Popular Woodworking 2005-06 № 148, страница 79

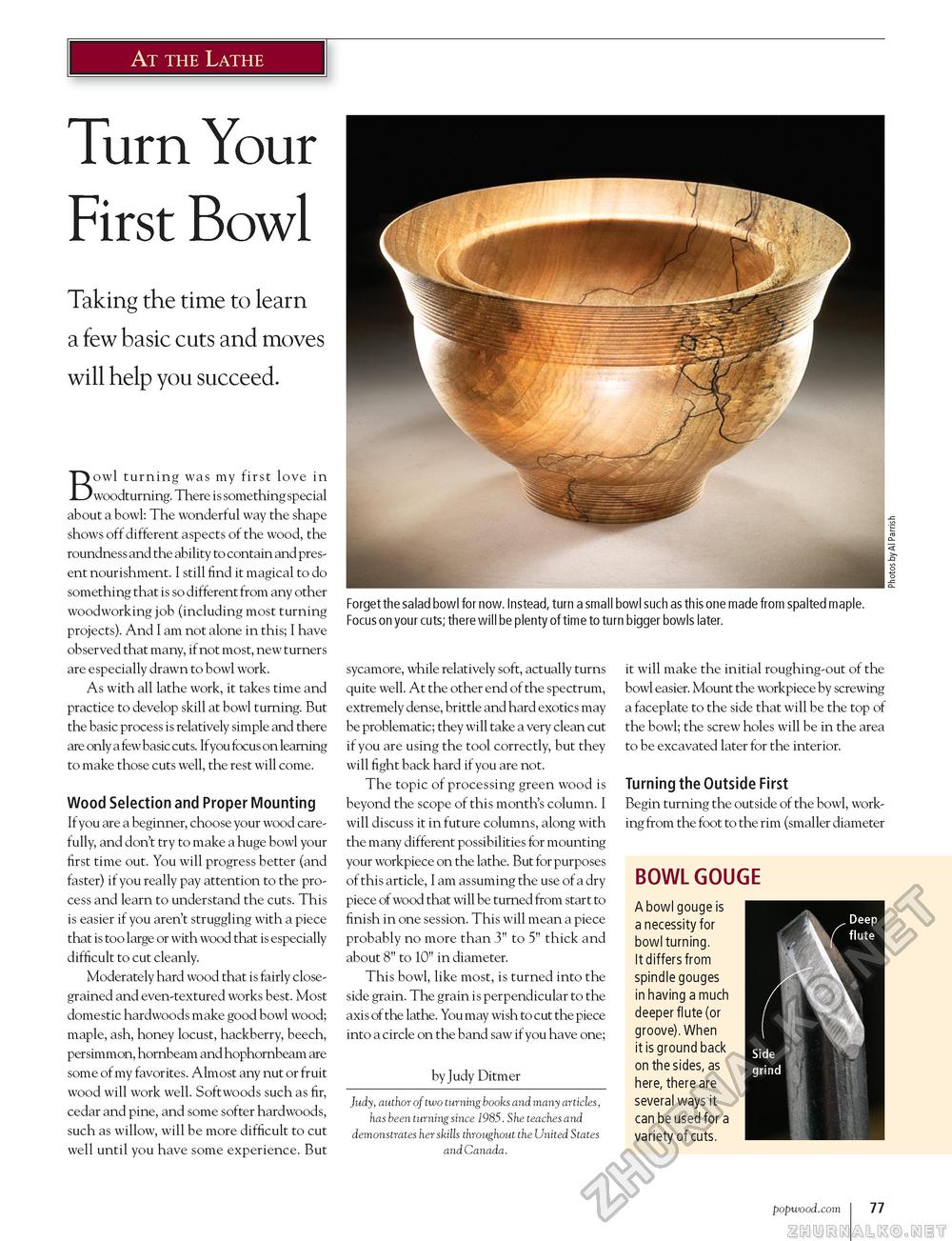

At the Lathe Turn Your First Bowl Taking the time to learn a few basic cuts and moves will help you succeed. Bowl turning was my first love in woodturning. There is something special about a bowl: The wonderful way the shape shows off different aspects of the wood, the roundness and the ability to contain and present nourishment. I still find it magical to do something that is so different from any other woodworking job (including most turning projects). And I am not alone in this; I have observed that many, if not most, new turners are especially drawn to bowl work. As with all lathe work, it takes time and practice to develop skill at bowl turning. But the basic process is relatively simple and there are only a few basic cuts. Ifyou focus on learning to make those cuts well, the rest will come. Wood Selection and Proper Mounting If you are a beginner, choose your wood carefully, and don't try to make a huge bowl your first time out. You will progress better (and faster) if you really pay attention to the process and learn to understand the cuts. This is easier if you aren't struggling with a piece that is too large or with wood that is especially difficult to cut cleanly. Moderately hard wood that is fairly close-grained and even-textured works best. Most domestic hardwoods make good bowl wood; maple, ash, honey locust, hackberry, beech, persimmon, hornbeam and hophornbeam are some of my favorites. Almost any nut or fruit wood will work well. Softwoods such as fir, cedar and pine, and some softer hardwoods, such as willow, will be more difficult to cut well until you have some experience. But Forget the salad bowl for now. Instead, turn a small bowl such as this one made from spalted maple. Focus on your cuts; there will be plenty of time to turn bigger bowls later. sycamore, while relatively soft, actually turns quite well. At the other end of the spectrum, extremely dense, brittle and hard exotics may be problematic; they will take a very clean cut if you are using the tool correctly, but they will fight back hard if you are not. The topic of processing green wood is beyond the scope of this month's column. I will discuss it in future columns, along with the many different possibilities for mounting your workpiece on the lathe. But for purposes of this article, I am assuming the use of a dry piece of wood that will be turned from start to finish in one session. This will mean a piece probably no more than 3" to 5" thick and about 8" to 10" in diameter. This bowl, like most, is turned into the side grain. The grain is perpendicular to the axis of the lathe. You may wish to cut the piece into a circle on the band saw if you have one; by Judy Ditmer Judy, author of two turning books and many articles, has been turning since 1985. She teaches and demonstrates her skills throughout the United States and Canada. it will make the initial roughing-out of the bowl easier. Mount the workpiece by screwing a faceplate to the side that will be the top of the bowl; the screw holes will be in the area to be excavated later for the interior. Turning the Outside First Begin turning the outside of the bowl, working from the foot to the rim (smaller diameter BOWL GOUGE A bowl gouge is a necessity for bowl turning. It differs from spindle gouges in having a much deeper flute (or groove). When it is ground back on the sides, as here, there are several ways it can be used for a variety of cuts. popwood.com 77 |