Popular Woodworking 2005-08 № 149, страница 22

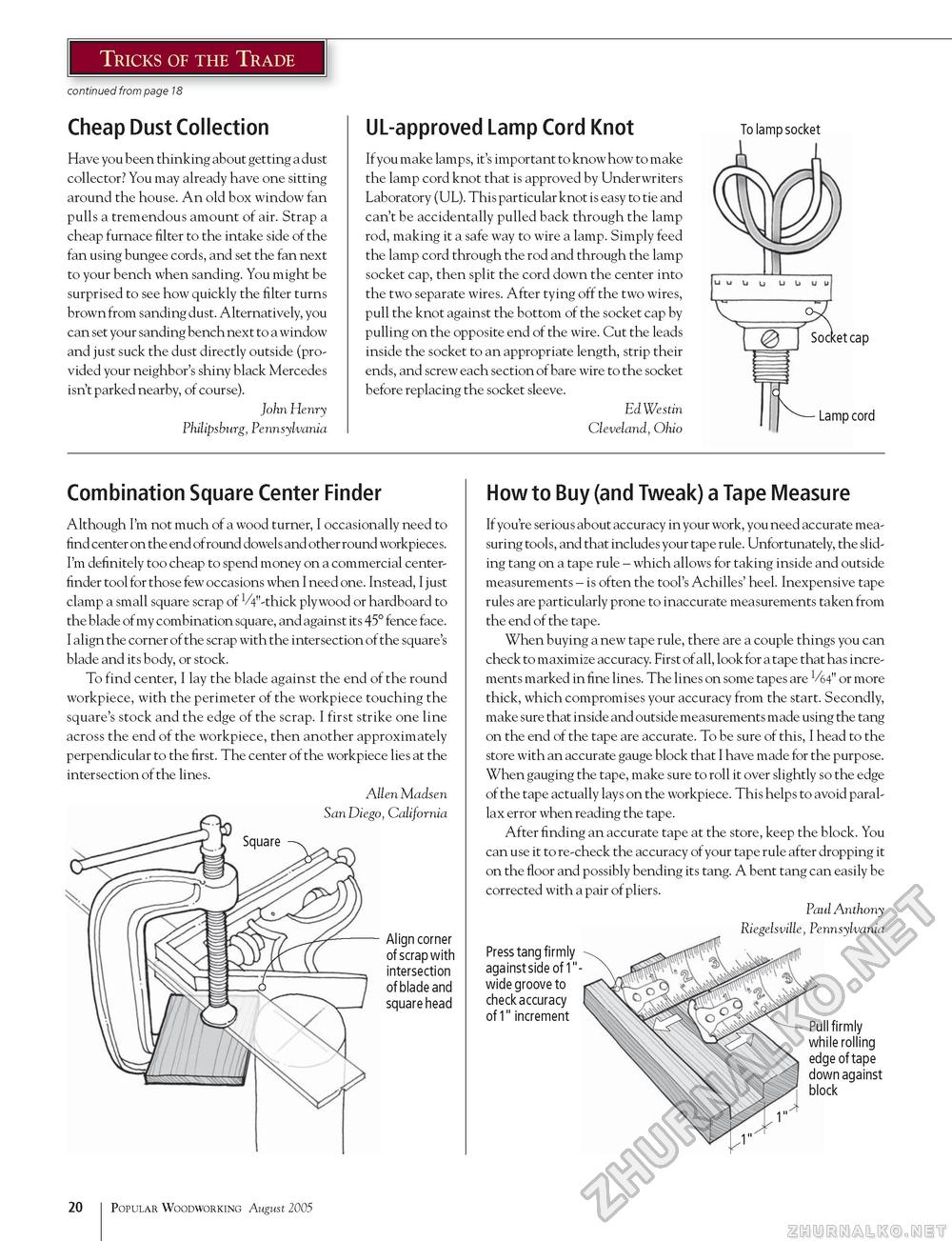

Tricks of the Trade continued from page 18 Cheap Dust Collection Have you been thinking about getting a dust collector? You may already have one sitting around the house. An old box window fan pulls a tremendous amount of air. Strap a cheap furnace filter to the intake side of the fan using bungee cords, and set the fan next to your bench when sanding. You might be surprised to see how quickly the filter turns brown from sanding dust. Alternatively, you can set your sanding bench next to a window and just suck the dust directly outside (provided your neighbor's shiny black Mercedes isn't parked nearby, of course). John Henry Philipsburg, Pennsylvania UL-approved Lamp Cord Knot If you make lamps, it's important to know how to make the lamp cord knot that is approved by Underwriters Laboratory (UL). This particular knot is easy to tie and can't be accidentally pulled back through the lamp rod, making it a safe way to wire a lamp. Simply feed the lamp cord through the rod and through the lamp socket cap, then split the cord down the center into the two separate wires. After tying off the two wires, pull the knot against the bottom of the socket cap by pulling on the opposite end of the wire. Cut the leads inside the socket to an appropriate length, strip their ends, and screw each section of bare wire to the socket before replacing the socket sleeve. Ed Westin Cleveland, Ohio To lamp socket Combination Square Center Finder Although I'm not much of a wood turner, I occasionally need to find center on the end of round dowels and other round workpiece s. I'm definitely too cheap to spend money on a commercial center-finder tool for those few occasions when I need one. Instead, I just clamp a small square scrap of V4"-thick plywood or hardboard to the blade of my combination square, and against its 45° fence face. I align the corner of the scrap with the intersection of the square's blade and its body, or stock. To find center, I lay the blade against the end of the round workpiece, with the perimeter of the workpiece touching the square's stock and the edge of the scrap. I first strike one line across the end of the workpiece, then another approximately perpendicular to the first. The center of the workpiece lies at the intersection of the lines. Allen Madsen San Diego, California Align corner of scrap with intersection of blade and square head How to Buy (and Tweak) a Tape Measure If you're serious about accuracy in your work, you need accurate measuring tools, and that includes your tape rule. Unfortunately, the sliding tang on a tape rule - which allows for taking inside and outside measurements - is often the tool's Achilles' heel. Inexpensive tape rules are particularly prone to inaccurate measurements taken from the end of the tape. When buying a new tape rule, there are a couple things you can check to maximize accuracy. First of all, look for a tape that has increments marked in fine lines. The lines on some tapes are V64" or more thick, which compromises your accuracy from the start. Secondly, make sure that inside and outside measurements made using the tang on the end of the tape are accurate. To be sure of this, I head to the store with an accurate gauge block that I have made for the purpose. When gauging the tape, make sure to roll it over slightly so the edge of the tape actually lays on the workpiece. This helps to avoid parallax error when reading the tape. After finding an accurate tape at the store, keep the block. You can use it to re-check the accuracy of your tape rule after dropping it on the floor and possibly bending its tang. A bent tang can easily be corrected with a pair of pliers. Paul Anthony Riegelsville, Pennsylvania Press tang firmly against side of 1"-wide groove to check accuracy of 1" increment , „r Pull firmly while rolling edge of tape down against block 20 Popular Woodworking August 2005 |