Popular Woodworking 2005-02 № 146, страница 58

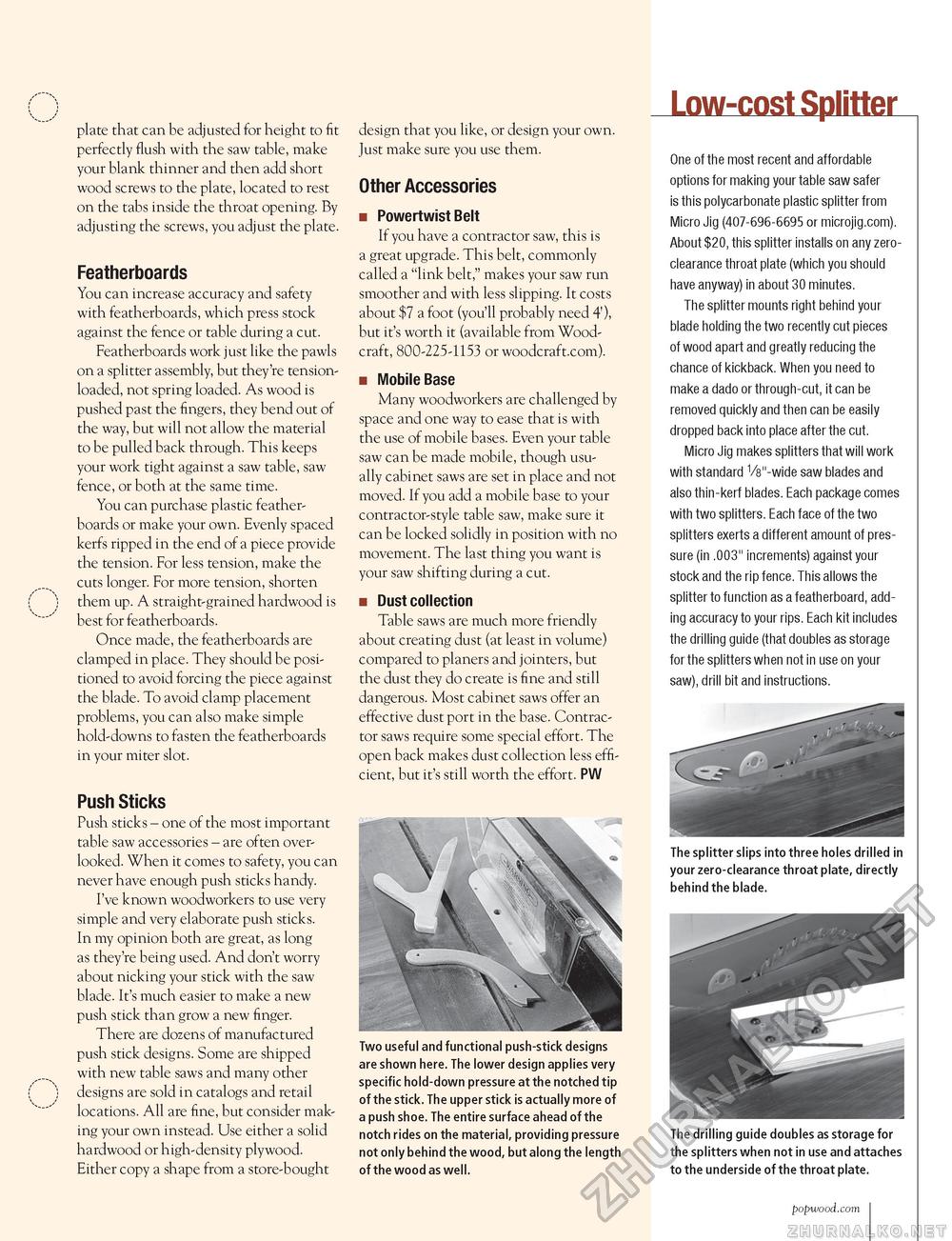

plate that can be adjusted for height to fit perfectly flush with the saw table, make your blank thinner and then add short wood screws to the plate, located to rest on the tabs inside the throat opening. By adjusting the screws, you adjust the plate. Featherboards You can increase accuracy and safety with featherboards, which press stock against the fence or table during a cut. Featherboards work just like the pawls on a splitter assembly, but they're tension-loaded, not spring loaded. As wood is pushed past the fingers, they bend out of the way, but will not allow the material to be pulled back through. This keeps your work tight against a saw table, saw fence, or both at the same time. You can purchase plastic feather-boards or make your own. Evenly spaced kerfs ripped in the end of a piece provide the tension. For less tension, make the cuts longer. For more tension, shorten them up. A straight-grained hardwood is best for featherboards. Once made, the featherboards are clamped in place. They should be positioned to avoid forcing the piece against the blade. To avoid clamp placement problems, you can also make simple hold-downs to fasten the featherboards in your miter slot. Push Sticks Push sticks - one of the most important table saw accessories - are often overlooked. When it comes to safety, you can never have enough push sticks handy. I've known woodworkers to use very simple and very elaborate push sticks. In my opinion both are great, as long as they're being used. And don't worry about nicking your stick with the saw blade. It's much easier to make a new push stick than grow a new finger. There are dozens of manufactured push stick designs. Some are shipped with new table saws and many other designs are sold in catalogs and retail locations. All are fine, but consider making your own instead. Use either a solid hardwood or high-density plywood. Either copy a shape from a store-bought design that you like, or design your own. Just make sure you use them. Other Accessories ■ Powertwist Belt If you have a contractor saw, this is a great upgrade. This belt, commonly called a "link belt," makes your saw run smoother and with less slipping. It costs about $7 a foot (you'll probably need 4'), but it's worth it (available from Woodcraft, 800-225-1153 or woodcraft.com). ■ Mobile Base Many woodworkers are challenged by space and one way to ease that is with the use of mobile bases. Even your table saw can be made mobile, though usually cabinet saws are set in place and not moved. If you add a mobile base to your contractor-style table saw, make sure it can be locked solidly in position with no movement. The last thing you want is your saw shifting during a cut. ■ Dust collection Table saws are much more friendly about creating dust (at least in volume) compared to planers and jointers, but the dust they do create is fine and still dangerous. Most cabinet saws offer an effective dust port in the base. Contractor saws require some special effort. The open back makes dust collection less efficient, but it's still worth the effort. PW Two useful and functional push-stick designs are shown here. The lower design applies very specific hold-down pressure at the notched tip of the stick. The upper stick is actually more of a push shoe. The entire surface ahead of the notch rides on the material, providing pressure not only behind the wood, but along the length of the wood as well. Low-cost Splitter One of the most recent and affordable options for making your table saw safer is this polycarbonate plastic splitter from Micro Jig (407-696-6695 or microjig.com). About $20, this splitter installs on any zero-clearance throat plate (which you should have anyway) in about 30 minutes. The splitter mounts right behind your blade holding the two recently cut pieces of wood apart and greatly reducing the chance of kickback. When you need to make a dado or through-cut, it can be removed quickly and then can be easily dropped back into place after the cut. Micro Jig makes splitters that will work with standard V8"-wide saw blades and also thin-kerf blades. Each package comes with two splitters. Each face of the two splitters exerts a different amount of pressure (in .003" increments) against your stock and the rip fence. This allows the splitter to function as a featherboard, adding accuracy to your rips. Each kit includes the drilling guide (that doubles as storage for the splitters when not in use on your saw), drill bit and instructions. The splitter slips into three holes drilled in your zero-clearance throat plate, directly behind the blade. The drilling guide doubles as storage for the splitters when not in use and attaches to the underside of the throat plate. popwood.com 58 |