Popular Woodworking 2004-11 № 144, страница 97

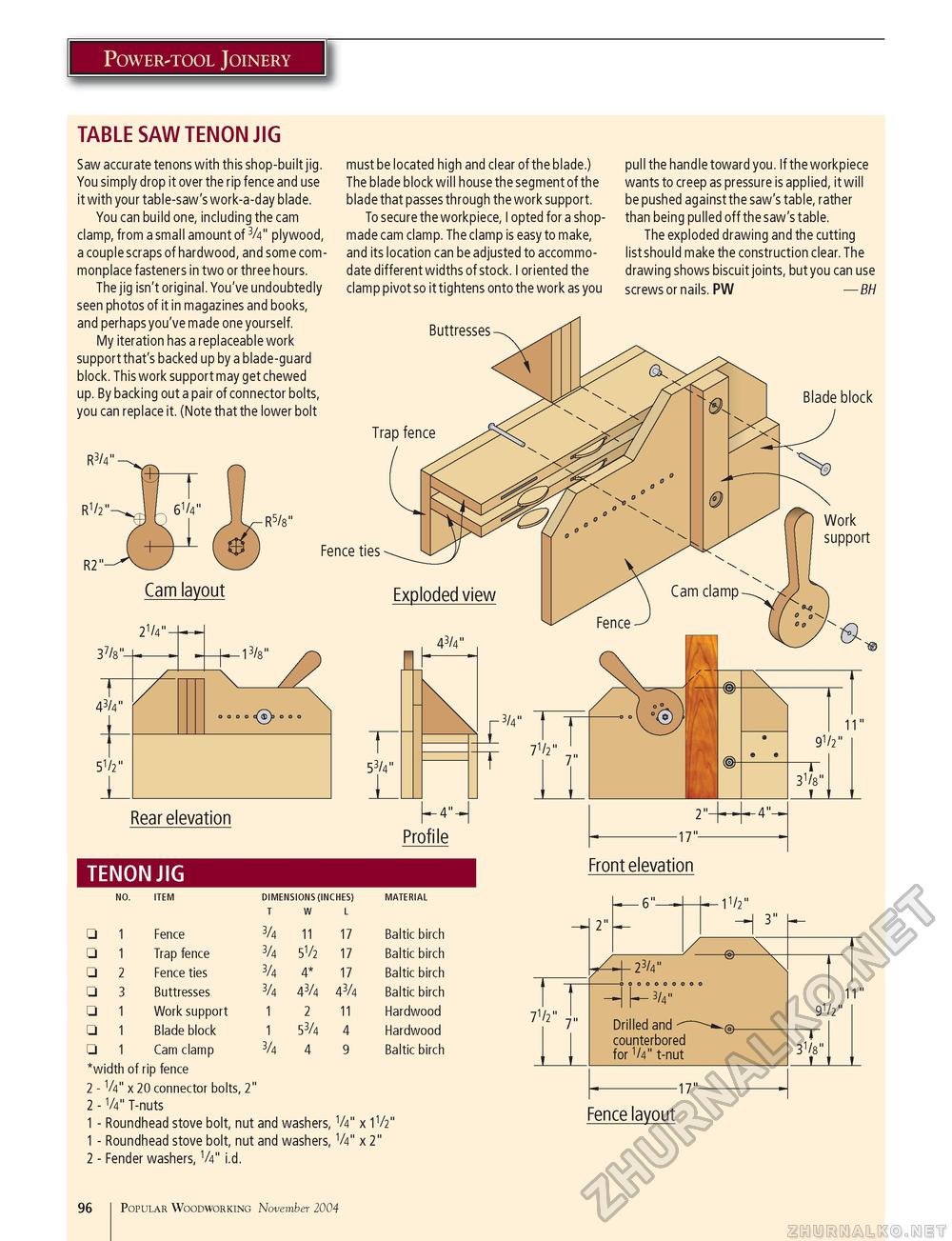

Power-tool Joinery TABLE SAW TENON JIG Saw accurate tenons with this shop-built jig. You simply drop it over the rip fence and use it with your table-saw's work-a-day blade. You can build one, including the cam clamp, from a small amount of 3/4" plywood, a couple scraps of hardwood, and some commonplace fasteners in two or three hours. The jig isn't original. You've undoubtedly seen photos of it in magazines and books, and perhaps you've made one yourself. My iteration has a replaceable work support that's backed up by a blade-guard block. This work support may get chewed up. By backing out a pair of connector bolts, you can replace it. (Note that the lower bolt must be located high and clear of the blade.) The blade block will house the segment of the blade that passes through the work support. To secure the workpiece, I opted for a shop-made cam clamp. The clamp is easy to make, and its location can be adjusted to accommodate different widths of stock. I oriented the clamp pivot so it tightens onto the work as you Buttresses pull the handle toward you. If the workpiece wants to creep as pressure is applied, it will be pushed against the saw's table, rather than being pulled off the saw's table. The exploded drawing and the cutting list should make the construction clear. The drawing shows biscuit joints, but you can use screws or nails. PW — BH Blade block R5/8" Fence ties Cam layout Rear elevation TENON JIG □ 1 Fence □ 1 Trap fence □ 2 Fence ties □ 3 Buttresses □ 1 Work support □ 1 Blade block □ 1 Cam clamp *width of rip fence 2 - V4" x 20 connector bolts, 2" 2 - V4" T-nuts 1 - Roundhead stove bolt, nut and washers, V4" x 1 - Roundhead stove bolt, nut and washers, V4" x 2 - Fender washers, V4" i.d. Front elevation

7V2" ,,, 2" -6"- -1V2" -i 3" -23/4" 000000000 I— 3/4" Drilled and counterbored for V4" t-nut -17"- 11' 9V2" 3V8" t 1V2" 2" Fence layout NO ITEM 96 Popular Woodworking November 2004 |

||||||||||||||||||||||||||||||||||||