Popular Woodworking 2005-04 № 147, страница 97

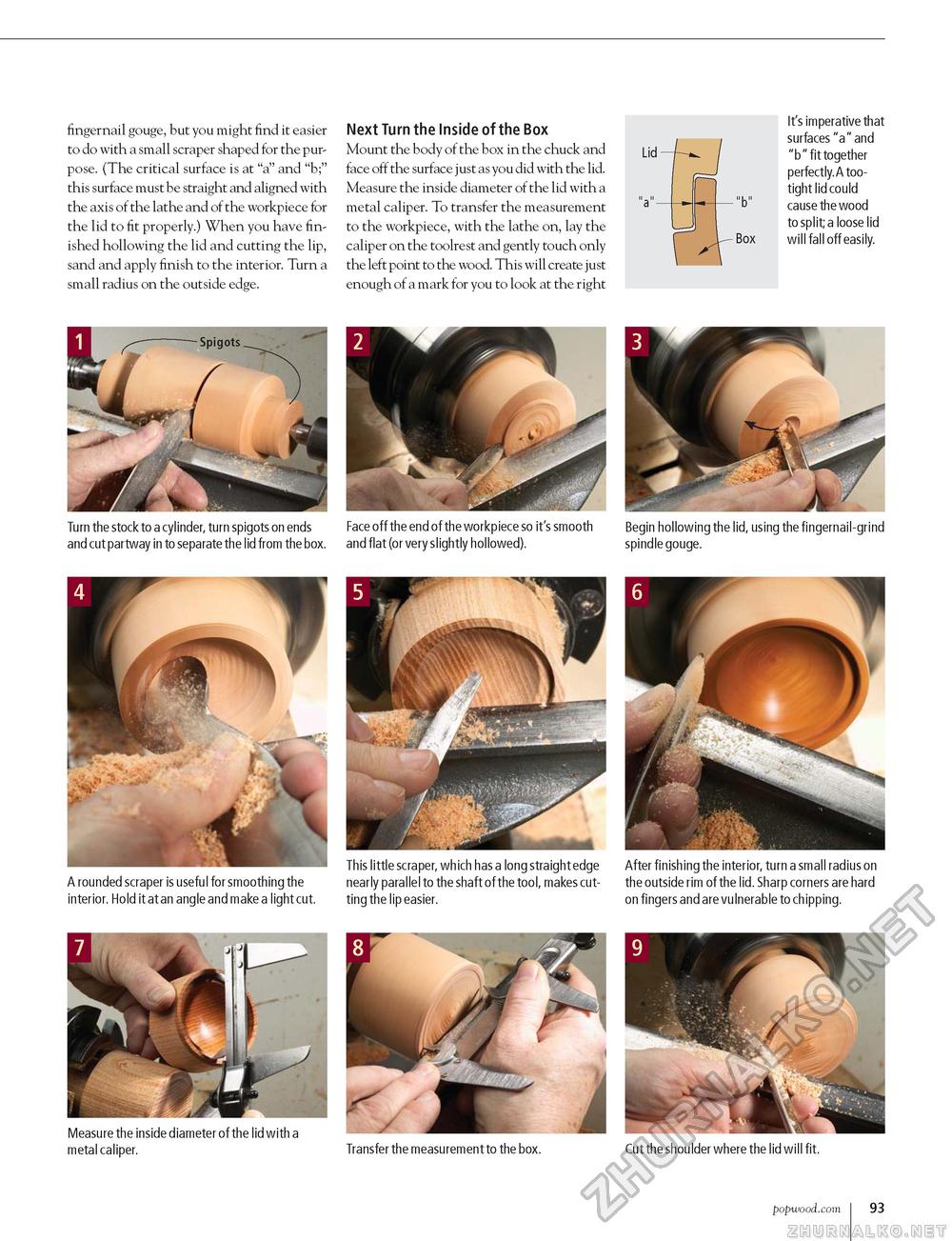

fingernail gouge, but you might find it easier to do with a small scraper shaped for the purpose. (The critical surface is at "a" and "b;" this surface must be straight and aligned with the axis of the lathe and of the workpiece for the lid to fit properly.) When you have finished hollowing the lid and cutting the lip, sand and apply finish to the interior. Turn a small radius on the outside edge. Next Turn the Inside of the Box Mount the body of the box in the chuck and face off the surface just as you did with the lid. Measure the inside diameter of the lid with a metal caliper. To transfer the measurement to the workpiece, with the lathe on, lay the caliper on the toolrest and gently touch only the left point to the wood. This will create just enough of a mark for you to look at the right It's imperative that surfaces "a" and "b" fit together perfectly. A too-tight lid could cause the wood to split; a loose lid will fall off easily. Turn the stock to a cylinder, turn spigots on ends Face off the end of the workpiece so it's smooth and cut partway in to separate the lid from the box. and flat (or very slightly hollowed). Begin hollowing the lid, using the fingernail-grind spindle gouge. A rounded scraper is useful for smoothing the interior. Hold it at an angle and make a light cut. ting the lip easier. This little scraper, which has a long straight edge After finishing the interior, turn a small radius on nearly parallel to the shaft of the tool, makes cut- the outside rim of the lid. Sharp corners are hard on fingers and are vulnerable to chipping. Measure the inside diameter of the lid with a metal caliper. Transfer the measurement to the box. Cut the shoulder where the lid will fit. popwood.com 93 |