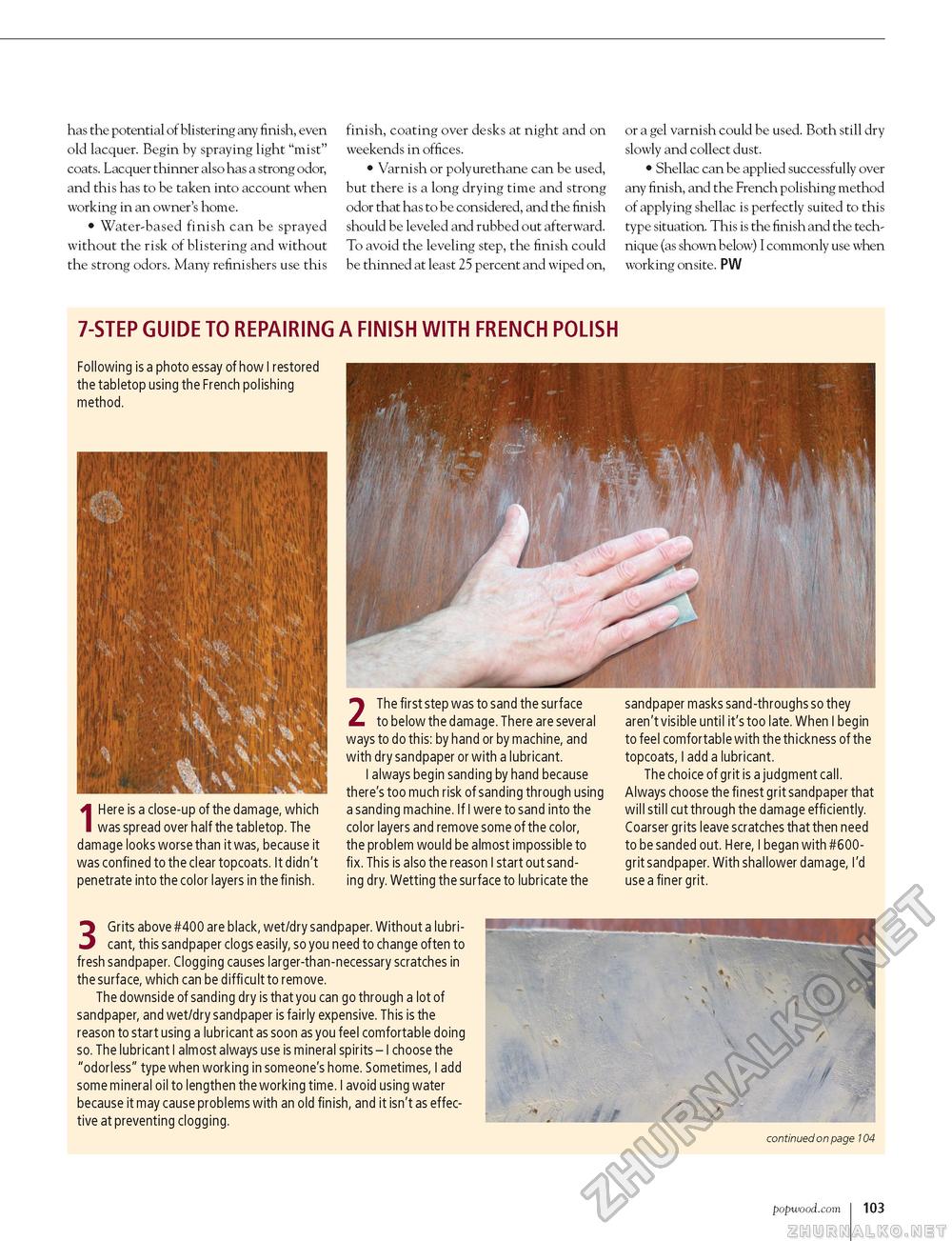

has the potential of blistering any finish, even old lacquer. Begin by spraying light "mist" coats. Lacquer thinner also has a strong odor, and this has to be taken into account when working in an owner's home. • Water-based finish can be sprayed without the risk of blistering and without the strong odors. Many refinishers use this finish, coating over desks at night and on weekends in offices. • Varnish or polyurethane can be used, but there is a long drying time and strong odor that has to be considered, and the finish should be leveled and rubbed out afterward. To avoid the leveling step, the finish could be thinned at least 25 percent and wiped on, or a gel varnish could be used. Both still dry slowly and collect dust. • Shellac can be applied successfully over any finish, and the French polishing method of applying shellac is perfectly suited to this type situation. This is the finish and the technique (as shown below) I commonly use when working onsite. PW 7-STEP GUIDE TO REPAIRING A FINISH WITH FRENCH POLISH Following is a photo essay of how I restored the tabletop using the French polishing method. 2 The first step was to sand the surface to below the damage. There are several ways to do this: by hand or by machine, and with dry sandpaper or with a lubricant. I always begin sanding by hand because there's too much risk of sanding through using a sanding machine. If I were to sand into the color layers and remove some of the color, the problem would be almost impossible to fix. This is also the reason I start out sanding dry. Wetting the surface to lubricate the sandpaper masks sand-throughs so they aren't visible until it's too late. When I begin to feel comfortable with the thickness of the topcoats, I add a lubricant. The choice of grit is a judgment call. Always choose the finest grit sandpaper that will still cut through the damage efficiently. Coarser grits leave scratches that then need to be sanded out. Here, I began with #600-grit sandpaper. With shallower damage, I'd use a finer grit. continued on page 104 IHere is a close-up of the damage, which was spread over half the tabletop. The damage looks worse than it was, because it was confined to the clear topcoats. It didn't penetrate into the color layers in the finish. 3 Grits above #400 are black, wet/dry sandpaper. Without a lubricant, this sandpaper clogs easily, so you need to change often to fresh sandpaper. Clogging causes larger-than-necessary scratches in the surface, which can be difficult to remove. The downside of sanding dry is that you can go through a lot of sandpaper, and wet/dry sandpaper is fairly expensive. This is the reason to start using a lubricant as soon as you feel comfortable doing so. The lubricant I almost always use is mineral spirits - I choose the "odorless" type when working in someone's home. Sometimes, I add some mineral oil to lengthen the working time. I avoid using water because it may cause problems with an old finish, and it isn't as effective at preventing clogging. popwood.com 103 |