Popular Woodworking 2005-12 № 152, страница 77

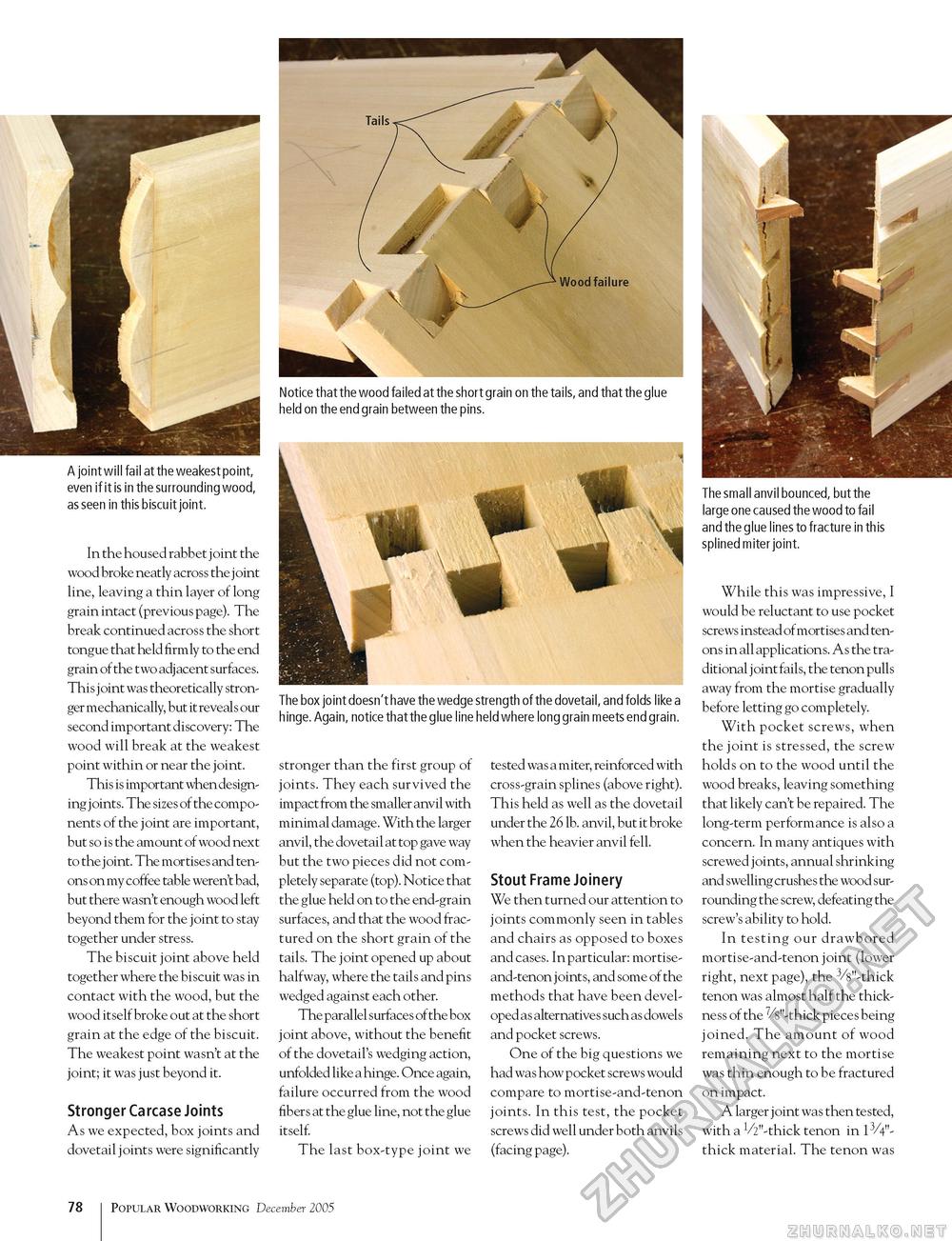

A joint will fail at the weakest point, even if it is in the surrounding wood, as seen in this biscuit joint. In the housed rabbet joint the wood broke neatly across the j oint line, leaving a thin layer of long grain intact (previous page). The break continued across the short tongue that held firmly to the end grain of the two adjacent surfaces. This joint was theoretically stronger mechanically, but it reveals our second important discovery: The wood will break at the weakest point within or near the joint. This is important when designing joints. The sizes of the components of the joint are important, but so is the amount of wood next to the joint. The mortises and tenons on my coffee table weren't bad, but there wasn't enough wood left beyond them for the joint to stay together under stress. The biscuit joint above held together where the biscuit was in contact with the wood, but the wood itself broke out at the short grain at the edge of the biscuit. The weakest point wasn't at the joint; it was just beyond it. Stronger Carcase Joints As we expected, box joints and dovetail joints were significantly Notice that the wood failed at the short grain on the tails, and that the glue held on the end grain between the pins. The box joint doesn't have the wedge strength of the dovetail, and folds like a hinge. Again, notice that the glue line held where long grain meets end grain. stronger than the first group of joints. They each survived the impact from the smaller anvil with minimal damage. With the larger anvil, the dovetail at top gave way but the two pieces did not completely separate (top). Notice that the glue held on to the end-grain surfaces, and that the wood fractured on the short grain of the tails. The joint opened up about halfway, where the tails and pins wedged against each other. The parallel surfaces of the box joint above, without the benefit of the dovetail's wedging action, unfolded like a hinge. Once again, failure occurred from the wood fibers at the glue line, not the glue itself. The last box-type joint we tested was a miter, reinforced with cross-grain splines (above right). This held as well as the dovetail under the 26 lb. anvil, but it broke when the heavier anvil fell. Stout Frame Joinery We then turned our attention to joints commonly seen in tables and chairs as opposed to boxes and cases. In particular: mortise-and-tenon joints, and some of the methods that have been developed as alternatives such as dowels and pocket screws. One of the big questions we had was how pocket screws would compare to mortise-and-tenon joints. In this test, the pocket screws did well under both anvils (facing page). The small anvil bounced, but the large one caused the wood to fail and the glue lines to fracture in this splined miter joint. While this was impressive, I would be reluctant to use pocket screws instead of mortises and tenons in all applications. As the traditional joint fails, the tenon pulls away from the mortise gradually before letting go completely. With pocket screws, when the joint is stressed, the screw holds on to the wood until the wood breaks, leaving something that likely can't be repaired. The long-term performance is also a concern. In many antiques with screwed joints, annual shrinking and swelling crushes the wood surrounding the screw, defeating the screw's ability to hold. In testing our drawbored mortise-and-tenon joint (lower right, next page), the 3/8"-thick tenon was almost half the thickness of the 7/8"-thick pieces being joined. The amount of wood remaining next to the mortise was thin enough to be fractured on impact. A larger j oint was then te sted, with a V^'-thick tenon in 13/4"-thick material. The tenon was 78 102 Popular Woodworking December 2005 |