Popular Woodworking 2004-11 № 144, страница 71

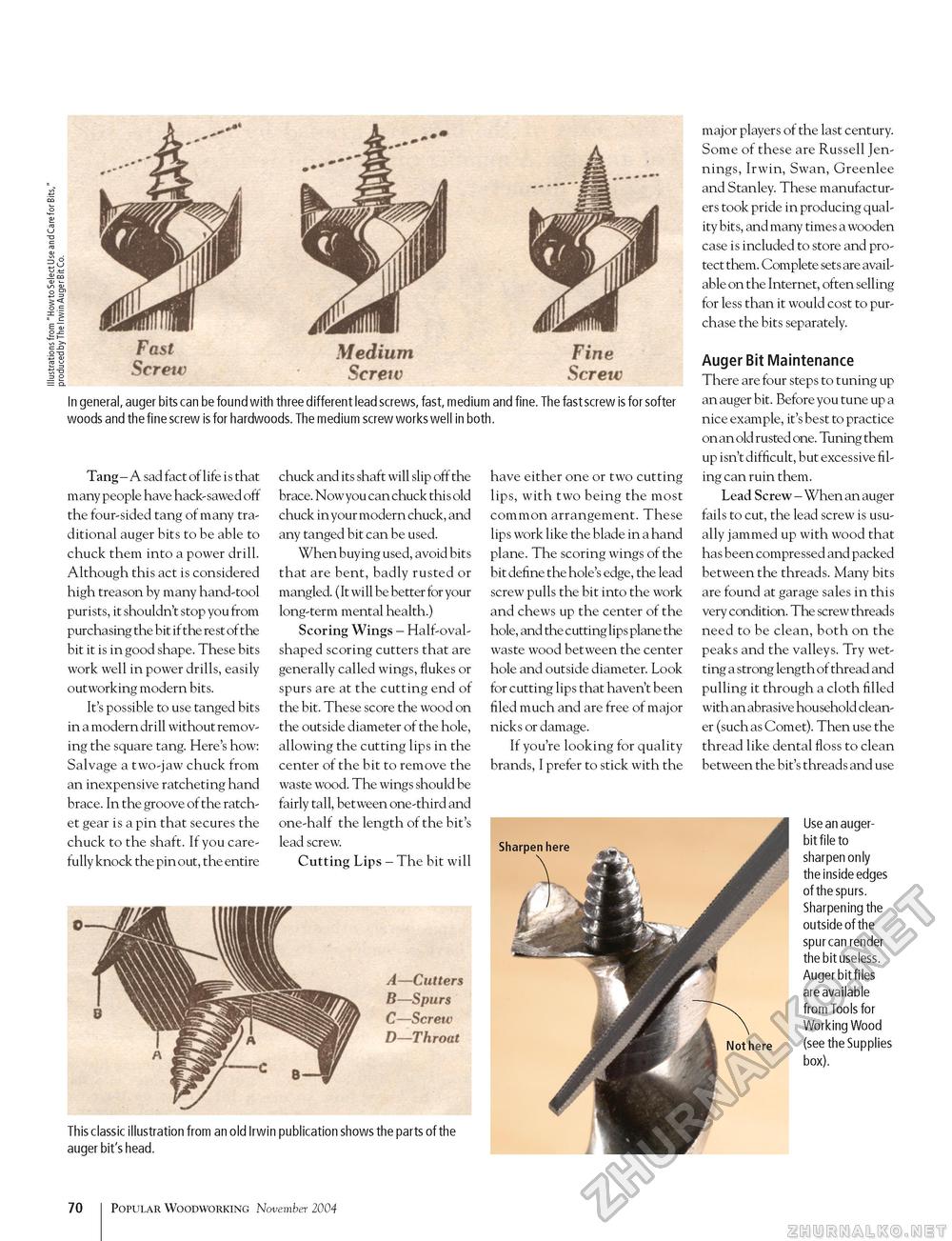

Fast Screiv Medium Screw Fine Screiv In general, auger bits can be found with three different lead screws, fast, medium and fine. The fast screw is for softer woods and the fine screw is for hardwoods. The medium screw works well in both. Tang - A sad fact of life i s that many people have hack-sawed off the four-sided tang of many traditional auger bits to be able to chuck them into a power drill. Although this act is considered high treason by many hand-tool purists, it shouldn't stop you from purchasing the bit if the rest of the bit it is in good shape. These bits work well in power drills, easily outworking modern bits. It's possible to use tanged bits in a modern drill without removing the square tang. Here's how: Salvage a two-jaw chuck from an inexpensive ratcheting hand brace. In the groove of the ratchet gear is a pin that secures the chuck to the shaft. If you carefully knock the pin out, the entire chuck and its shaft will slip off the brace. Now you can chuck this old chuck in your modern chuck, and any tanged bit can be used. When buying used, avoid bits that are bent, badly rusted or mangled. (It will be better for your long-term mental health.) Scoring Wings - Half-oval-shaped scoring cutters that are generally called wings, flukes or spurs are at the cutting end of the bit. These score the wood on the outside diameter of the hole, allowing the cutting lips in the center of the bit to remove the waste wood. The wings should be fairly tall, between one-third and one-half the length of the bit's lead screw. Cutting Lips - The bit will have either one or two cutting lips, with two being the most common arrangement. These lips work like the blade in a hand plane. The scoring wings of the bit define the hole's edge, the lead screw pulls the bit into the work and chews up the center of the hole, and the cutting lips plane the waste wood between the center hole and outside diameter. Look for cutting lips that haven't been filed much and are free of major nicks or damage. If you're looking for quality brands, I prefer to stick with the Sharpen here This classic illustration from an old Irwin publication shows the parts of the auger bit's head. major players of the last century. Some of these are Russell Jennings, Irwin, Swan, Greenlee and Stanley. These manufacturers took pride in producing quality bits, and many times a wooden case is included to store and protect them. Complete sets are available on the Internet, often selling for less than it would cost to purchase the bits separately. Auger Bit Maintenance There are four steps to tuning up an auger bit. Before you tune up a nice example, it's best to practice on an old rusted one. Tuning them up isn't difficult, but excessive filing can ruin them. Lead Screw - When an auger fails to cut, the lead screw is usually jammed up with wood that has been compressed and packed between the threads. Many bits are found at garage sales in this very condition. The screw threads need to be clean, both on the peaks and the valleys. Try wetting a strong length of thread and pulling it through a cloth filled with an abrasive household cleaner (such as Comet). Then use the thread like dental floss to clean between the bit's threads and use Use an auger-bit file to sharpen only the inside edges of the spurs. Sharpening the outside of the spur can render the bit useless. Auger bit files are available from Tools for Working Wood (see the Supplies box). Not here 70 Popular Woodworking November 2004 |