Popular Woodworking 2004-11 № 144, страница 73

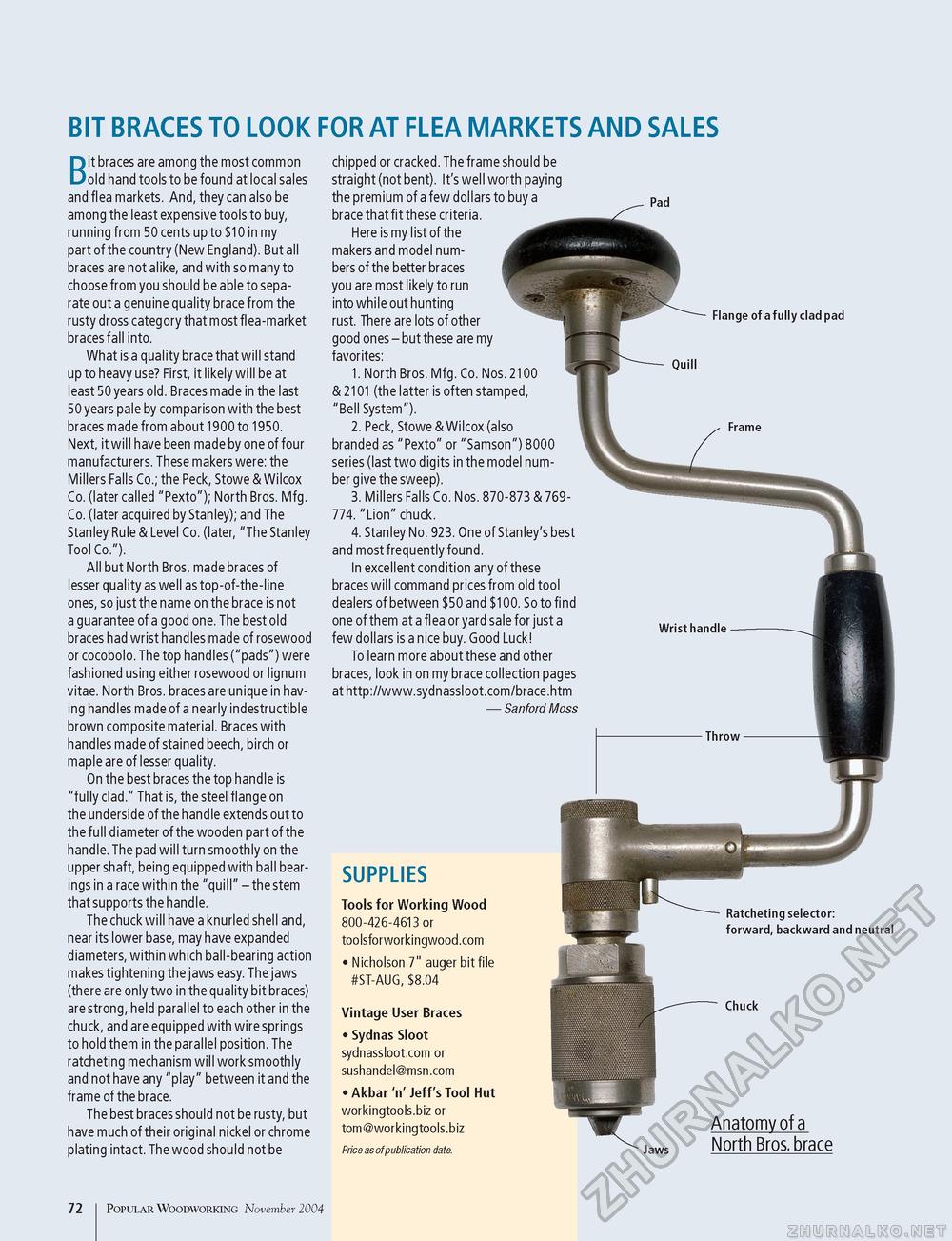

BIT BRACES TO LOOK FOR AT FLEA MARKETS AND SALES Bit braces are among the most common old hand tools to be found at local sales and flea markets. And, they can also be among the least expensive tools to buy, running from 50 cents up to $10 in my part of the country (New England). But all braces are not alike, and with so many to choose from you should be able to separate out a genuine quality brace from the rusty dross category that most flea-market braces fall into. What is a quality brace that will stand up to heavy use? First, it likely will be at least 50 years old. Braces made in the last 50 years pale by comparison with the best braces made from about 1900 to 1950. Next, it will have been made by one of four manufacturers. These makers were: the Millers Falls Co.; the Peck, Stowe & Wilcox Co. (later called "Pexto"); North Bros. Mfg. Co. (later acquired by Stanley); and The Stanley Rule & Level Co. (later, "The Stanley Tool Co."). All but North Bros. made braces of lesser quality as well as top-of-the-line ones, so just the name on the brace is not a guarantee of a good one. The best old braces had wrist handles made of rosewood or cocobolo. The top handles ("pads") were fashioned using either rosewood or lignum vitae. North Bros. braces are unique in having handles made of a nearly indestructible brown composite material. Braces with handles made of stained beech, birch or maple are of lesser quality. On the best braces the top handle is "fully clad." That is, the steel flange on the underside of the handle extends out to the full diameter of the wooden part of the handle. The pad will turn smoothly on the upper shaft, being equipped with ball bearings in a race within the "quill" - the stem that supports the handle. The chuck will have a knurled shell and, near its lower base, may have expanded diameters, within which ball-bearing action makes tightening the jaws easy. The jaws (there are only two in the quality bit braces) are strong, held parallel to each other in the chuck, and are equipped with wire springs to hold them in the parallel position. The ratcheting mechanism will work smoothly and not have any "play" between it and the frame of the brace. The best braces should not be rusty, but have much of their original nickel or chrome plating intact. The wood should not be chipped or cracked. The frame should be straight (not bent). It's well worth paying the premium of a few dollars to buy a brace that fit these criteria. Here is my list of the makers and model numbers of the better braces you are most likely to run into while out hunting rust. There are lots of other good ones - but these are my favorites: 1. North Bros. Mfg. Co. Nos. 2100 & 2101 (the latter is often stamped, "Bell System"). 2. Peck, Stowe & Wilcox (also branded as "Pexto" or "Samson") 8000 series (last two digits in the model number give the sweep). 3. Millers Falls Co. Nos. 870-873 & 769774. "Lion" chuck. 4. Stanley No. 923. One of Stanley's best and most frequently found. In excellent condition any of these braces will command prices from old tool dealers of between $50 and $100. So to find one of them at a flea or yard sale for just a few dollars is a nice buy. Good Luck! To learn more about these and other braces, look in on my brace collection pages at http://www.sydnassloot.com/brace.htm — Sanford Moss Flange of a fully clad pad SUPPLIES Tools for Working Wood 800-426-4613 or toolsforworkingwood.com • Nicholson 7" auger bit file #ST-AUG, $8.04 Vintage User Braces • Sydnas Sloot sydnassloot.com or sushandel@msn.com • Akbar 'n' Jeff's Tool Hut workingtools.biz or tom@workingtools.biz Price as of publication date. Ratcheting selector: forward, backward and neutral Anatomy of a Jaws North Bros. brace 72 Popular Woodworking November 2004 |