Popular Woodworking 2006-04 № 154, страница 34

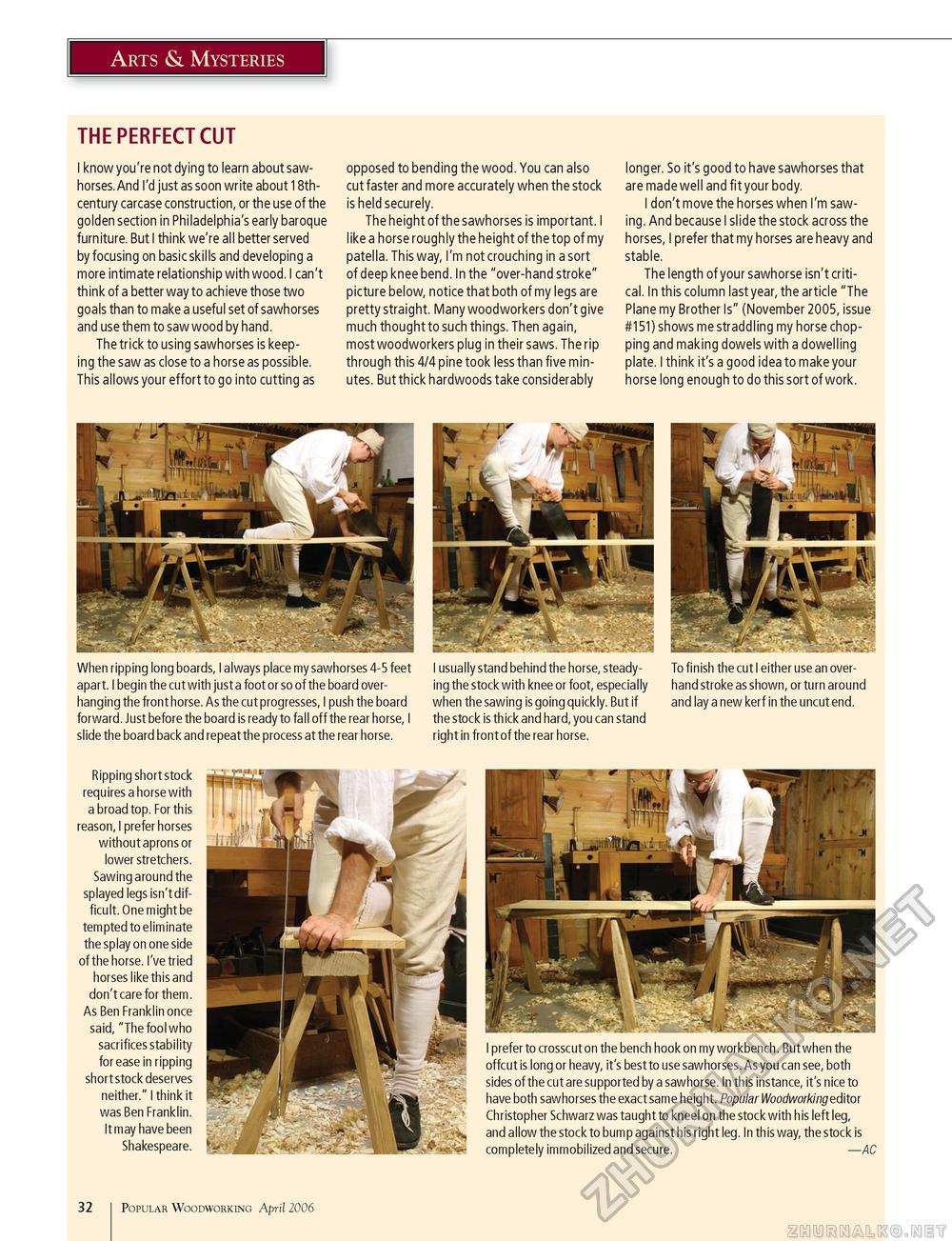

Arts & Mysteries THE PERFECT CUT I know you're not dying to learn about saw-horses. And I'd just as soon write about 18th-century carcase construction, or the use of the golden section in Philadelphia's early baroque furniture. But I think we're all better served by focusing on basic skills and developing a more intimate relationship with wood. I can't think of a better way to achieve those two goals than to make a useful set of sawhorses and use them to saw wood by hand. The trick to using sawhorses is keeping the saw as close to a horse as possible. This allows your effort to go into cutting as opposed to bending the wood. You can also cut faster and more accurately when the stock is held securely. The height of the sawhorses is important. I like a horse roughly the height of the top of my patella. This way, I'm not crouching in a sort of deep knee bend. In the "over-hand stroke" picture below, notice that both of my legs are pretty straight. Many woodworkers don't give much thought to such things. Then again, most woodworkers plug in their saws. The rip through this 4/4 pine took less than five minutes. But thick hardwoods take considerably longer. So it's good to have sawhorses that are made well and fit your body. I don't move the horses when I'm sawing. And because I slide the stock across the horses, I prefer that my horses are heavy and stable. The length of your sawhorse isn't critical. In this column last year, the article "The Plane my Brother Is" (November 2005, issue #151) shows me straddling my horse chopping and making dowels with a dowelling plate. I think it's a good idea to make your horse long enough to do this sort of work. When ripping long boards, I always place my sawhorses 4-5 feet apart. I begin the cut with just a foot or so of the board overhanging the front horse. As the cut progresses, I push the board forward. Just before the board is ready to fall off the rear horse, I slide the board back and repeat the process at the rear horse. I usually stand behind the horse, steadying the stock with knee or foot, especially when the sawing is going quickly. But if the stock is thick and hard, you can stand right in front of the rear horse. To finish the cut I either use an overhand stroke as shown, or turn around and lay a new kerf in the uncut end. Ripping short stock requires a horse with a broad top. For this reason, I prefer horses without aprons or lower stretchers. Sawing around the splayed legs isn't difficult. One might be tempted to eliminate the splay on one side of the horse. I've tried horses like this and don't care for them. As Ben Franklin once said, "The fool who sacrifices stability for ease in ripping short stock deserves neither." I think it was Ben Franklin. It may have been Shakespeare. I prefer to crosscut on the bench hook on my workbench. But when the offcut is long or heavy, it's best to use sawhorses. As you can see, both sides of the cut are supported by a sawhorse. In this instance, it's nice to have both sawhorses the exact same height. Popular Woodworking editor Christopher Schwarz was taught to kneel on the stock with his left leg, and allow the stock to bump against his right leg. In this way, the stock is completely immobilized and secure. —AC 32 Popular Woodworking April 2006 |