Popular Woodworking 2005-11 № 151, страница 53

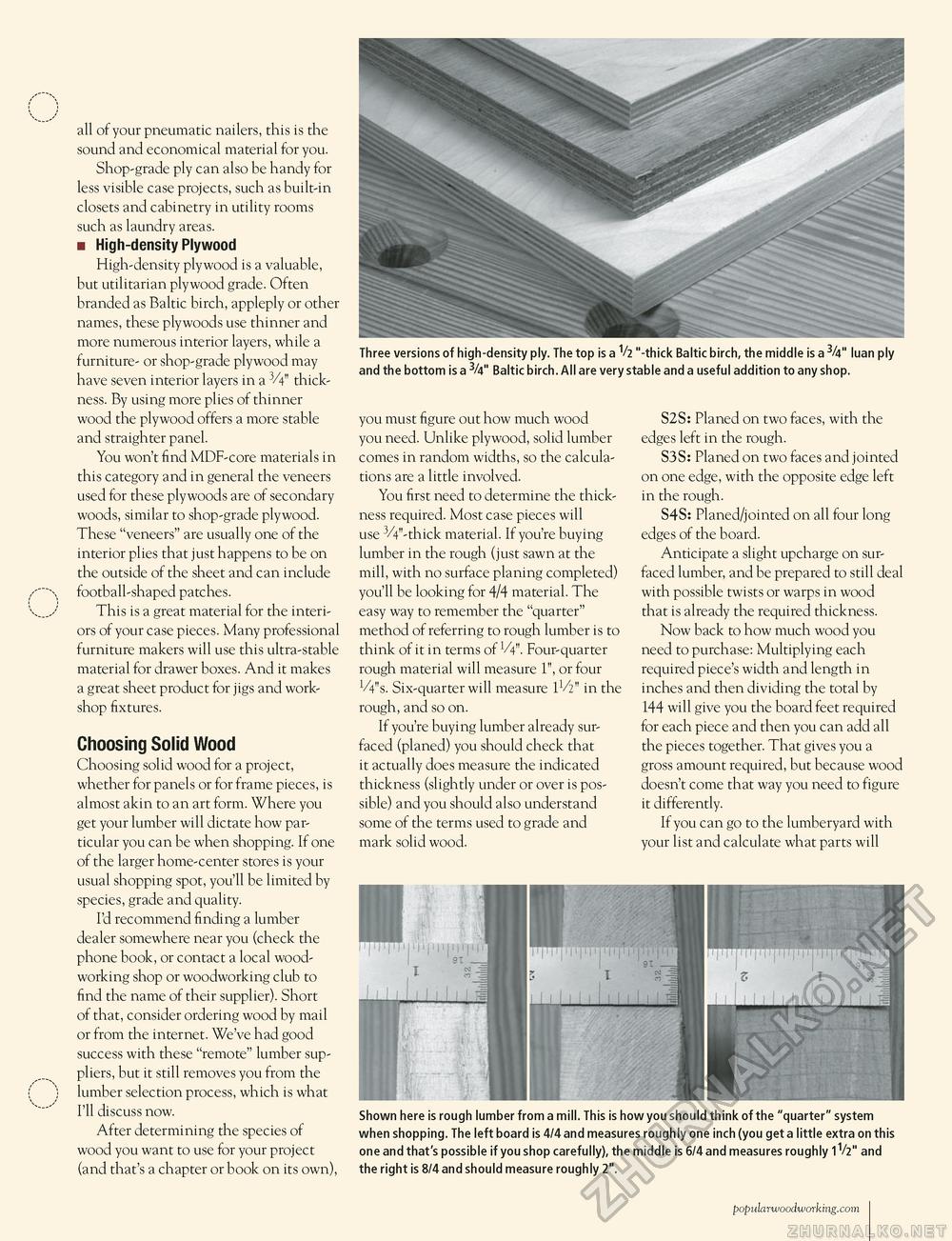

Three versions of high-density ply. The top is a V2 "-thick Baltic birch, the middle is a 3/4" luan ply and the bottom is a 3/4" Baltic birch. All are very stable and a useful addition to any shop. all of your pneumatic nailers, this is the sound and economical material for you. Shop-grade ply can also be handy for less visible case projects, such as built-in closets and cabinetry in utility rooms such as laundry areas. ■ High-density Plywood High-density plywood is a valuable, but utilitarian plywood grade. Often branded as Baltic birch, appleply or other names, these plywoods use thinner and more numerous interior layers, while a furniture- or shop-grade plywood may have seven interior layers in a 3/4" thickness. By using more plies of thinner wood the plywood offers a more stable and straighter panel. You won't find MDF-core materials in this category and in general the veneers used for these plywoods are of secondary woods, similar to shop-grade plywood. These "veneers" are usually one of the interior plies that just happens to be on the outside of the sheet and can include football-shaped patches. This is a great material for the interiors of your case pieces. Many professional furniture makers will use this ultra-stable material for drawer boxes. And it makes a great sheet product for jigs and workshop fixtures. Choosing Solid Wood Choosing solid wood for a project, whether for panels or for frame pieces, is almost akin to an art form. Where you get your lumber will dictate how particular you can be when shopping. If one of the larger home-center stores is your usual shopping spot, you'll be limited by species, grade and quality. I'd recommend finding a lumber dealer somewhere near you (check the phone book, or contact a local woodworking shop or woodworking club to find the name of their supplier). Short of that, consider ordering wood by mail or from the internet. We've had good success with these "remote" lumber suppliers, but it still removes you from the lumber selection process, which is what I'll discuss now. After determining the species of wood you want to use for your project (and that's a chapter or book on its own), you must figure out how much wood you need. Unlike plywood, solid lumber comes in random widths, so the calculations are a little involved. You first need to determine the thickness required. Most case pieces will use 3/4"-thick material. If you're buying lumber in the rough (just sawn at the mill, with no surface planing completed) you'll be looking for 4/4 material. The easy way to remember the "quarter" method of referring to rough lumber is to think of it in terms of V4". Four-quarter rough material will measure 1", or four ^"s. Six-quarter will measure IV2" in the rough, and so on. If you're buying lumber already surfaced (planed) you should check that it actually does measure the indicated thickness (slightly under or over is possible) and you should also understand some of the terms used to grade and mark solid wood. s2s: Planed on two faces, with the edges left in the rough. s3s: Planed on two faces and jointed on one edge, with the opposite edge left in the rough. s4s: Planed/jointed on all four long edges of the board. Anticipate a slight upcharge on surfaced lumber, and be prepared to still deal with possible twists or warps in wood that is already the required thickness. Now back to how much wood you need to purchase: Multiplying each required piece's width and length in inches and then dividing the total by 144 will give you the board feet required for each piece and then you can add all the pieces together. That gives you a gross amount required, but because wood doesn't come that way you need to figure it differently. If you can go to the lumberyard with your list and calculate what parts will

Shown here is rough lumber from a mill. This is how you should think of the "quarter" system when shopping. The left board is 4/4 and measures roughly one inch (you get a little extra on this one and that's possible if you shop carefully), the middle is 6/4 and measures rou ghly 11/2" and the right is 8/4 and should measure roughly 2". popularwoodworking.com 53 |

|||||||||