Popular Woodworking 2005-02 № 146, страница 56

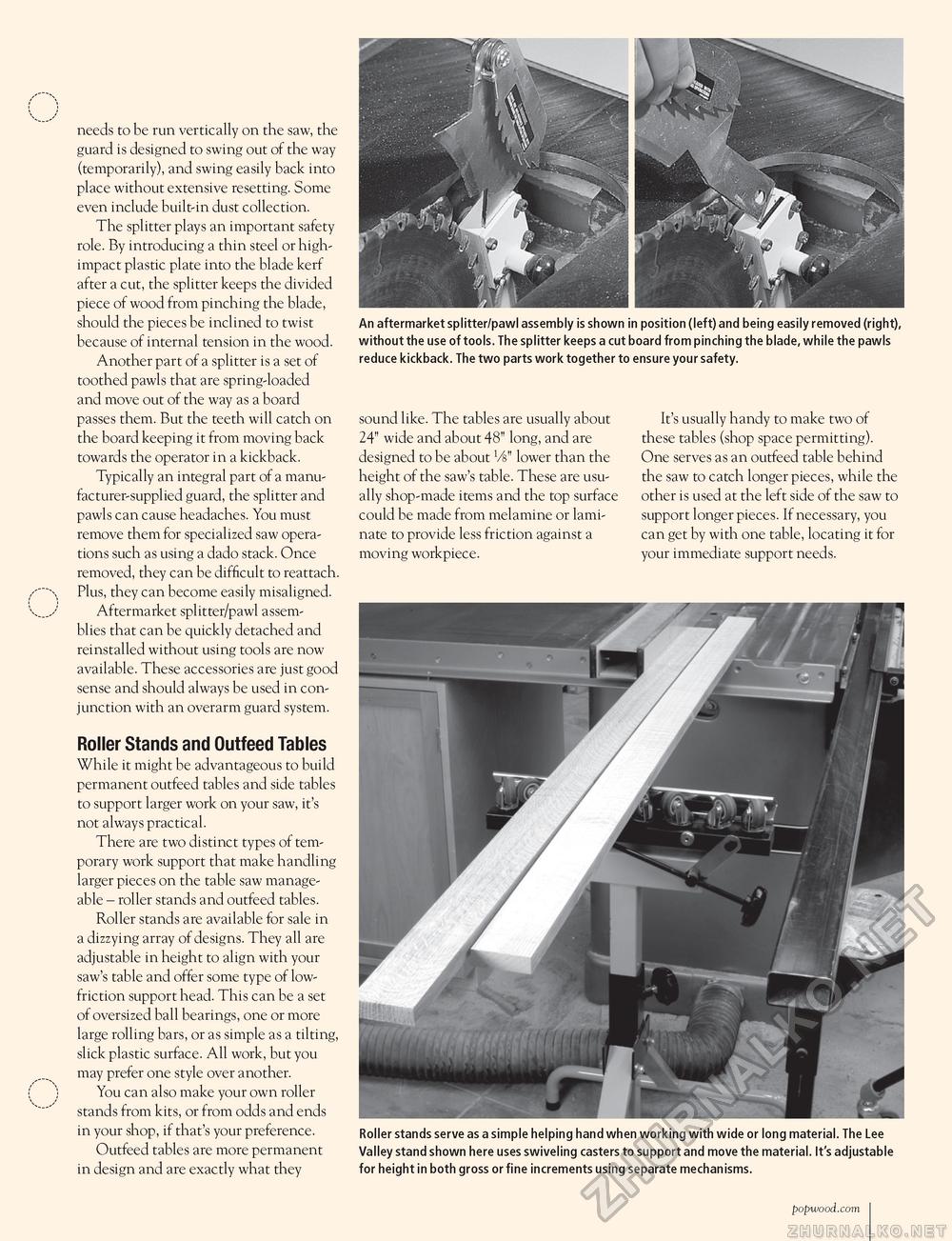

needs to be run vertically on the saw, the guard is designed to swing out of the way (temporarily), and swing easily back into place without extensive resetting. Some even include built-in dust collection. The splitter plays an important safety role. By introducing a thin steel or high-impact plastic plate into the blade kerf after a cut, the splitter keeps the divided piece of wood from pinching the blade, should the pieces be inclined to twist because of internal tension in the wood. Another part of a splitter is a set of toothed pawls that are spring-loaded and move out of the way as a board passes them. But the teeth will catch on the board keeping it from moving back towards the operator in a kickback. Typically an integral part of a manufacturer-supplied guard, the splitter and pawls can cause headaches. You must remove them for specialized saw operations such as using a dado stack. Once removed, they can be difficult to reattach. Plus, they can become easily misaligned. Aftermarket splitter/pawl assemblies that can be quickly detached and reinstalled without using tools are now available. These accessories are just good sense and should always be used in conjunction with an overarm guard system. Roller Stands and Outfeed Tables While it might be advantageous to build permanent outfeed tables and side tables to support larger work on your saw, it's not always practical. There are two distinct types of temporary work support that make handling larger pieces on the table saw manageable - roller stands and outfeed tables. Roller stands are available for sale in a dizzying array of designs. They all are adjustable in height to align with your saw's table and offer some type of low-friction support head. This can be a set of oversized ball bearings, one or more large rolling bars, or as simple as a tilting, slick plastic surface. All work, but you may prefer one style over another. You can also make your own roller stands from kits, or from odds and ends in your shop, if that's your preference. Outfeed tables are more permanent in design and are exactly what they An aftermarket splitter/pawl assembly is shown in position (left) and being easily removed (right), without the use of tools. The splitter keeps a cut board from pinching the blade, while the pawls reduce kickback. The two parts work together to ensure your safety. sound like. The tables are usually about 24" wide and about 48" long, and are designed to be about V8" lower than the height of the saw's table. These are usually shop-made items and the top surface could be made from melamine or laminate to provide less friction against a moving workpiece. It's usually handy to make two of these tables (shop space permitting). One serves as an outfeed table behind the saw to catch longer pieces, while the other is used at the left side of the saw to support longer pieces. If necessary, you can get by with one table, locating it for your immediate support needs. Roller stands serve as a simple helping hand when working with wide or long material. The Lee Valley stand shown here uses swiveling casters to support and move the material. It's adjustable for height in both gross or fine increments using separate mechanisms. popwood.com 56 |