Popular Woodworking 2006-06 № 155, страница 56

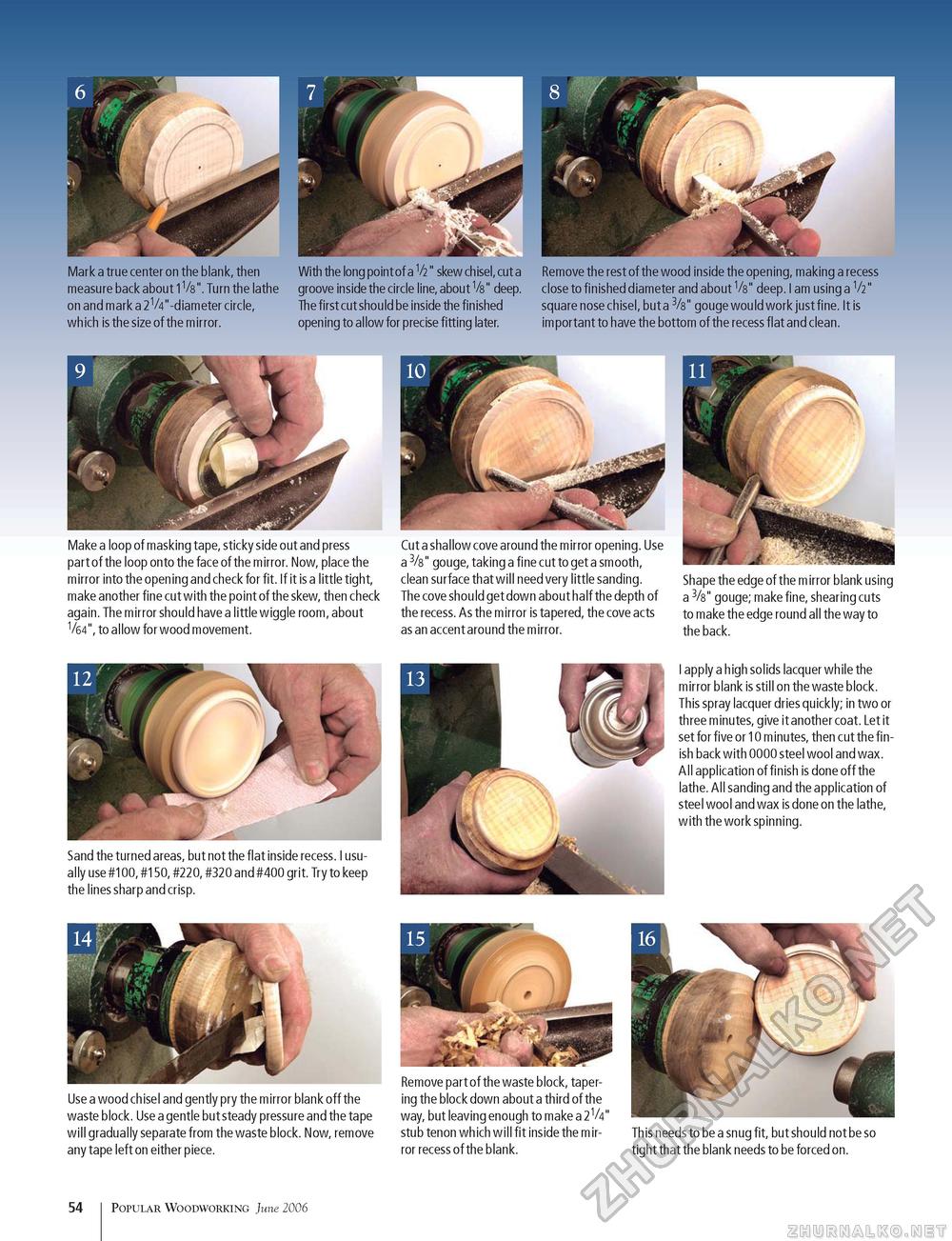

L * Mark a true center on the blank, then measure back about 1 Vs". Turn the lathe on and mark a 2V4"-diameter circle, wh ich is the size of the mirror. With the long point of a V2" skew ch isel, cut a groove inside the circle line, about Vs" deep. The first cut should be inside the finished opening to allow for precise fitting later. Remove the rest of the wood inside the opening, making a recess close to finished diameter and about Vs" deep. I am using a V2" square nose chisel, but a 3/s" gouge would work just fine. It is important to have the bottom of the recess flat and clean. Make a loop of masking tape, sticky side out and press part of the loop onto the face of the mirror. Now, place the mirror into the opening and check for fit. If it is a little tight, make another fine cut with the point of the skew, then check again. The mirror should have a little wiggle room, about V64", to allow for wood movement. Cut a shallow cove around the mirror opening. Use a 3/s" gouge, taking a fine cut to get a smooth, clean surface that will need very little sanding. The cove should get down about half the depth of the recess. As the mirror is tapered, the cove acts as an accent around the mirror. Shape the edge of the m irror blank using a 3/s" gouge; make fine, shearing cuts to make the edge round all the way to the back. Sand the turned areas, but not the flat inside recess. I usually use #100, #150, #220, #320 and #400 grit. Try to keep the lines sharp and crisp. Use a wood chisel and gently pry the mirror blank off the waste block. Use a gentle but steady pressure and the tape will gradually separate from the waste block. Now, remove any tape left on either piece. Remove part of the waste block, tapering the block down about a third of the way, but leaving enough to make a 2V4" stub tenon which will fit inside the m irror recess of the blank. I apply a high solids lacquer while the mirror blank is still on the waste block. This spray lacquer dries quickly; in two or three minutes, give it another coat. Let it set for five or 10 minutes, then cut the finish back with 0000 steel wool and wax. All application of finish is done off the lathe. All sanding and the application of steel wool and wax is done on the lathe, with the work spinning. This needs to be a snug fit, but should not be so tight that the blank needs to be forced on. 54 Popular Woodworking June 2006 |