Popular Woodworking 2005-02 № 146, страница 54

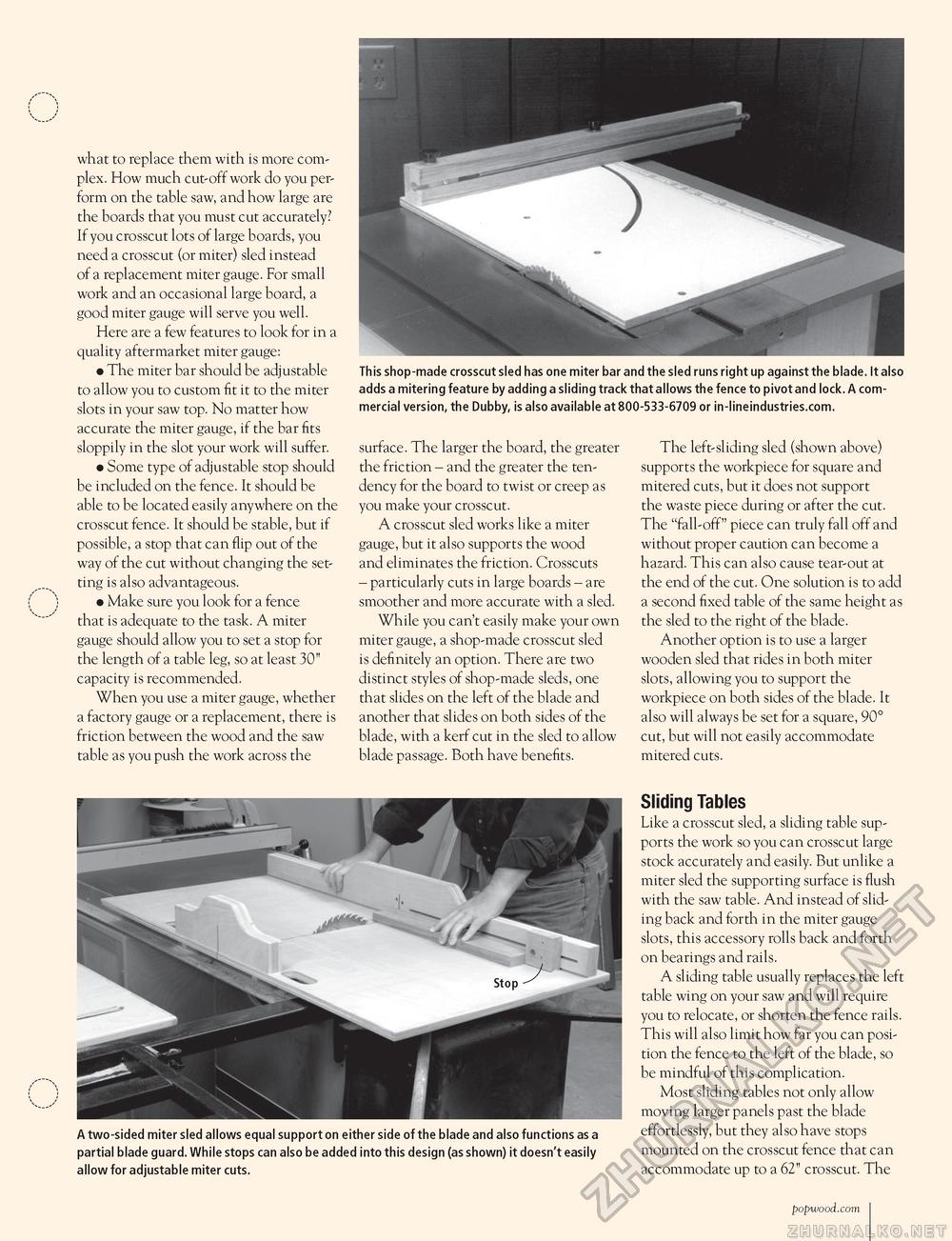

This shop-made crosscut sled has one miter bar and the sled runs right up against the blade. It also adds a mitering feature by adding a sliding track that allows the fence to pivot and lock. A commercial version, the Dubby, is also available at 800-533-6709 or in-lineindustries.com. what to replace them with is more complex. How much cut-off work do you perform on the table saw, and how large are the boards that you must cut accurately? If you crosscut lots of large boards, you need a crosscut (or miter) sled instead of a replacement miter gauge. For small work and an occasional large board, a good miter gauge will serve you well. Here are a few features to look for in a quality aftermarket miter gauge: • The miter bar should be adjustable to allow you to custom fit it to the miter slots in your saw top. No matter how accurate the miter gauge, if the bar fits sloppily in the slot your work will suffer. • Some type of adjustable stop should be included on the fence. It should be able to be located easily anywhere on the crosscut fence. It should be stable, but if possible, a stop that can flip out of the way of the cut without changing the setting is also advantageous. • Make sure you look for a fence that is adequate to the task. A miter gauge should allow you to set a stop for the length of a table leg, so at least 30" capacity is recommended. When you use a miter gauge, whether a factory gauge or a replacement, there is friction between the wood and the saw table as you push the work across the surface. The larger the board, the greater the friction - and the greater the tendency for the board to twist or creep as you make your crosscut. A crosscut sled works like a miter gauge, but it also supports the wood and eliminates the friction. Crosscuts - particularly cuts in large boards - are smoother and more accurate with a sled. While you can't easily make your own miter gauge, a shop-made crosscut sled is definitely an option. There are two distinct styles of shop-made sleds, one that slides on the left of the blade and another that slides on both sides of the blade, with a kerf cut in the sled to allow blade passage. Both have benefits. The left-sliding sled (shown above) supports the workpiece for square and mitered cuts, but it does not support the waste piece during or after the cut. The "fall-off" piece can truly fall off and without proper caution can become a hazard. This can also cause tear-out at the end of the cut. One solution is to add a second fixed table of the same height as the sled to the right of the blade. Another option is to use a larger wooden sled that rides in both miter slots, allowing you to support the workpiece on both sides of the blade. It also will always be set for a square, 90° cut, but will not easily accommodate mitered cuts. Sliding Tables Like a crosscut sled, a sliding table supports the work so you can crosscut large stock accurately and easily. But unlike a miter sled the supporting surface is flush with the saw table. And instead of sliding back and forth in the miter gauge slots, this accessory rolls back and forth on bearings and rails. A sliding table usually replaces the left table wing on your saw and will require you to relocate, or shorten the fence rails. This will also limit how far you can position the fence to the left of the blade, so be mindful of this complication. Most sliding tables not only allow moving larger panels past the blade effortlessly, but they also have stops mounted on the crosscut fence that can accommodate up to a 62" crosscut. The A two-sided miter sled allows equal support on either side of the blade and also functions as a partial blade guard. While stops can also be added into this design (as shown) it doesn't easily allow for adjustable miter cuts. popwood.com 54 |