Popular Woodworking 2004-11 № 144, страница 86

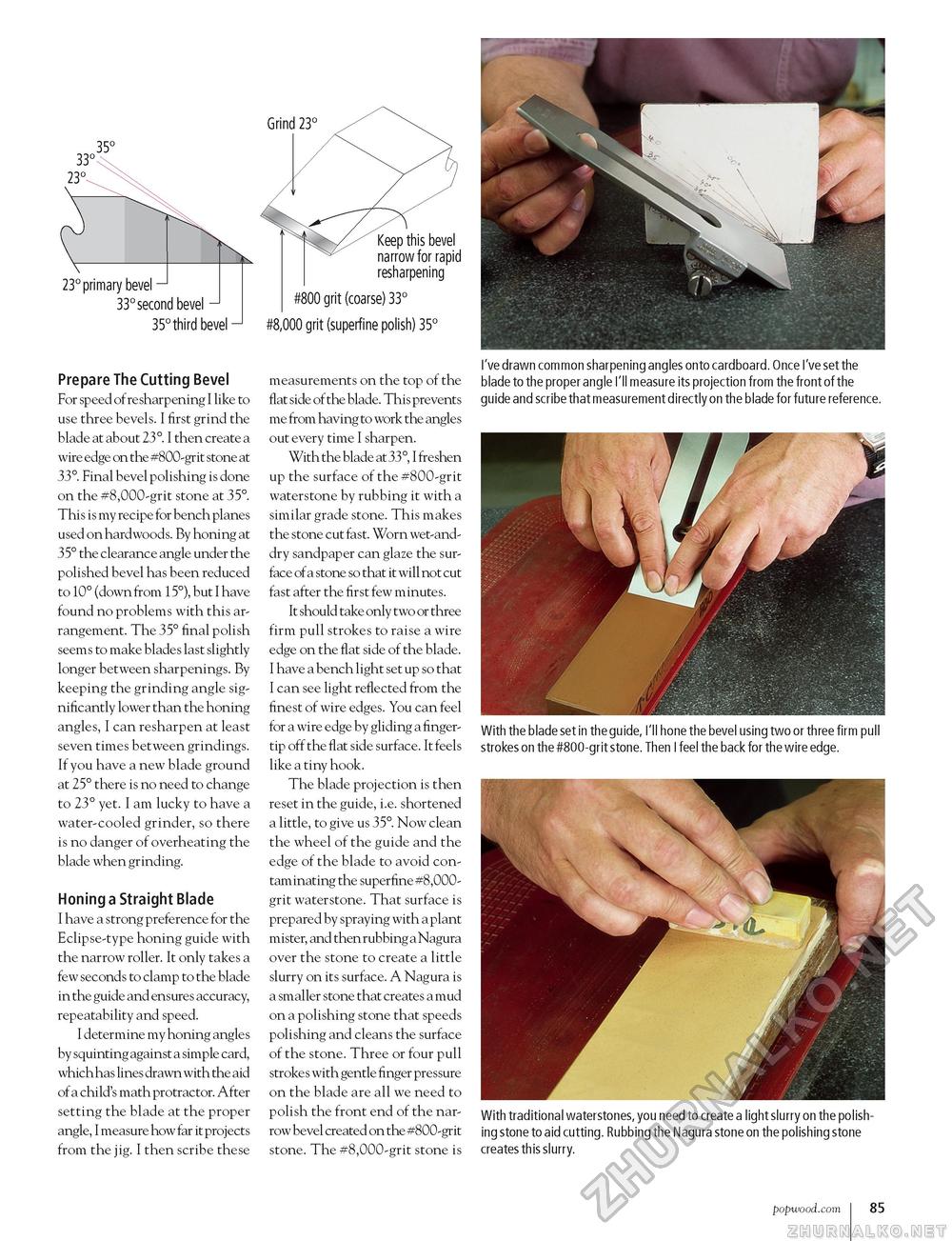

Prepare The Cutting Bevel For speed of resharpening I like to use three bevels. I first grind the blade at about 23°. I then create a wire edge on the #800-grit stone at 33°. Final bevel polishing is done on the #8,000-grit stone at 35°. This is my recipe for bench planes used on hardwoods. By honing at 35° the clearance angle under the polished bevel has been reduced to 10° (down from 15°), but I have found no problems with this arrangement. The 35° final polish seems to make blades last slightly longer between sharpenings. By keeping the grinding angle significantly lower than the honing angles, I can resharpen at least seven times between grindings. If you have a new blade ground at 25° there is no need to change to 23° yet. I am lucky to have a water-cooled grinder, so there is no danger of overheating the blade when grinding. Honing a Straight Blade I have a strong preference for the Eclipse-type honing guide with the narrow roller. It only takes a few seconds to clamp to the blade in the guide and ensures accuracy, repeatability and speed. I determine my honing angles by squinting against a simple card, which has lines drawn with the aid of a child's math protractor. After setting the blade at the proper angle, I measure how far it projects from the jig. I then scribe these #800 grit (coarse) 33° #8,000 grit (superfine polish) 35° measurements on the top of the flat side of the blade. This prevents me from having to work the angles out every time I sharpen. With the blade at 33°, I freshen up the surface of the #800-grit waterstone by rubbing it with a similar grade stone. This makes the stone cut fast. Worn wet-and-dry sandpaper can glaze the surface of a stone so that it will not cut fast after the first few minutes. It should take only two or three firm pull strokes to raise a wire edge on the flat side of the blade. I have a bench light set up so that I can see light reflected from the finest of wire edges. You can feel for a wire edge by gliding a fingertip off the flat side surface. It feels like a tiny hook. The blade projection is then reset in the guide, i.e. shortened a little, to give us 35°. Now clean the wheel of the guide and the edge of the blade to avoid contaminating the superfine #8,000-grit waterstone. That surface is prepared by spraying with a plant mister, and then rubbing a Nagura over the stone to create a little slurry on its surface. A Nagura is a smaller stone that creates a mud on a polishing stone that speeds polishing and cleans the surface of the stone. Three or four pull strokes with gentle finger pressure on the blade are all we need to polish the front end of the narrow bevel created on the #800-grit stone. The #8,000-grit stone is I've drawn common sharpening angles onto cardboard. Once I've set the blade to the proper angle I'll measure its projection from the front of the guide and scribe that measurement directly on the blade for future reference. With traditional waterstones, you need to create a light slurry on the polishing stone to aid cutting. Rubbing the Nagura stone on the polishing stone creates this slurry. popwood.com 85 |