Popular Woodworking 2005-12 № 152, страница 81

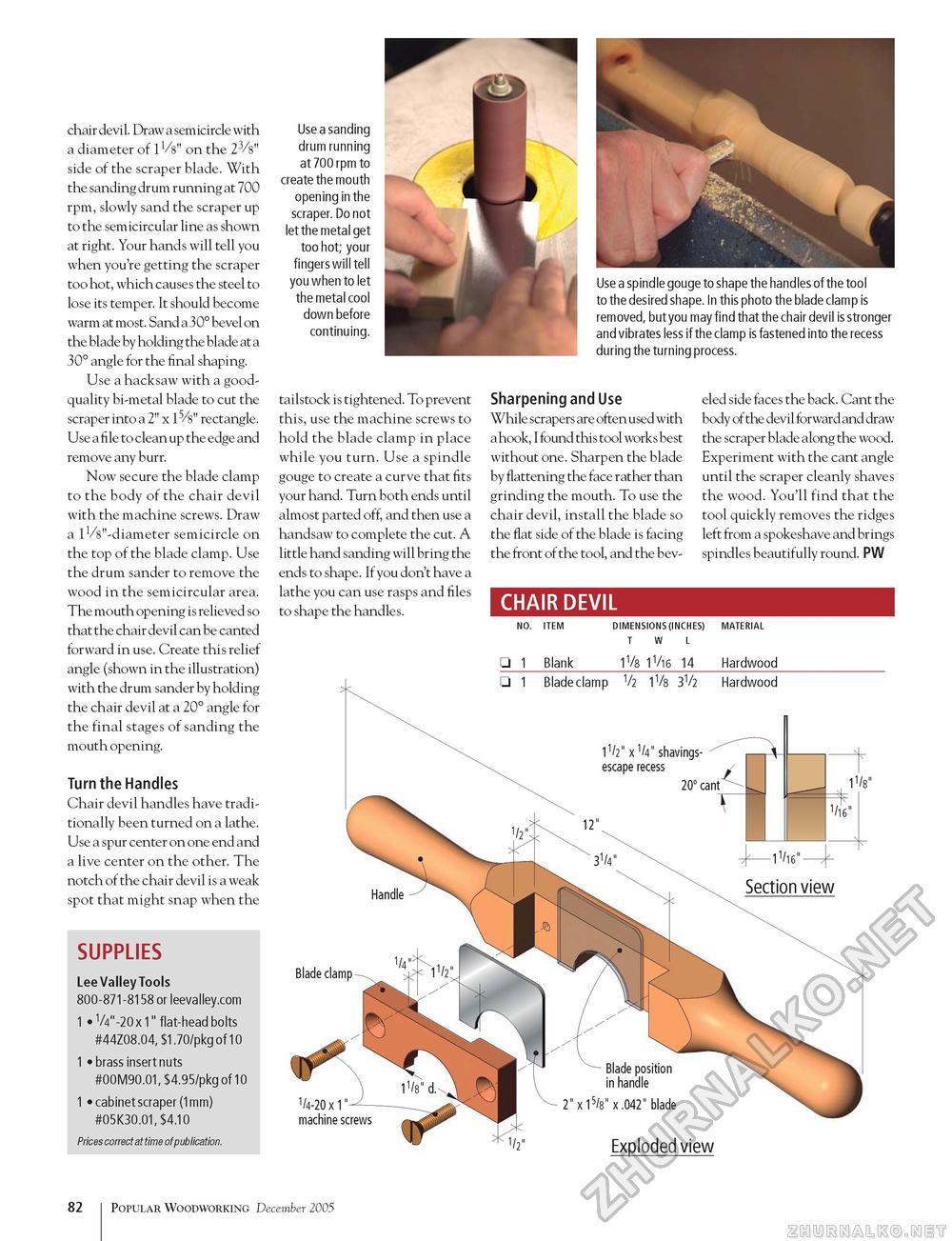

Use a spindle gouge to shape the handles of the tool to the desired shape. In this photo the blade clamp is removed, but you may find that the chair devil is stronger and vibrates less if the clamp is fastened into the recess during the turning process. chair devil. Draw a semicircle with a diameter of lV8" on the 23/s" side of the scraper blade. With the sanding drum running at 700 rpm, slowly sand the scraper up to the semicircular line as shown at right. Your hands will tell you when you're getting the scraper too hot, which causes the steel to lose its temper. It should become warm at most. Sand a 30° bevel on the blade by holding the blade at a 30° angle for the final shaping. Use a hacksaw with a good-quality bi-metal blade to cut the scraper into a 2" x rectangle. Use a file to clean up the edge and remove any burr. Now secure the blade clamp to the body of the chair devil with the machine screws. Draw a lV8"-diameter semicircle on the top of the blade clamp. Use the drum sander to remove the wood in the semicircular area. The mouth opening is relieved so that the chair devil can be canted forward in use. Create this relief angle (shown in the illustration) with the drum sander by holding the chair devil at a 20° angle for the final stages of sanding the mouth opening. Turn the Handles Chair devil handles have traditionally been turned on a lathe. Use a spur center on one end and a live center on the other. The notch of the chair devil is a weak spot that might snap when the Use a sanding drum running at 700 rpm to create the mouth opening in the scraper. Do not let the metal get too hot; your fingers will tell you when to let the metal cool down before continuing. tailstock is tightened. To prevent this, use the machine screws to hold the blade clamp in place while you turn. Use a spindle gouge to create a curve that fits your hand. Turn both ends until almost parted off, and then use a handsaw to complete the cut. A little hand sanding will bring the ends to shape. If you don't have a lathe you can use rasps and files to shape the handles. Sharpening and Use While scrapers are often used with a hook, I found this tool works best without one. Sharpen the blade by flattening the face rather than grinding the mouth. To use the chair devil, install the blade so the flat side of the blade is facing the front of the tool, and the bev- CHAIR DEVIL NO. ITEM □ 1 Blank □ 1 Blade clamp Vi lVs 3V2 eled side faces the back. Cant the body of the devil forward and draw the scraper blade along the wood. Experiment with the cant angle until the scraper cleanly shaves the wood. You'll find that the tool quickly removes the ridges left from a spokeshave and brings spindles beautifully round. PW Hardwood SUPPLIES Lee Valley Tools 800-871-8158 or leevalley.com 1 • V4"-20 x 1" flat-head bolts #44Z08.04, $1.70/pkg of 10 1 • brass insert nuts #00M90.01, $4.95/pkg of 10 1 • cabinet scraper (1mm) #05K30.01, $4.10 Prices correct at time of publication. 1V2" x 1/4" shavings-escape recess / V4-20x machine screws Exploded view DIMENSIONS (INCHES) MATERIAL T W L 1V8 1V16 14 Hardwood 102 Popular Woodworking December 2005 |