Popular Woodworking 2005-11 № 151, страница 50

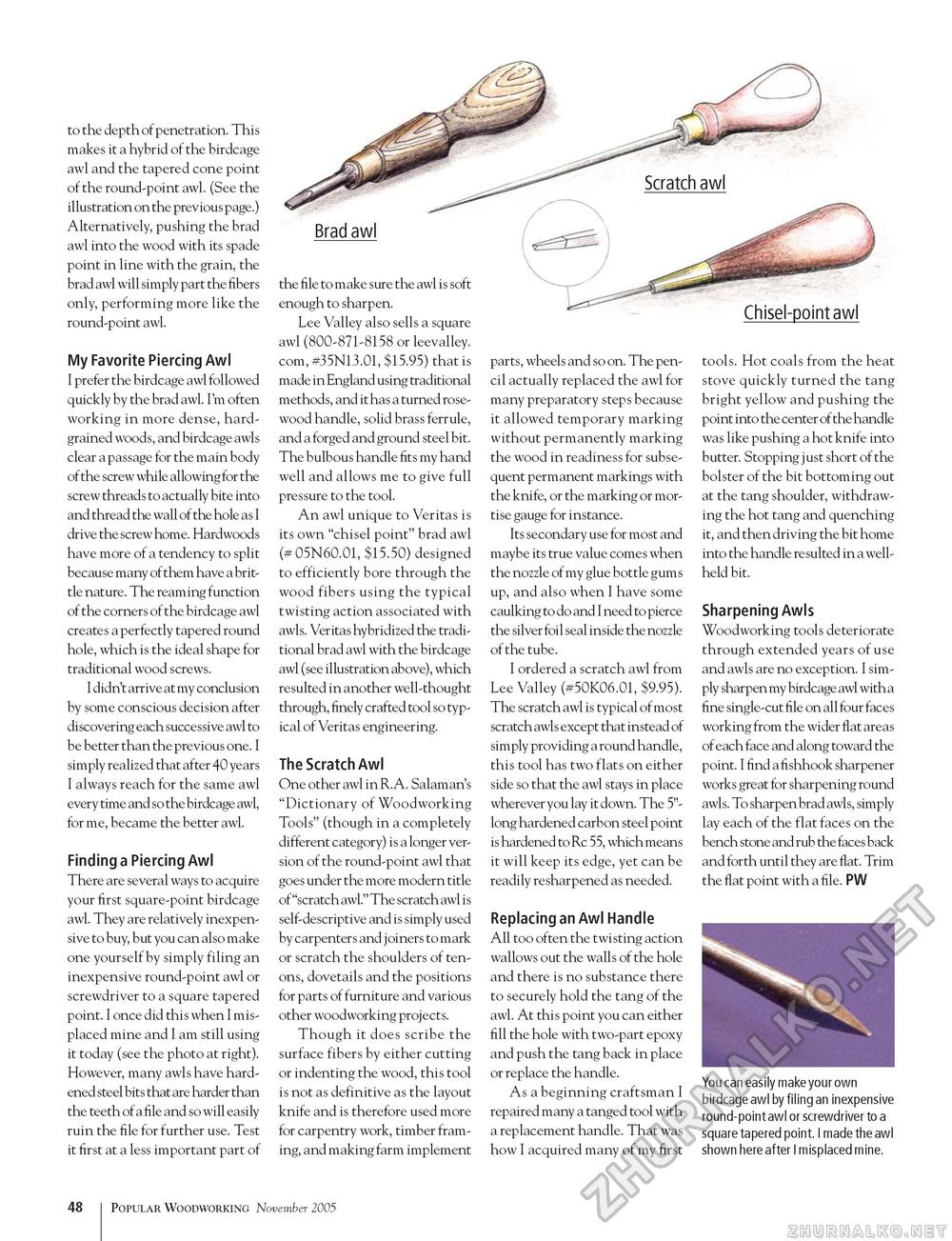

to the depth of penetration. This makes it a hybrid of the birdcage awl and the tapered cone point of the round-point awl. (See the illustration on the previous page.) Alternatively, pushing the brad awl into the wood with its spade point in line with the grain, the brad awl will simply part the fibers only, performing more like the round-point awl. My Favorite Piercing Awl I prefer the birdcage awl followed quickly by the brad awl. I'm often working in more dense, hard-grained woods, and birdcage awls clear a passage for the main body of the screw while allowing for the screw threads to actually bite into and thread the wall of the hole as I drive the screw home. Hardwoods have more of a tendency to split because many of them have a brittle nature. The reaming function of the corners of the birdcage awl creates a perfectly tapered round hole, which is the ideal shape for traditional wood screws. I didn't arrive at my conclusion by some conscious decision after discovering each successive awl to be better than the previous one. I simply realized that after 40 years I always reach for the same awl every time and so the birdcage awl, for me, became the better awl. Finding a Piercing Awl There are several ways to acquire your first square-point birdcage awl. They are relatively inexpensive to buy, but you can also make one yourself by simply filing an inexpensive round-point awl or screwdriver to a square tapered point. I once did this when I misplaced mine and I am still using it today (see the photo at right). However, many awls have hardened steel bits that are harder than the teeth of a file and so will easily ruin the file for further use. Test it first at a less important part of Brad awl the file to make sure the awl is soft enough to sharpen. Lee Valley also sells a square awl (800-871-8158 or leevalley. com, #35N13.01, $15.95) that is made in England using traditional methods, and it has a turned rosewood handle, solid brass ferrule, and a forged and ground steel bit. The bulbous handle fits my hand well and allows me to give full pressure to the tool. An awl unique to Veritas is its own "chisel point" brad awl (# 05N60.01, $15.50) designed to efficiently bore through the wood fibers using the typical twisting action associated with awls. Veritas hybridized the traditional brad awl with the birdcage awl (see illustration above), which resulted in another well-thought through, finely crafted tool so typical of Veritas engineering. The Scratch Awl One other awl in R. A. Salaman's "Dictionary of Woodworking Tools" (though in a completely different category) is a longer version of the round-point awl that goes under the more modern title of "scratch awl." The scratch