Popular Woodworking 2004-11 № 144, страница 69

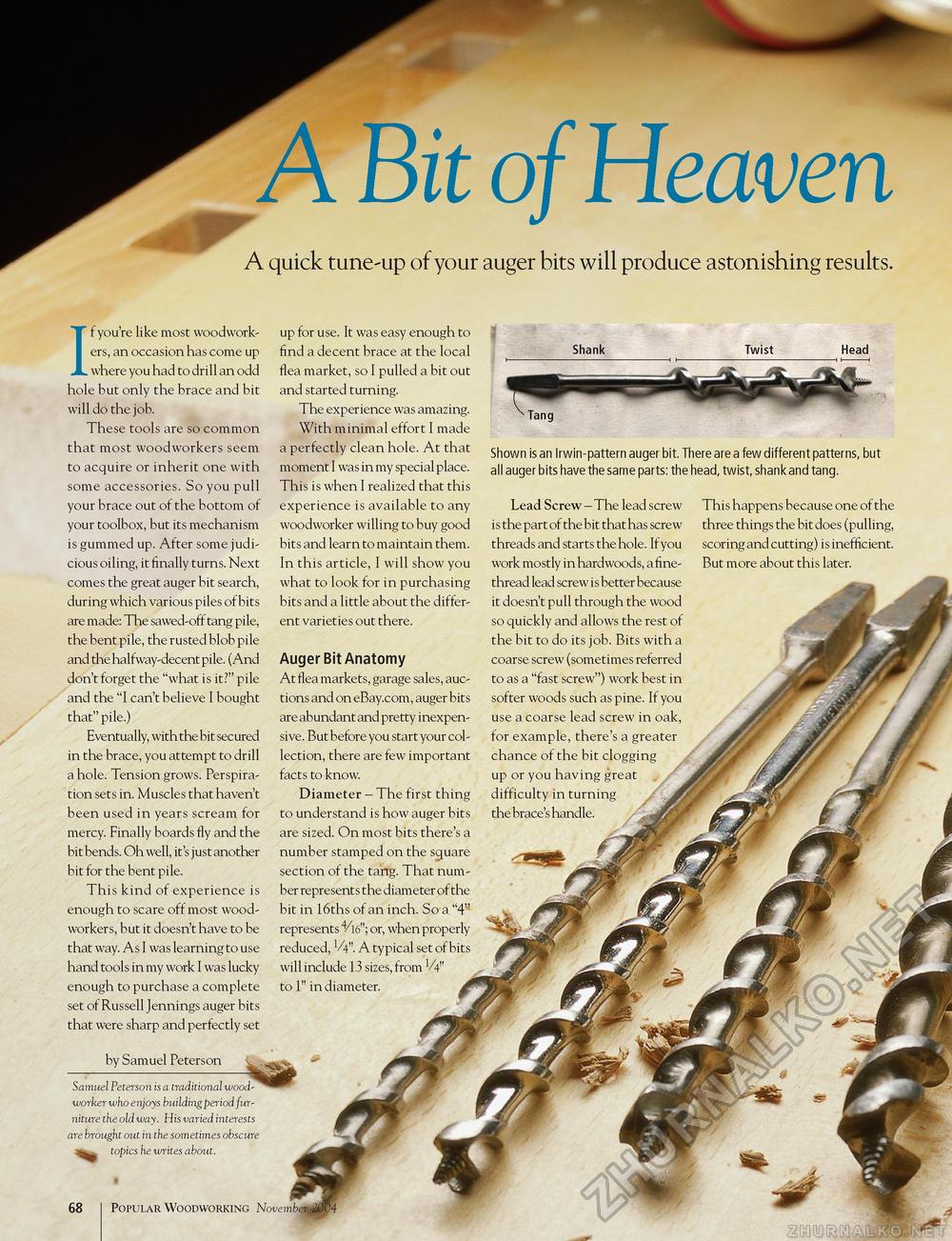

If you're like most woodworkers, an occasion has come up where you had to drill an odd hole but only the brace and bit will do the job. These tools are so common that most woodworkers seem to acquire or inherit one with some accessories. So you pull your brace out of the bottom of your toolbox, but its mechanism is gummed up. After some judicious oiling, it finally turns. Next comes the great auger bit search, during which various piles of bits are made: The sawed-off tang pile, the bent pile, the rusted blob pile and the halfway-decent pile. (And don't forget the "what is it?" pile and the "I can't believe I bought that" pile.) Eventually, with the bit secured in the brace, you attempt to drill a hole. Tension grows. Perspiration sets in. Muscles that haven't been used in years scream for mercy. Finally boards fly and the bit bends. Oh well, it's just another bit for the bent pile. This kind of experience is enough to scare off most woodworkers, but it doesn't have to be that way. As I was learning to use hand tools in my work I was lucky enough to purchase a complete set of Russell Jennings auger bits that were sharp and perfectly set by Samuel Peterson Samuel Peterson is a traditional woodworker who enjoys building period furniture the old way. His varied interests are brought out in the sometimes obscure topics he writes about. up for use. It was easy enough to find a decent brace at the local flea market, so I pulled a bit out and started turning. The experience was amazing. With minimal effort I made a perfectly clean hole. At that moment I was in my special place. This is when I realized that this experience is available to any woodworker willing to buy good bits and learn to maintain them. In this article, I will show you what to look for in purchasing bits and a little about the different varieties out there. Auger Bit Anatomy At flea markets, garage sales, auctions and on eBay.com, auger bits are abundant and pretty inexpensive. But before you start your collection, there are few important facts to know. Diameter - The first thing to understand is how auger bits are sized. On most bits there's a number stamped on the square section of the tang. That number represents the diameter of the bit in 16ths of an inch. So a "4" represents 4/16"; or, when properly reduced, VV" A typical set of bits will include 13 sizes, from V4" to 1" in diameter. Shown is an Irwin-pattern auger bit. There are a few different patterns, but all auger bits have the same parts: the head, twist, shank and tang. Lead Screw - The lead screw is the part of the bit that has screw threads and starts the hole. If you work mostly in hardwoods, a fine-thread lead screw is better because it doesn't pull through the wood so quickly and allows the rest of the bit to do its job. Bits with a coarse screw (sometimes referred to as a "fast screw") work best in softer woods such as pine. If you use a coarse lead screw in oak, for example, there's a greater chance of the bit clogging up or you having great difficulty in turning the brace's handle. This happens because one of the three things the bit does (pulling, scoring and cutting) is inefficient. But more about this later. 68 Popular Woodworking November 2004 |