Popular Woodworking 2006-06 № 155, страница 54

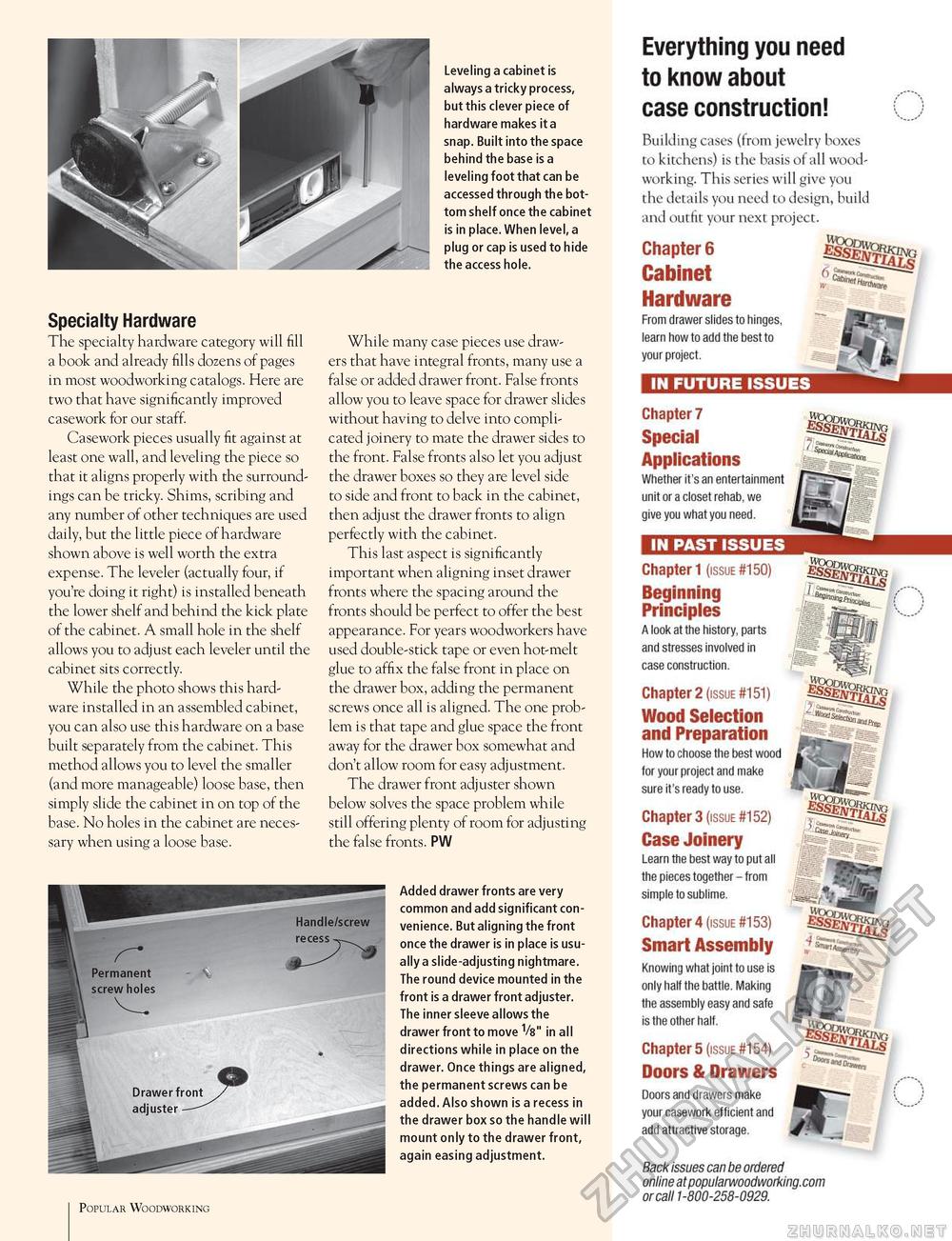

Specialty Hardware The specialty hardware category will fill a book and already fills dozens of pages in most woodworking catalogs. Here are two that have significantly improved casework for our staff. Casework pieces usually fit against at least one wall, and leveling the piece so that it aligns properly with the surroundings can be tricky. Shims, scribing and any number of other techniques are used daily, but the little piece of hardware shown above is well worth the extra expense. The leveler (actually four, if you're doing it right) is installed beneath the lower shelf and behind the kick plate of the cabinet. A small hole in the shelf allows you to adjust each leveler until the cabinet sits correctly. While the photo shows this hardware installed in an assembled cabinet, you can also use this hardware on a base built separately from the cabinet. This method allows you to level the smaller (and more manageable) loose base, then simply slide the cabinet in on top of the base. No holes in the cabinet are necessary when using a loose base. Leveling a cabinet is always a tricky process, but this clever piece of hardware makes it a snap. Built into the space behind the base is a leveling foot that can be accessed through the bottom shelf once the cabinet is in place. When level, a plug or cap is used to hide the access hole. While many case pieces use drawers that have integral fronts, many use a false or added drawer front. False fronts allow you to leave space for drawer slides without having to delve into complicated joinery to mate the drawer sides to the front. False fronts also let you adjust the drawer boxes so they are level side to side and front to back in the cabinet, then adjust the drawer fronts to align perfectly with the cabinet. This last aspect is significantly important when aligning inset drawer fronts where the spacing around the fronts should be perfect to offer the best appearance. For years woodworkers have used double-stick tape or even hot-melt glue to affix the false front in place on the drawer box, adding the permanent screws once all is aligned. The one problem is that tape and glue space the front away for the drawer box somewhat and don't allow room for easy adjustment. The drawer front adjuster shown below solves the space problem while still offering plenty of room for adjusting the false fronts. PW Added drawer fronts are very common and add significant convenience. But aligning the front once the drawer is in place is usually a slide-adjusting nightmare. The round device mounted in the front is a drawer front adjuster. The inner sleeve allows the drawer front to move Vs" in all directions while in place on the drawer. Once things are aligned, the permanent screws can be added. Also shown is a recess in the drawer box so the handle will mount only to the drawer front, again easing adjustment. Popular Woodworking |