awl is self-descriptive and is simply used by carpenters and joiners to mark or scratch the shoulders of tenons, dovetails and the positions for parts of furniture and various other woodworking projects. Though it does scribe the surface fibers by either cutting or indenting the wood, this tool is not as definitive as the layout knife and is therefore used more for carpentry work, timber framing, and making farm implement / > parts, wheels and so on. The pencil actually replaced the awl for many preparatory steps because it allowed temporary marking without permanently marking the wood in readiness for subsequent permanent markings with the knife, or the marking or mortise gauge for instance. Its secondary use for most and maybe its true value comes when the nozzle of my glue bottle gums up, and also when I have some caulking to do and I need to pierce the silver foil seal inside the nozzle of the tube. I ordered a scratch awl from Lee Valley (#50K06.01, $9.95). The scratch awl is typical of most scratch awls except that instead of simply providing a round handle, this tool has two flats on either side so that the awl stays in place wherever you lay it down. The 5"-long hardened carbon steel point is hardened to Rc 55, which means it will keep its edge, yet can be readily resharpened as needed. Replacing an Awl Handle All too often the twisting action wallows out the walls of the hole and there is no substance there to securely hold the tang of the awl. At this point you can either fill the hole with two-part epoxy and push the tang back in place or replace the handle. As a beginning craftsman I repaired many a tanged tool with a replacement handle. That was how I acquired many of my first Chisel-point awl tools. Hot coals from the heat stove quickly turned the tang bright yellow and pushing the point into the center of the handle was like pushing a hot knife into butter. Stopping just short of the bolster of the bit bottoming out at the tang shoulder, withdrawing the hot tang and quenching it, and then driving the bit home into the handle re sulted in a well-held bit. Sharpening Awls Woodworking tools deteriorate through extended years of use and awls are no exception. I simply sharpen my birdcage awl with a fine single-cut file on all four faces working from the wider flat areas of each face and along toward the point. I find a fishhook sharpener works great for sharpening round awls. To sharpen brad awls, simply lay each of the flat faces on the bench stone and rub the faces back and forth until they are flat. Trim the flat point with a file. PW You can easily make your own birdcage awl by filing an inexpensive round-point awl or screwdriver to a square tapered point. I made the awl shown here after I misplaced mine. 48 Popular Woodworking November 2005 |