Popular Woodworking 2005-11 № 151, страница 52

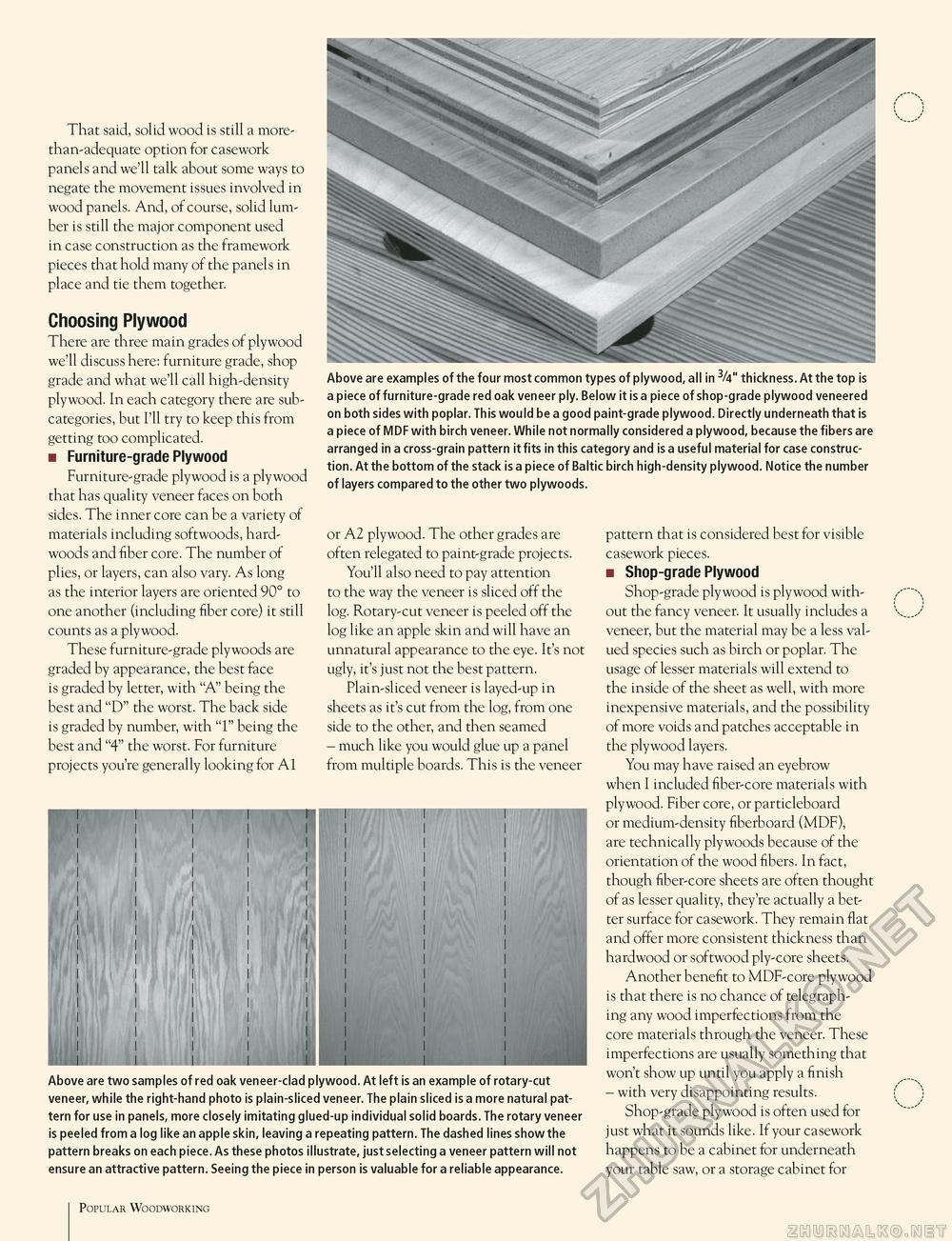

That said, solid wood is still a more-than-adequate option for casework panels and we'll talk about some ways to negate the movement issues involved in wood panels. And, of course, solid lumber is still the major component used in case construction as the framework pieces that hold many of the panels in place and tie them together. Choosing Plywood There are three main grades of plywood we'll discuss here: furniture grade, shop grade and what we'll call high-density plywood. In each category there are sub-categories, but I'll try to keep this from getting too complicated. ■ Furniture-grade Plywood Furniture-grade plywood is a plywood that has quality veneer faces on both sides. The inner core can be a variety of materials including softwoods, hardwoods and fiber core. The number of plies, or layers, can also vary. As long as the interior layers are oriented 90° to one another (including fiber core) it still counts as a plywood. These furniture-grade plywoods are graded by appearance, the best face is graded by letter, with "A" being the best and "D" the worst. The back side is graded by number, with "1" being the best and "4" the worst. For furniture projects you're generally looking for A1 Above are examples of the four most common types of plywood, all in 3/4" thickness. At the top is a piece of furniture-grade red oak veneer ply. Below it is a piece of shop-grade plywood veneered on both sides with poplar. This would be a good paint-grade plywood. Directly underneath that is a piece of MDF with birch veneer. While not normally considered a plywood, because the fibers are arranged in a cross-grain pattern it fits in this category and is a useful material for case construction. At the bottom of the stack is a piece of Baltic birch high-density plywood. Notice the number of layers compared to the other two plywoods. or A2 plywood. The other grades are often relegated to paint-grade projects. You'll also need to pay attention to the way the veneer is sliced off the log. Rotary-cut veneer is peeled off the log like an apple skin and will have an unnatural appearance to the eye. It's not ugly, it's just not the best pattern. Plain-sliced veneer is layed-up in sheets as it's cut from the log, from one side to the other, and then seamed - much like you would glue up a panel from multiple boards. This is the veneer Above are two samples of red oak veneer-clad plywood. At left is an example of rotary-cut veneer, while the right-hand photo is plain-sliced veneer. The plain sliced is a more natural pattern for use in panels, more closely imitating glued-up individual solid boards. The rotary veneer is peeled from a log like an apple skin, leaving a repeating pattern. The dashed lines show the pattern breaks on each piece. As these photos illustrate, just selecting a veneer pattern will not ensure an attractive pattern. Seeing the piece in person is valuable for a reliable appearance. pattern that is considered best for visible casework pieces. ■ Shop-grade Plywood Shop-grade plywood is plywood without the fancy veneer. It usually includes a veneer, but the material may be a less valued species such as birch or poplar. The usage of lesser materials will extend to the inside of the sheet as well, with more inexpensive materials, and the possibility of more voids and patches acceptable in the plywood layers. You may have raised an eyebrow when I included fiber-core materials with plywood. Fiber core, or particleboard or medium-density fiberboard (MDF), are technically plywoods because of the orientation of the wood fibers. In fact, though fiber-core sheets are often thought of as lesser quality, they're actually a better surface for casework. They remain flat and offer more consistent thickness than hardwood or softwood ply-core sheets. Another benefit to MDF-core plywood is that there is no chance of telegraphing any wood imperfections from the core materials through the veneer. These imperfections are usually something that won't show up until you apply a finish - with very disappointing results. Shop-grade plywood is often used for just what it sounds like. If your casework happens to be a cabinet for underneath your table saw, or a storage cabinet for Popular Woodworking |